What is machinability?

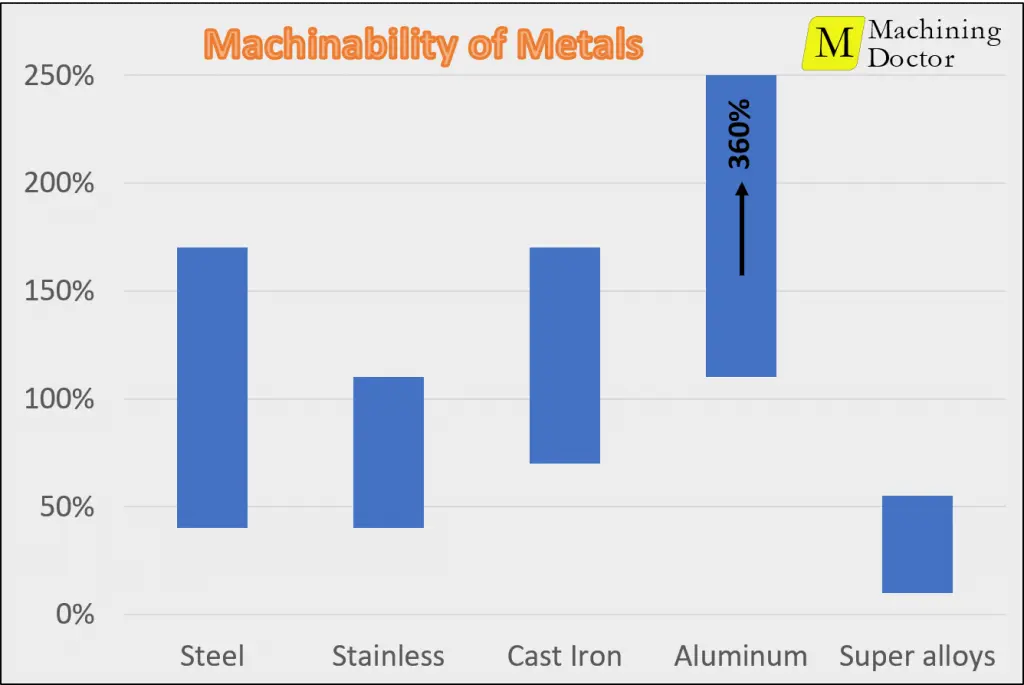

Machinability is the ease with which a metal can be machined. It is represented in percentage relative to a reference metal. A smaller value means the metal is harder to machine. Very difficult-to-machine materials can have a machinability rating of 10-20%, while very easy-to-machine materials can reach 200-400%

Why is Machinability a vital parameter?

High Machinability metals offer little resistance to being cut (Machined), while Low Machinability metals have high resistance. Higher resistance to machining means faster wear on the cutting tools, resulting in slower cutting speeds that increase the cycle time. Thus, it has a tremendous effect on the price of the product. The engineer who designs a new part has to balance the properties he needs from the metal (Such as strength, wear resistance, heat resistance, and corrosion resistance) and the part’s cost. As it is with many things in life, most of the time, better mechanical and chemical properties go hand in hand with lower machinability rates.

How is Machinability calculated?

Machinability is rated relative to the results achieved on Steel SAE 1112 at a hardness of 160 Brinell.

\( \large \frac {\text{Score of a material}}{\text{Score of SAE 1112 }} \large \times 100 \)

Hence, the machinability rating of SAE 1112 is always 100%

Various parameters influence the “Score” of each material. The choice of which parameters to use and their weight varies between the institutions that provide machinability data. Some parameters that may be used are:

- Tool life: The lifespan of the cutting tool is the primary factor in evaluating the machinability of a material. A metal that is easy to machine will generally result in a longer tool life.

- Tool wear: The wear size on the cutting edge after a given machining time is another strong signal. Materials that cause rapid tool wear are more difficult to machine.

Tool-life and tool-wear are interchangeable parameters. The institution performing the test will choose one of them as the leading parameter.

- Cutting forces: The force required to cut the material is a complementary parameter to tool-life or tool-wear.

- Machining power: The energy required to cut material is another complementary parameter to tool-life or tool wear.

- Chip Breakability: The type and characteristics of the chips produced during the machining process are an essential machinability factor. Materials that produce long, stringy chips are more difficult to machine than materials that produce short, curly chips.

Be Aware

Machinability is not a definite formal figure, like hardness or density, and there is no official standard on how to measure it. You can find different methods and different machinability rates for materials from various sources!

Determining cutting speed

We rarely want to find out the machinability rating just to learn what it is. In most cases, we are interested in the machinability value in order to estimate the cutting speed we can use for a certain material. Cutting speed depends on many factors such as stability, desired surface finish, CNC machine abilities (to name just a few). Therefore, speed and machinability recommendations are very general, and only the machinist can take the final decision depending on all the factors. The most reliable information we can learn from machinability charts is the relation between the rate of different materials on the same table. Therefore we recommend the below procedure:

- Choose a material that you are familiar with and that you are relatively confident about the cutting speed you would use for it on a relevant application. We will call this our reference material.

- Preferably, choose a reference material that is in the same material group. (List of material groups).

- Calculate the relation between the two machinability rates.

- Multiply the relation by the reference cutting speed.

- Pay attention that the machinability rating is specified for each material at a specific hardness.

- To increase the accuracy of the estimation, you should also normalize the machinability rating according to the factor between the hardness of your specific material and the hardness of the material in its annealed condition (Unless a specific hardness is listed in the machinability chart).

Example of Calculation:

You need to machine Stainless Steel 15-5PH at a harness of 38 HRC, and you are not sure what is the suitable cutting speed. However, you know that for the same application with stainless 304, you would run at 360 SFM (110 m/min).

Data for the calculations:

- From the machinability chart: 304 has MR=43%, and 15-7PH has MR=47%.

- 17-4PH has a hardness of 20 HRC in condition A. Our specific material has a hardness of 38 HRC.

- The cutting speed for SS 304 in a similar application is 360 SFM.

Calculating the cutting Speed:

What are the main factors affecting machinability?

- Chemical composition: The amount of particular elements such as Carbon, Nickel, and Lead (And many others) have a significant influence. For example, higher Nickel (Ni) content reduces Machinability, while higher Lead (Pb) content increases Machinability. However, the effect is complex, and each element can have a different impact collectively with other elements.

- Microstructure: Non-metallic inclusions can have a tremendous impact.

- Grain size: Small and well-ordered grains are easier to cut. Large disordered grains are harder to cut.

- Hardness: Both very hard and very soft materials have low Machinability. Hard materials cause fast wear on the cutting inserts, while soft material tends to be gummy and sticks to the cutting edge. Intermediate hardness yields the best results.

- Heat Treatment: Heat treatment processes can shape various properties that influence Machinability: toughness, hardness, microstructure, and stress.

- Fabrication method: Different production methods such as Hot rolled, cold rolled, cold drawn, cast or forged affect properties such as grain size, uniformity, hardness, and toughness.

Machinability Range of material Groups

Steel – ISO P

There is a wide variety of steel materials used in machining. The range of Machinability is vast and spans from about 40% for difficult to machine steels, such as bearing steel (SAE 52100 / DIN 100Cr6) up to Ledloy free-cutting steel (SAE 12L14 / DIN 9SMnPb36) that has a machinability rate of about 170%.

The Machinability is mainly affected by:

- Carbon (C): 0.3-0.5% is ideal. Lower content creates soft and gummy material, which is hard to machine. Higher content increases the strength and is also difficult to machine.

- Adding alloying elements such as Chromium (Cr), Molybdenum (Mo), and Nickel (Ni) tweaks the steel properties and tends to decrease Machinability.

Learn more about the Machinability of Steel

Stainless Steel – ISO M

Stainless Steel is generally defined as a ferrous (Fe) based material with a Chrome (Cr) content, which is higher than 12% and is usually harder to machine than steel.

Additional alloying elements such as Nickel (Ni), Chromium (Cr), Molybdenum (Mo), Niobium (Nb), and Titanium (Ti) supply different characteristics, such as resistance to corrosion and strength. Higher content of Chrome and Nickel tends to decrease Machinability.

One of the most popular materials in this group is 316, which has a machinability rate of only 36%. But other common grades, such as SAE 303 & the 400 series, have a Machinability of over 60%.

Learn more about the Machinability of Stainless Steel

Cast Iron – ISO K

Cast iron is a steel-like material with a Carbon (C) content of more than 2% and a Silicon (Si) content of 1-3%. Cast iron produces tiny chips, and because of that, it is very convenient to machine. On the other hand, it is very abrasive and creates a lot of wear. The main factors affecting the physical properties and Machinability of different types of Cast Iron is the fabrication method. (Nodular, Gray, Malleable) and hardness.

Learn more about the Machinability of Cast Iron

Nonferrous – ISO N

A group of metals with no Iron (Fe) content. Most of them are very soft, with a hardness under 150 HB. The popular materials in this group are Aluminum and Copper-based alloys. Machinability rates are very high compared with ferrous materials and typically range 200-400%. Because of this, a component made from these materials has low production costs. They are attractive as long as their inferior mechanical properties are acceptable for a given part.

Learn more about the Machinability of Aluminum

Titanium – ISO S

Titanium and Heat Resistance Alloys (HRA) have nothing in common except that they are very expensive and super hard to machine.

Titanium alloys have a very high strength-to-weight ratio. This means that it is possible to design parts that weigh much less (And very strong) when compared with other metals. For this reason, the material is popular in the aerospace industry in components with no heat exposure. Titanium also has excellent corrosion resistance and chemical stability and, therefore, is a favorite material for medical implants. The commonly used grade is Ti-6Al-4V, with a machinability rate of 20%.

Learn more about the Machinability of Titanium

Heat resistance Superalloys (HRSA) – ISO S

A group of Nickel (Ni), Cobalt (Co), and Iron (Fe) based metals. Their main feature is the ability to preserve mechanical properties and corrosion resistance also at very high temperatures. They are mainly used in jet engines, power turbines, and turbochargers. The most commonly used HRSA material is Inconel 718, which has a machinability rate of 10%.

Learn more about the Machinability of Superalloys

Machinability of Popular Materials

| sort | - | Material | MR |

|---|---|---|---|

| 0 | P | Carbon Steel (1010) | 66% |

| 0 | P | Steel 1045 | 65% |

| 0 | P | Steel 12L14 (LeadLoy) | 170% |

| 0 | P | Steel 52100 (Bearing Steel) | 40% |

| 0 | P | Alloy Steel (4340) | 57% |

| 1 | M | Martensitic Stainless Steel (420) | 45% |

| 1 | M | Austenitic Stainless Steel (316) | 40% |

| 1 | M | Stainless 17-4 PH | 43% |

| 2 | K | Gray Cast Iron (GG25) | 112% |

| 2 | K | Nodular Cast Iron (GGG50) | 100% |

| 3 | N | Brass (C360) | 170% |

| 3 | N | Aluminium (7075) | 170% |

| 4 | S | Titanium (6Al4v) | 20% |

| 4 | S | Inconel (718) | 10% |

Machinability chart (200 Materials)

(Search the table by material standard or filter it by material groups)

- Table with more than 100 materials.

- Filter by Material Group (P/M/K/N/S)

- Or Search by DIN / SAE / Wnr

| group_num | pmk | mr_group_name | Material | Machinability | BHN | SAE | DIN | WNR |

|---|---|---|---|---|---|---|---|---|

| 3 | P | Free Cutting Steel | 1112 | 100% | 0 | 1112 | 10S20 | 1.0721 |

| 3 | P | Free Cutting Steel | 1140 | 70% | 0 | 1140 | 35S20 | 1.0726 |

| 3 | P | Free Cutting Steel | 1144 | 76% | 0 | 1144 | 44SMn28 | 1.0762 |

| 3 | P | Free Cutting Steel | 1151 | 66% | 0 | 1151 | 45S20 | 1.0727 |

| 3 | P | Free Cutting Steel | 1213 | 136% | 0 | 1213 | 9SMn28 | 1.0715 |

| 3 | P | Free Cutting Steel | 1215 | 136% | 0 | 1215 | 9SMn36 | 1.0736 |

| 3 | P | Free Cutting Steel | 12L14 | 170% | 0 | 12L14 | 9SMnPb36 | 1.0737 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1006 | 55% | 0 | 1006 | St37 | 1.0037 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1008 | 60% | 0 | 1008 | St12 | 1.0201 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1010 | 66% | 0 | 1010 | Ck10 | 1.1121 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1015 | 75% | 0 | 1015 | C15 | 1.0401 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1020 | 80% | 0 | 1020 | C22 | 1.0402 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1022 | 80% | 0 | 1022 | GS.20Mn5 | 1.1133 |

| 1 | P | Low Carbon Steel (0.1-0.25%) | 1025 | 80% | 0 | 1025 | Ck25 | 1.1158 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1035 | 76% | 150 | 1035 | C35 | 1.0501 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1039 | 70% | 180 | 1039 | 40Mn4 | 1.1157 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1040 | 70% | 180 | 1040 | C40 | 1.0511 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1045 | 65% | 210 | 1045 | C45 | 1.0503 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1049 | 63% | 210 | 1049 | Cm45 | 1.1201 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1050 | 61% | 210 | 1050 | Cf53 | 1.1213 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1330 | 65% | 250 | 1330 | 28Mn6 | 1.1170 |

| 2 | P | Carbon Steel (0.26-0.50%) | 1335 | 60% | 250 | 1335 | 36Mn5 | 1.1167 |

| 4 | P | High Carbon Steel (0.51-1.0%) | 1055 | 60% | 210 | 1055 | Ck55 | 1.1203 |

| 4 | P | High Carbon Steel (0.51-1.0%) | 1060 | 57% | 210 | 1060 | C60 | 1.0601 |

| 4 | P | High Carbon Steel (0.51-1.0%) | 1070 | 51% | 210 | 1070 | Ck67 | 1.1231 |

| 4 | P | High Carbon Steel (0.51-1.0%) | 1080 | 48% | 210 | 1080 | Ck75 | 1.1248 |

| 4 | P | High Carbon Steel (0.51-1.0%) | 1086 | 47% | 210 | 1086 | Ck85 | 1.1269 |

| 4 | P | High Carbon Steel (0.51-1.0%) | 1095 | 45% | 210 | 1095 | Ck101 | 1.1274 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 4130 | 69% | 210 | 4130 | 25CrMo4 | 1.7218 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 4137 | 74% | 230 | 4137 | 34CrMo4 | 1.7220 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 4140 | 61% | 230 | 4140 | 42CrMo4 | 1.7225 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 4142 | 60% | 230 | 4142 | 41CrMo4 | 1.7223 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 4150 | 57% | 240 | 4150 | 50CrMo4 | 1.7228 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 4340 | 57% | 250 | 4340 | 35CrNiMo6 | 1.6582 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 5120 | 84% | 215 | 5120 | St52-3 | 1.0841 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 5130 | 68% | 220 | 5130 | 28Cr4 | 1.7030 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 5132 | 70% | 220 | 5132 | 34Cr4 | 1.7033 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 5140 | 63% | 230 | 5140 | 41Cr4 | 1.7035 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 52100 | 40% | 230 | 52100 | 100Cr6 | 1.3505 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 6150 | 60% | 250 | 6150 | 50CrV4 | 1.8159 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 8620 | 66% | 180 | 8620 | 21NiCrMo2 | 1.6523 |

| 6 | P | Low Alloyed Steel (180 HB Max) | 8630 | 59% | 200 | 8630 | 27CrNiMo2 | 1.6545 |

| 6 | P | Low Alloyed Steel (180 HB Max) | A105 | 66% | 190 | A105 | C22-8 | |

| 6 | P | Low Alloyed Steel (180 HB Max) | A106GB | 73% | 190 | P235GH | ||

| 6 | P | Low Alloyed Steel (180 HB Max) | A234WPB | 73% | 200 | |||

| 6 | P | Low Alloyed Steel (180 HB Max) | A234WPL6 | 73% | 200 | |||

| 6 | P | Low Alloyed Steel (180 HB Max) | A333G6 | 69% | 200 | P265GH | ||

| 6 | P | Low Alloyed Steel (180 HB Max) | A350LF2 | 73% | 200 | |||

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | 40CMD8 | 50% | 250 | 40CrMnMo7 | 1.2311 | |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | A2 | 42% | 235 | A2 | X100CrMoV51 | 1.2363 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | A6 | 33% | 250 | A6 | ||

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | D2 | 27% | 250 | D2 | X165CrMoV12 | 1.2601 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | D3 | 23% | 250 | D3 | X210Cr12 | 1.2080 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | H10 | 55% | 230 | H10 | X32CrMoV33 | 1.2365 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | H11 | 55% | 230 | H11 | X38CrMoV51 | 1.2343 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | H13 | 55% | 230 | H13 | X40CrMoV51 | 1.2344 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | M2 | 39% | 240 | M2 | HS-6-5-2C | 1.3343 |

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | M3 | 39% | 250 | M3 | ||

| 10 | P | Tool Steel and High Alloy Steel (Annealed) | O1 | 42% | 230 | O1 | 100MnCrW4 | 1.2510 |

| 12 | M | Ferritic Stainless Steel | 403 | 55% | 0 | 403 | X7Cr13 | 1.4000 |

| 12 | M | Ferritic Stainless Steel | 405 | 60% | 0 | 405 | X10CrAl13 | 1.4724 |

| 12 | M | Ferritic Stainless Steel | 410 | 55% | 0 | 410 | X10Cr13 | 1.4006 |

| 12 | M | Ferritic Stainless Steel | 416 | 90% | 0 | 41600 | X12CrS13 | 1.4005 |

| 12 | M | Ferritic Stainless Steel | 430 | 54% | 0 | 430 | X8Cr17 | 1.4016 |

| 12 | M | Ferritic Stainless Steel | 430F | 65% | 0 | 430F | X12CrMoS17 | 1.4104 |

| 12 | M | Ferritic Stainless Steel | 440A | 48% | 0 | 440A | X70CrMo15 | 1.4109 |

| 12 | M | Ferritic Stainless Steel | 446 | 36% | 0 | 446 | X10CrAl24 | 1.4762 |

| 12 | M | Ferritic Stainless Steel | Aermet 100 | 32% | 0 | AMS 6532 | ||

| 13 | M | Martensitic Stainless Steel | 420 | 45% | 245 | 420 | X20Cr13 | 1.4021 |

| 13 | M | Martensitic Stainless Steel | 420F | 55% | 245 | 420F | X30Cr13 | 1.4028 |

| 13 | M | Martensitic Stainless Steel | 431 | 48% | 220 | 431 | X22CrNi17 | 1.4057 |

| 13 | M | Martensitic Stainless Steel | 440C | 35% | 285 | 440C | X105CrMo17 | 1.4125 |

| 14 | M | Austenitic Stainless Steel | 301 | 52% | 0 | 301 | X12CrNi17-7 | 1.4310 |

| 14 | M | Austenitic Stainless Steel | 302 | 47% | 0 | 302 | X12CrNi18-9 | 1.4319 |

| 14 | M | Austenitic Stainless Steel | 303 | 72% | 0 | 303 | X8CrNiS18-9 | 1.4305 |

| 14 | M | Austenitic Stainless Steel | 304 | 43% | 0 | 304 | X5CrNi18-9 | 1.4350 |

| 14 | M | Austenitic Stainless Steel | 316 | 40% | 0 | 316 | X5CrNiMo17-13-3 | 1.4401 |

| 14 | M | Austenitic Stainless Steel | 317 | 38% | 0 | 317 | X5CrNiMo17-13 | 1.4449 |

| 14 | M | Austenitic Stainless Steel | 347 | 36% | 0 | 347 | X10CrNiNb18-9 | 1.4550 |

| 14 | M | Austenitic Stainless Steel | Custom 465 | 30% | 0 | AMS 5936 | ||

| 60 | M | Duplex Stainless Steel | Duplex 1803 (F51) | 28% | 0 | ASTM A182 Grade F51 | ||

| 60 | M | Duplex Stainless Steel | Duplex 2205 (F60 / F51) | 28% | 0 | ASTM A182 Grade F60 | X2CrNiMoN22-5-3 | 1.4462 |

| 60 | M | Duplex Stainless Steel | Duplex 2760 (F55) | 16% | 0 | ASTM A182 Grade F55 | X2CrNiMoCuWN25-7-4 | 1.4501 |

| 60 | M | Duplex Stainless Steel | Hyper Duplex 2707 (A276) | 10% | 0 | A276 | X2CrNiMoCoN28-8-5-1 | 1.4658 |

| 65 | M | Precipitation Hardening St. St. | 15-5PH | 47% | 260 | 15-5 | X4CrNiCuNb16.4 | 1.4540 |

| 65 | M | Precipitation Hardening St. St. | 17-4PH | 43% | 260 | 630 | X5CrNiCuNb16-4 | 1.4542 |

| 65 | M | Precipitation Hardening St. St. | 321 | 36% | 260 | 321 | X10CrNiTi18-9 | 1.4541 |

| 15 | K | Grey Cast Iron (180 HB Max) | GG10 | 170% | 175 | A48-20B | GG10 | 0.6010 |

| 15 | K | Grey Cast Iron (180 HB Max) | GG20 | 127% | 205 | A48-30B | GG20 | 0.6020 |

| 16 | K | Grey Cast Iron (180-260 HB) | GG25 | 112% | 220 | A48-35B | GG25 | 0.6025 |

| 16 | K | Grey Cast Iron (180-260 HB) | GG30 | 104% | 230 | A48-45B | GG30 | 0.6030 |

| 16 | K | Grey Cast Iron (180-260 HB) | GG35 | 100% | 235 | A48-50B | GG35 | 0.6035 |

| 16 | K | Grey Cast Iron (180-260 HB) | GG40 | 90% | 250 | A48-55B | GG40 | 0.6040 |

| 17 | K | Nodular cast iron (160 HB Max) | GGG-40 | 140% | 190 | 60-40-18 | GGG-40 | 0.7040 |

| 18 | K | Nodular cast iron (180-280 HB) | GGG-50 | 100% | 220 | |||

| 18 | K | Nodular cast iron (180-280 HB) | GGG-60 | 94% | 230 | 80-55-06 | GGG-60 | 0.7060 |

| 18 | K | Nodular cast iron (180-280 HB) | GGG-70 | 70% | 270 | 100-70-03 | GGG-70 | 0.7070 |

| 18 | K | Nodular cast iron (180-280 HB) | GGG-80 | 63% | 280 | 120-90-02 | GGG-80 | 0.7080 |

| 19 | K | Malleable cast iron (180 HB Max) | GTS-35-10 | 205% | 150 | 32510 | GTS-35-10 | 0.8135 |

| 19 | K | Malleable cast iron (180 HB Max) | GTS-45-06 | 149% | 175 | GTS-45-06 | ||

| 20 | K | Malleable cast iron (180-270 HB) | GTS-55-04 | 107% | 205 | |||

| 20 | K | Malleable cast iron (180-270 HB) | GTS-65-02 | 84% | 230 | 70003 | GTS-65-02 | 0.8165 |

| 20 | K | Malleable cast iron (180-270 HB) | GTS-70-02 | 62% | 265 | A220-80002 | GTS-70-02 | 0.8170 |

| 22 | N | Aluminum - Wrought - Hardened | 2011 | 280% | 0 | 2011 | AlCuBiPb | 3.1655 |

| 22 | N | Aluminum - Wrought - Hardened | 2014 | 200% | 0 | 2017 | AlCuSiMn | 3.1255 |

| 22 | N | Aluminum - Wrought - Hardened | 2017 | 200% | 0 | 2017 | AlCuMg1 | 3.1325 |

| 22 | N | Aluminum - Wrought - Hardened | 2024 | 210% | 0 | 2024 | AlCuMg2 | 3.1355 |

| 22 | N | Aluminum - Wrought - Hardened | 3003 | 260% | 0 | 3003 | AlMnCu | 3.0517 |

| 22 | N | Aluminum - Wrought - Hardened | 3004 | 260% | 0 | 3004 | AlMn1Mg1 | 3.0526 |

| 22 | N | Aluminum - Wrought - Hardened | 5052 | 260% | 0 | 5052 | AlMg2,5 | 3.3523 |

| 22 | N | Aluminum - Wrought - Hardened | 5056 | 270% | 0 | 5056 | AlMg5 | 3.3555 |

| 22 | N | Aluminum - Wrought - Hardened | 6061 | 270% | 0 | 6061 | AlMgSiCu | 3.3211 |

| 22 | N | Aluminum - Wrought - Hardened | 6063 | 270% | 0 | 6063 | AlMgSi0,5 | 3.3206 |

| 22 | N | Aluminum - Wrought - Hardened | 7075 | 170% | 0 | 7075 | AlZnMgCu1,5 | 3.4365 |

| 26 | N | Copper Alloys | C36000 | 170% | 0 | C36000 | CuZn36Pb3 | 2.0375 |

| 31 | S | Iron (Fe) Based - Supper Alloys | 20CB-3 | 45% | 217 | ASTM B463 | ||

| 32 | S | Iron (Fe) Based - Supper Alloys | A-286 | 40% | 250 | ASTM 368 | X5NiCrTi2515 | 1.4980 |

| 32 | S | Iron (Fe) Based - Supper Alloys | Discaloy 16 | 40% | 290 | 5725 | ||

| 32 | S | Iron (Fe) Based - Supper Alloys | Discaloy 24 | 40% | 280 | ASTM A638 | ||

| 31 | S | Iron (Fe) Based - Supper Alloys | Incoloy 800 | 50% | 184 | ASME SB409 | X10NiCrAlTi3220 | |

| 31 | S | Iron (Fe) Based - Supper Alloys | Incoloy 801 | 50% | 180 | 5552 | G.X50CrNi3030 | 1.4868 |

| 31 | S | Iron (Fe) Based - Supper Alloys | Incoloy 802 | 50% | 180 | |||

| 31 | S | Iron (Fe) Based - Supper Alloys | Incoloy DS | 50% | 180 | X12NiCrSi3616 | ||

| 32 | S | Iron (Fe) Based - Supper Alloys | Marval 18 | 25% | 470 | |||

| 32 | S | Iron (Fe) Based - Supper Alloys | Udimet B-250 | 25% | 470 | |||

| 32 | S | Iron (Fe) Based - Supper Alloys | Udimet B-300 | 25% | 470 | |||

| 32 | S | Iron (Fe) Based - Supper Alloys | W-545 | 40% | 280 | AlSl:665 | ||

| 33 | S | Nickel (Ni) Based - Supper Alloys (20 HRC Max) | Hastelloy C-276 | 20% | 88 | G-NiMo30 | 2.4819 | |

| 33 | S | Nickel (Ni) Based - Supper Alloys (20 HRC Max) | Hastelloy X | 18% | 88 | 5536 | NiCr22FeMo | 2.4603 |

| 33 | S | Nickel (Ni) Based - Supper Alloys (20 HRC Max) | Monel 400 | 45% | 0 | 4544 | NiCu30Fe | 2.4360 |

| 33 | S | Nickel (Ni) Based - Supper Alloys (20 HRC Max) | Monel K500 | 35% | 0 | 4676 | NiCu30Al | 2.4375 |

| 33 | S | Nickel (Ni) Based - Supper Alloys (20 HRC Max) | Monel R405 | 45% | 0 | 4674 | ||

| 33 | S | Nickel (Ni) Based - Supper Alloys (20 HRC Max) | Nimonic 75 | 17% | 0 | NiCr20Ti | 2.4630 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Haynes 556 | 19% | 253 | 5768 | X12CrCoNi2120 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Haynes 625 | 17% | 274 | ASME SB443 | NiCr22Mo9Nb | 2.4856 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Haynes X-750 | 13% | 332 | 5542 | 2.4669 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Incoloy 903 | 11% | 379 | NiFe42K15Nb | ||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Incoloy 925 | 15% | 298 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 050 | 13% | 332 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 625 | 17% | 274 | ASME SB443.4 | NiCr22Mo9Nb | 2.4856 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 702 | 19% | 253 | 5550 | ||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 706 | 11% | 369 | AMS 5702 | ||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 718 | 10% | 389 | 5383 | NiCr19Fe19NbMo | 2.4668 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 718 DA | 9% | 405 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 718 OP | 12% | 350 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 718 Plus | 10% | 389 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 720 | 9% | 400 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 722 | 14% | 314 | 5541 | NiCr16FeTi | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 725 | 13% | 341 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel 783 | 14% | 314 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel MA754 | 17% | 274 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel X-750 | 15% | 298 | 5542 | NiCr16FeTi | 2.4669 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Inconel X-751 | 14% | 323 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | M-252 | 5% | 432 | 5551 | G-NiCr19Co | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | MP35N | 18% | 267 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Multimet N-155 | 18% | 260 | 5768 | 1.4971 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Multimet N-156 | 19% | 253 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Nimonic 105 | 14% | 314 | NiCo20Cr15MoAlTi | 2.4634 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Nimonic 80A | 12% | 350 | NiCr20TiAl | 2.4631 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Nimonic 90 | 10% | 267 | NiCr20Co18Ti | 2.4632 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Nimonic 901 | 13% | 332 | 5660, 5661 | NiCr15MoTi | 2.4662 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Nimonic C263 | 18% | 267 | NiCr20CoMoTi | 2.4650 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Nimonic PK33 | 12% | 350 | NiCr20Co16MoTi | ||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | René 41 | 15% | 332 | 5712, 5713 | NiCr19Co11MoTi | 2.4973 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | S 590 | 18% | 260 | 5533 | X40CoCrNi2020 | |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Udimet 520 | 11% | 369 | |||

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Udimet 718 | 10% | 389 | 5383 | NiCr19Fe19NbMo | 2.4668 |

| 34 | S | Nickel (Ni) Based - Supper Alloys (21-42 HRC) | Waspaloy® | 12% | 350 | 5544 | NiCr20Co14MoTi | 2.4654 |

| 35 | S | Cobalt (Co) Based - Supper Alloys | Stellite 151 | 6% | 432 | |||

| 35 | S | Cobalt (Co) Based - Supper Alloys | Stellite 21 | 17% | 332 | |||

| 35 | S | Cobalt (Co) Based - Supper Alloys | Stellite 25 (L605) | 12% | 350 | 5759 | CoCr20W15Ni | 2.4964 |

| 35 | S | Cobalt (Co) Based - Supper Alloys | Stellite 31 (X40) | 6% | 389 | ASTM A567 | CoCr25NiW | |

| 35 | S | Cobalt (Co) Based - Supper Alloys | Stellite 6 | 19% | 298 | |||

| 36 | S | Pure Titanium | Ti-99.5 (Grade 1) | 46% | 0 | Grade 1 B381F4 | Ti-99.5 | |

| 36 | S | Pure Titanium | Ti-99.6 (Grade 2) | 40% | 0 | Grade 2 B381F3 | Ti-99.6 | |

| 36 | S | Pure Titanium | Ti-99.7 (Grade 3) | 35% | 0 | Grade 3 B381F2 | Ti-99.7 | |

| 36 | S | Pure Titanium | Ti-99.8 (grade 4) | 28% | 0 | Grade 4 B381F1 | Ti-99.8 | |

| 37 | S | Titanium alloys | Ti-10.2.3 | 18% | 323 | |||

| 37 | S | Titanium alloys | Ti-13V-11Cr-3Al | 15% | 369 | 4917 | TiV13Cr11Al3 | |

| 37 | S | Titanium alloys | Ti-15-333 | 20% | 298 | |||

| 37 | S | Titanium alloys | Ti-15Mo (Alpha + Beta) | 16% | 350 | |||

| 37 | S | Titanium alloys | Ti-15Mo (Beta) | 28% | 240 | |||

| 37 | S | Titanium alloys | Ti-3Al-2.5V | 28% | 240 | 4943, 4944 | ||

| 37 | S | Titanium alloys | Ti-3Al-8V-6Cr-4Mo-4Zr | 20% | 298 | |||

| 37 | S | Titanium alloys | Ti-425 | 17% | 332 | |||

| 37 | S | Titanium alloys | Ti-425 MIL | 17% | 332 | |||

| 37 | S | Titanium alloys | Ti-48Al-2Cr-2Nb | 31% | 228 | |||

| 37 | S | Titanium alloys | Ti-4Al-4Mo-2Sn-0.5Si | 18% | 323 | TiAl4Mo4Sn2Si0.5 | ||

| 37 | S | Titanium alloys | Ti-5Al-2Sn-2Zr-4Cr-4Mo | 16% | 350 | 4995 | Ti5Al2Sn2Zr4Cr4Mo | |

| 37 | S | Titanium alloys | Ti-5Al-5Mo-5V-1Cr-1Fe | 15% | 369 | |||

| 37 | S | Titanium alloys | Ti-5Al-5V-5Mo-3Cr | 15% | 369 | |||

| 37 | S | Titanium alloys | Ti-6-2-4-6 | 17% | 332 | 4981 | ||

| 37 | S | Titanium alloys | Ti-6-7 | 20% | 298 | |||

| 37 | S | Titanium alloys | Ti-6Al-4V (Grade 5) | 20% | 298 | 4906, 4920, 4928, | TiAl6V4 | |

| 37 | S | Titanium alloys | Ti-6Al-4V ELI | 20% | 298 | 4907, 4930, 4931 | ||

| 37 | S | Titanium alloys | Ti-6Al-4V MIL | 17% | 341 | 4906, 4920, 4928, | TiAl6V4 | |

| 37 | S | Titanium alloys | Ti-6Al-4Zr-2Mo-2Sn | 24% | 267 | |||

| 37 | S | Titanium alloys | Ti-6Al-4Zr-2Mo-2Sn-0.2Si | 24% | 267 | 4919, 4975, 4976 | TiAl6Zr4Mo2Sn2 | |

| 37 | S | Titanium alloys | Ti-6Al-6V-2Sn | 18% | 323 | 4971 | TiAl16V6Sn2 | |

| 37 | S | Titanium alloys | Ti-8Al-1Mo-1V | 18% | 323 | 4915, 4933, 4972 | TiAl8Mo1V1 |

FAQ’S

What is machinability?

Machinability is the ease with which a metal can be machined. It is represented in percentage relative to a reference metal. A smaller value means the metal is harder to machine. Very difficult-to-machine materials can rate 10-20%, while very easy-to-machine materials can reach 200-400%

What are the factors affecting machinability?

1. Heat treatment.

2. Microstructure.

3. Grain size.

4. Hardness.

5. Fabrication quality

- Cutting Speed

- Cycle Time

- Steel

- Hardness

- Brinell scale

- Cutting Edge

- Machining Power

- Surface Finish

- CNC Machine

- ISO Material Groups in Machining

- Stainless Steel

- Carbon (c)

- Nickel (Ni)

- Ductility

- Toughness

- Hot Rolled

- Cold Working (Rolled/Drawn)

- Alloying elements for machining

- Chromium (Cr)

- Molybdenum (Mo

- Iron (Fe)

- Titanium (Ti)

- Grade

- Cast Iron

- Superalloys

- Rockwell scale

- Machinability

- Lead (Threading)