Table of Contents

List of Charts

* Easy access to all the data charts that appear on this page

- List of Symbols

- Designation Examples

- Possible Diameter/Pitch combinations.

- UNC Series – Basic Dimensions

- UNF Series – Basic Dimensions

- UNEF Series – Basic Dimensions

- Constant Pitch Series – Basic Dimensions

Overview

The Unified Thread Standard (UTS) defines a 60° thread form in Inch dimensions as described in the ASME B1.1 standard. It is the North American equivalent of the ISO metric thread system. The UTS serves as the leading standard for bolts, nuts, and a wide variety of other threaded fasteners used in the USA and Canada. However, in recent years the metric thread standard is becoming more common.

The standard defines diameter and pitch combinations along with allowances, tolerances, and designations. It has the same 60° profile as the ISO metric screw thread, but the basic dimensions of each UTS thread were chosen as an inch fraction rather than a millimeter value.

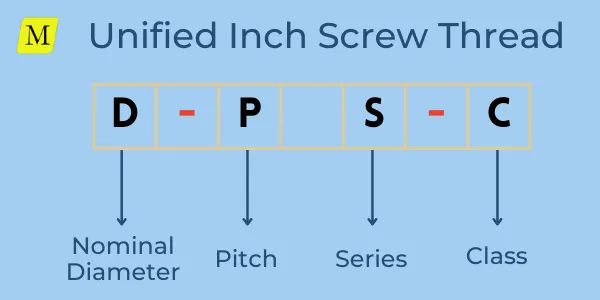

Designation

Basic designation syntax:

- Nominal Diameter in Inch Fraction

- Pitch in TPI

- Series: UNC / UNF / UNEF / UN

- Class: 1A, 2A, 3A, 1B, 2B or 3B.

Diameter:

- From 1/4″ and above the diameters are given in inch fractions. For example 1/4″, 3/4″, 1 1/4″.

- Below 1/4″ the diameters are given by a series of numbers from #0 to #12. Each “number” describes an arbitrary diameter as shown in the below table.

- It is also allowed to denote the diameters with a decimal value. For example 0.250 (1/4″), 0.4375 (7/16″), etc.

Standard Diameter numbers below 1/4″

|

Diameter

Number |

#0 | #1 | #2 | #3 | #4 | #5 | #6 | #8 | #10 | #12 |

|---|---|---|---|---|---|---|---|---|---|---|

|

Diameter

(Inch) |

0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 |

|

Diameter

(mm) |

1.524 | 1.8542 | 2.1844 | 2.5146 | 2.8448 | 3.175 | 3.5052 | 4.1656 | 4.8260 | 5.4864 |

Pitch:

- By default, the pitch is given in TPI. For example, 1/4-20 means a thread with a pitch of 20 TPI (1/20=0.05″).

- It is also allowed to denote the pitch by distance. For example, 1/4-0.05P means a thread with a pitch of 0.05″ (same as 20 TPI).

Series:

- In most cases, the series will be UNC, UNF, or UNEF (Coarse, Fine, or Extra fine pitch).

- ASTM B1.1, also defines several constant pitch series. These are denoted by ##-UN. For example, 12-UN or 8-UN. The pitch remains the same for the whole diameter range in these series. However, they are much less popular.

Class:

- The class is defined by a two-character code.

- The first character is a digit between 1 and 3. 3=Tight fit, 2=Medium fit, and 1=Loose fit.

- The second character is a letter. A=External thread and B=Internal thread.

- For a detailed explanation of classes, read the dedicated section below.

Additional Parameters:

- Direction: By default, the thread is right-hand. For a left-hand thread, add the suffix -LH.

- Number of Starts: By default, all threads have a single start. Thus the lead equals the pitch. For a multiple-start thread, the lead is also indicated. For example: 3/4– 0.0625P – 0.1875L UNF denotes a 3/4″ UNF thread with 3 starts. (0.1875/0.0625=3)

Designation Examples of Unified Threads

| Designation | Thread Series |

Internal /

External |

Nominal Diameter |

TPI | Pitch | Lead | Class | Number of Starts |

Thread Direction |

|---|---|---|---|---|---|---|---|---|---|

| #8-32 UNC | UNC | undefined | 0.164" | 32 | 0.03125" | 0.03125" | undefined | 1 | Right hand |

| 1/4 -28 UNF-2A | UNF | External | 0.25" | 28 | 0.0357" | 0.0357" | 2A | 1 | Right hand |

| 3/4-20 UNEF-3B | UNEF | Internal | 0.75" | 20 | 0.05" | 0.05" | 3B | 1 | Right hand |

| 1-12 UN-1A |

Constant Pitch

12 TPI |

External | 1" | 12 | 0.0833" | 0.0833" | 1A | 1 | Right hand |

| 3/4– 0.0625P – 0.1875L UNF-2A | UNF | External | 0.75" | 16 | 0.0625" | 0.1875" | 2A | 3 | Right hand |

| 1/4 -28 UNF-2A-LH | UNF | External | 0.25" | 28 | 0.0357" | 0.0357" | 2A | 1 | Left hand |

Possible Combinations (Diameter/Pitch)

The charts below show all the possible thread combinations that are defined in ASTM B1.1

- UNC– Unified Inch Coarse Thread Series

- UNF – Unified Inch Fine Thread Series

- UNEF – Unified Inch Extra Fine Thread Series

- ##-UN – Unified Inch Constant PitchThread Series

- Click to get the Full Thread Data-Sheet for a specific combination

Possible Combinations for 1/16″ – 1/4″

| Diameter | TPI=80 | 72 | 64 | 56 | 48 | 44 | 40 | 36 | 32 | 28 | 24 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.06 | UNF | |||||||||||

| 0.073 | UNF | UNC | ||||||||||

| 0.086 | UNF | UNC | ||||||||||

| 0.099 | UNF | UNC | ||||||||||

| 0.112 | UNF | UNC | ||||||||||

| 0.125 | UNF | UNC | ||||||||||

| 0.138 | UNF | UNC | ||||||||||

| 0.164 | UNF | UNC | ||||||||||

| 0.19 | UNF | UNC | ||||||||||

| 0.216 | UNEF | UNF | UNC | |||||||||

| 0.25 | UNEF | UNF | UNC |

Possible Combinations for 5/16″ – 1 1/2″

| Diameter | TPI=32 | 28 | 24 | 20 | 18 | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/16 | UNEF | 28-UN | UNF | 20-UN | UNC | ||||||||||

| 3/8 | UNEF | 28-UN | UNF | 20-UN | UNC | ||||||||||

| 7/16 | 32-UN | UNEF | UNF | 16-UN | UNC | ||||||||||

| 1/2 | 32-UN | UNEF | UNF | 16-UN | UNC | ||||||||||

| 9/16 | 32-UN | 28-UN | UNEF | 20-UN | UNF | 16-UN | UNC | ||||||||

| 5/8 | 32-UN | 28-UN | UNEF | 20-UN | UNF | 16-UN | 12-UN | UNC | |||||||

| 11/16 | 32-UN | 28-UN | UNEF | 20-UN | 16-UN | 12-UN | |||||||||

| 3/4 | 32-UN | 28-UN | UNEF | UNF | 12-UN | UNC | |||||||||

| 13/16 | 32-UN | 28-UN | UNEF | 16-UN | 12-UN | ||||||||||

| 7/8 | 32-UN | 28-UN | UNEF | 16-UN | UNF | 12-UN | UNC | ||||||||

| 15/16 | 32-UN | 28-UN | UNEF | 16-UN | 12-UN | ||||||||||

| 1 | 32-UN | 28-UN | UNEF | 16-UN | UNF | UNC | |||||||||

| 1 1/16 | 28-UN | 20-UN | UNEF | 16-UN | 12-UN | 8-UN | |||||||||

| 1 1/8 | 28-UN | 20-UN | UNEF | 16-UN | UNF | 8-UN | UNC | ||||||||

| 1 3/16 | 28-UN | 20-UN | UNEF | 16-UN | 12-UN | 8-UN | |||||||||

| 1 1/4 | 28-UN | 20-UN | UNEF | 16-UN | UNF | 8-UN | UNC | ||||||||

| 1 5/16 | 28-UN | 20-UN | UNEF | 16-UN | 12-UN | 8-UN | |||||||||

| 1 3/8 | 28-UN | 20-UN | UNEF | 16-UN | UNF | 8-UN | UNC | ||||||||

| 1 7/16 | 28-UN | 20-UN | UNEF | 16-UN | 12-UN | 8-UN | 6-UN | ||||||||

| 1 1/2 | 28-UN | 20-UN | UNEF | 16-UN | UNF | 8-UN | UNC |

Possible Combinations for 1 9/16″ – 6″

Basic Thread Dimensions (UNC, UNF & UNEF)

The basic dimensions are nominal dimensions of a unified thread profile without allowance and tolerances (The thread class defines that). They are based on standard ASTM B1.1. The basic dimensions can be used for design. However, for manufacturing and machining, you need the allowable range of each dimension. This data can be found in the standard or in the Limits and Dimensions section below. All the basic dimensions are derived from simple formulas based on the thread’s nominal diameter and pitch.

Symbols

List of symbols used in charts and formulas of Unified Inch Threads

| Symbol | Explanation |

|---|---|

| Basic Parameters - Diameters and Pitch | |

| D | Major (Basic) diameter of internal thread |

|

D1 |

Minor Diameter - Internal Thread |

| D2 | Pitch Diameter - Internal Thread |

| D3 | Major diameter, rounded root, internal thread |

| d | Major (Basic) diameter of external thread |

| d1 | Minor Diameter - External Thread |

| d2 | Pitch Diameter - External Thread |

| d3 | MMajor diameter, rounded root, internal thread |

| n | Number of threds per Inch (TPI) |

| P | Pitch (Distance) |

| L | Lead |

| Height Parameters | |

| H | Height of fundamental triangle |

| hs | Thread Height - External Thread |

| has | Thread addendum - External Thread |

| hn | Thread Height - Internal Thread |

| han | Thread addendum - Internal Thread |

| Length Parameters | |

| LE | Length of Engagment |

| Lts | Length - External Thread |

| Ltn | Length- Internal Thread |

| Allowance, Deviation, and Tolerances | |

| TD1 | Tolerance - D1 |

| TD2 | Tolerance - D2 |

| Td | Tolerance - d |

| Td2 | Tolerance - d2 |

| es | Allowance - External Thread |

| Crest / Root Parameters | |

| Fcs | Crest width - External Thread |

| Frs | Root width - External Thread |

| Fcs | Crest width - Internal Thread |

| Fcs | Root width - Internal Thread |

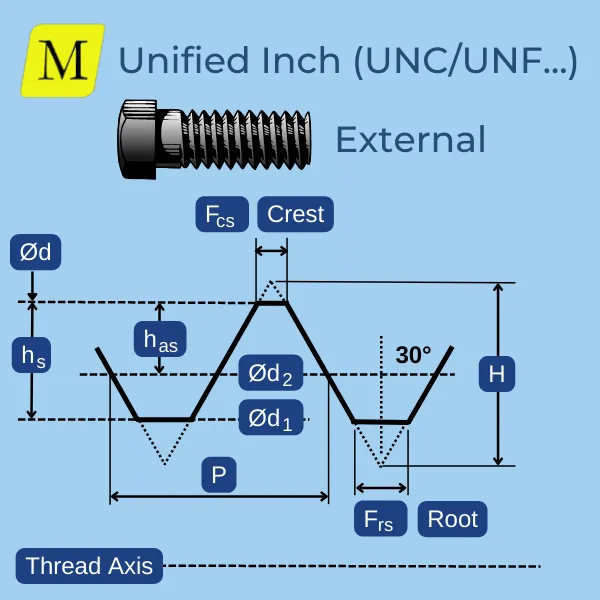

Formulas for basic dimensions

External Thread

\( \large P=\frac{1}{TPI} \)

\( \large H=\frac{\sqrt{3}}{2}\times{P} = 0.866025404\times{P} \)

\( \large h_s=\frac{5}{8}\times{H} \)

\( \large h_{as}=\frac{3}{8}\times{H}\)

\( \large d_2=d-{2}\times{h_{as}} \)

\( \large d_1=d-{2}\times{h_s}\)

\( \large F_{cs}=\frac{P}{8}\)

\( \large F_{rs}=\frac{P}{4}\)

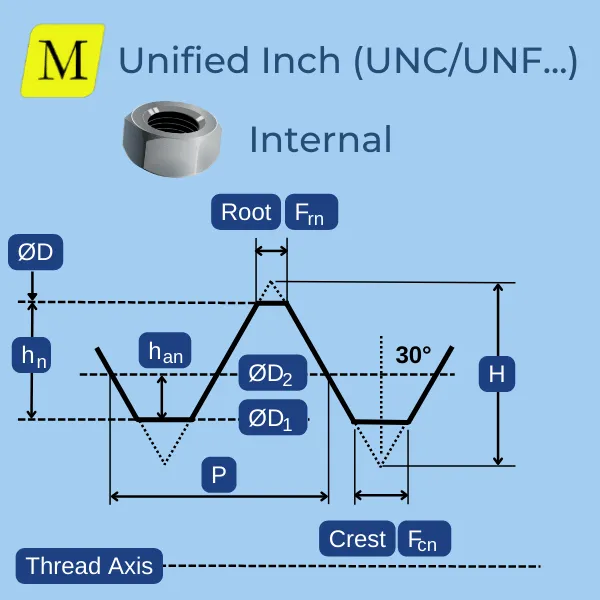

internal thread

\( \large P=\frac{1}{TPI} \)

\( \large H=\frac{\sqrt{3}}{2}\times{P} = 0.866025404\times{P} \)

\( \large h_n=\frac{5}{8}\times{H} \)

\( \large h_{an}=\frac{1}{4}\times{H}\)

\( \large D_1=D-{2}\times{h_n}\)

\( \large D_2=D1+{2}\times{h_{an}}\)

\( \large F_{rn}=\frac{P}{8}\)

\( \large F_{cn}=\frac{P}{4}\)

Unified Inch Threads Dimensions Charts

UNC Series Basic Dimensions chart

Click the Thread Link to get the Full Thread Data for all classes

All dimensions are in inches. To view the Metric translation, click the Thread Link

Click icon to show Additional columns

Click icon to show Full Thread Data

| Thread | Basic Diam | TPI | Pitch | Pitch Diam | Thread Height | Cres/ Root | Tap Drill Size | Lead Angle | Minor Diameter | Thread addendum | series | id | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #1 - 64 UNC | 0.073 | 64 | 0.0156 | 0.0629 | 0.0085 | 0.0039 | 0.0588 | 4.52° | 0.0544 | 0.0051 | UNC | 2 | ||

| #2 - 56 UNC | 0.086 | 56 | 0.0179 | 0.0744 | 0.0097 | 0.0045 | 0.0698 | 4.37° | 0.0647 | 0.0058 | UNC | 4 | ||

| #3 - 48 UNC | 0.099 | 48 | 0.0208 | 0.0855 | 0.0113 | 0.0052 | 0.08 | 4.44° | 0.0742 | 0.0068 | UNC | 6 | ||

| #4 - 40 UNC | 0.112 | 40 | 0.0250 | 0.0958 | 0.0135 | 0.0063 | 0.0893 | 4.75° | 0.0822 | 0.0081 | UNC | 8 | ||

| #5 - 40 UNC | 0.125 | 40 | 0.0250 | 0.1088 | 0.0135 | 0.0063 | 0.1023 | 4.18° | 0.0952 | 0.0081 | UNC | 10 | ||

| #6 - 32 UNC | 0.138 | 32 | 0.0313 | 0.1177 | 0.0169 | 0.0078 | 0.1096 | 4.83° | 0.1008 | 0.0101 | UNC | 12 | ||

| #8 - 32 UNC | 0.164 | 32 | 0.0313 | 0.1437 | 0.0169 | 0.0078 | 0.1356 | 3.96° | 0.1268 | 0.0101 | UNC | 15 | ||

| #10 - 24 UNC | 0.19 | 24 | 0.0417 | 0.1629 | 0.0226 | 0.0104 | 0.1521 | 4.65° | 0.1404 | 0.0135 | UNC | 18 | ||

| #12 - 24 UNC | 0.216 | 24 | 0.0417 | 0.1889 | 0.0226 | 0.0104 | 0.1781 | 4.02° | 0.1664 | 0.0135 | UNC | 21 | ||

| 1/4 - 20 UNC | 0.25 | 20 | 0.0500 | 0.2175 | 0.0271 | 0.0125 | 0.2045 | 4.18° | 0.1905 | 0.0162 | UNC | 26 | ||

| 5/16 - 18 UNC | 0.312 | 18 | 0.0556 | 0.2759 | 0.0301 | 0.0139 | 0.2614 | 3.67° | 0.2458 | 0.018 | UNC | 32 | ||

| 3/8 - 16 UNC | 0.375 | 16 | 0.0625 | 0.3344 | 0.0338 | 0.0156 | 0.3181 | 3.4° | 0.3006 | 0.0203 | UNC | 38 | ||

| 7/16 - 14 UNC | 0.437 | 14 | 0.0714 | 0.3906 | 0.0387 | 0.0179 | 0.372 | 3.33° | 0.3519 | 0.0232 | UNC | 45 | ||

| 1/2 - 13 UNC | 0.5 | 13 | 0.0769 | 0.45 | 0.0416 | 0.0192 | 0.43 | 3.11° | 0.4084 | 0.025 | UNC | 52 | ||

| 9/16 - 12 UNC | 0.562 | 12 | 0.0833 | 0.5079 | 0.0451 | 0.0208 | 0.4862 | 2.99° | 0.4628 | 0.0271 | UNC | 59 | ||

| 5/8 - 11 UNC | 0.625 | 11 | 0.0909 | 0.566 | 0.0492 | 0.0227 | 0.5423 | 2.93° | 0.5167 | 0.0295 | UNC | 67 | ||

| 3/4 - 10 UNC | 0.75 | 10 | 0.1000 | 0.685 | 0.0541 | 0.025 | 0.659 | 2.66° | 0.6309 | 0.0325 | UNC | 81 | ||

| 7/8 - 9 UNC | 0.875 | 9 | 0.1111 | 0.8028 | 0.0601 | 0.0278 | 0.7739 | 2.52° | 0.7427 | 0.0361 | UNC | 95 | ||

| 1 - 8 UNC | 1 | 8 | 0.1250 | 0.9188 | 0.0677 | 0.0313 | 0.8863 | 2.48° | 0.8512 | 0.0406 | UNC | 109 | ||

| 1 1/8 - 7 UNC | 1.125 | 7 | 0.1429 | 1.0322 | 0.0773 | 0.0357 | 0.995 | 2.52° | 0.9549 | 0.0464 | UNC | 124 | ||

| 1 1/4 - 7 UNC | 1.25 | 7 | 0.1429 | 1.1572 | 0.0773 | 0.0357 | 1.12 | 2.25° | 1.0799 | 0.0464 | UNC | 138 | ||

| 1 3/8 - 6 UNC | 1.375 | 6 | 0.1667 | 1.2667 | 0.0902 | 0.0417 | 1.2233 | 2.4° | 1.1765 | 0.0541 | UNC | 152 | ||

| 1 1/2 - 6 UNC | 1.5 | 6 | 0.1667 | 1.3917 | 0.0902 | 0.0417 | 1.3483 | 2.18° | 1.3015 | 0.0541 | UNC | 168 | ||

| 1 3/4 - 5 UNC | 1.75 | 5 | 0.2000 | 1.6201 | 0.1083 | 0.05 | 1.568 | 2.25° | 1.5118 | 0.065 | UNC | 195 | ||

| 2 - 4.5 UNC | 2 | 4 | 0.2222 | 1.8557 | 0.1203 | 0.0556 | 1.7978 | 2.18° | 1.7354 | 0.0722 | UNC | 216 | ||

| 2 1/4 - 4.5 UNC | 2.25 | 4 | 0.2222 | 2.1057 | 0.1203 | 0.0556 | 2.0478 | 1.92° | 1.9854 | 0.0722 | UNC | 227 | ||

| 2 1/2 - 4 UNC | 2.5 | 4 | 0.2500 | 2.3376 | 0.1353 | 0.0625 | 2.2725 | 1.95° | 2.2023 | 0.0812 | UNC | 238 | ||

| 2 3/4 - 4 UNC | 2.75 | 4 | 0.2500 | 2.5876 | 0.1353 | 0.0625 | 2.5225 | 1.76° | 2.4523 | 0.0812 | UNC | 251 | ||

| 3 - 4 UNC | 3 | 4 | 0.2500 | 2.8376 | 0.1353 | 0.0625 | 2.7725 | 1.61° | 2.7023 | 0.0812 | UNC | 264 | ||

| 3 1/4 - 4 UNC | 3.25 | 4 | 0.2500 | 3.0876 | 0.1353 | 0.0625 | 3.0225 | 1.48° | 2.9523 | 0.0812 | UNC | 276 | ||

| 3 1/2 - 4 UNC | 3.5 | 4 | 0.2500 | 3.3376 | 0.1353 | 0.0625 | 3.2725 | 1.37° | 3.2023 | 0.0812 | UNC | 287 | ||

| 3 3/4 - 4 UNC | 3.75 | 4 | 0.2500 | 3.5876 | 0.1353 | 0.0625 | 3.5225 | 1.27° | 3.4523 | 0.0812 | UNC | 298 | ||

| 4 - 4 UNC | 4 | 4 | 0.2500 | 3.8376 | 0.1353 | 0.0625 | 3.7725 | 1.19° | 3.7023 | 0.0812 | UNC | 309 |

UNF Series Basic Dimensions chart

Click the Thread Link to get the Full Thread Data for all classes

All dimensions are in inches. To view the Metric translation, click the Thread Link

Click icon to show Additional columns

Click icon to show Full Thread Data

| Thread | Basic Diam | TPI | Pitch | Pitch Diam | Thread Height | Cres/ Root | Tap Drill Size | Lead Angle | Minor Diameter | Thread addendum | series | id | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #0 - 80 UNF | 0.06 | 80 | 0.0125 | 0.0519 | 0.0068 | 0.0031 | 0.0486 | 4.39° | 0.0451 | 0.0041 | UNF | 1 | ||

| #1 - 72 UNF | 0.073 | 72 | 0.0139 | 0.064 | 0.0075 | 0.0035 | 0.0604 | 3.95° | 0.0565 | 0.0045 | UNF | 3 | ||

| #2 - 64 UNF | 0.086 | 64 | 0.0156 | 0.0759 | 0.0085 | 0.0039 | 0.0718 | 3.75° | 0.0674 | 0.0051 | UNF | 5 | ||

| #3 - 56 UNF | 0.099 | 56 | 0.0179 | 0.0874 | 0.0097 | 0.0045 | 0.0828 | 3.72° | 0.0777 | 0.0058 | UNF | 7 | ||

| #4 - 48 UNF | 0.112 | 48 | 0.0208 | 0.0985 | 0.0113 | 0.0052 | 0.093 | 3.85° | 0.0872 | 0.0068 | UNF | 9 | ||

| #5 - 44 UNF | 0.125 | 44 | 0.0227 | 0.1102 | 0.0123 | 0.0057 | 0.1043 | 3.75° | 0.0979 | 0.0074 | UNF | 11 | ||

| #6 - 40 UNF | 0.138 | 40 | 0.0250 | 0.1218 | 0.0135 | 0.0063 | 0.1153 | 3.74° | 0.1082 | 0.0081 | UNF | 13 | ||

| #8 - 36 UNF | 0.164 | 36 | 0.0278 | 0.146 | 0.015 | 0.0069 | 0.1387 | 3.47° | 0.1309 | 0.009 | UNF | 16 | ||

| #10 - 32 UNF | 0.19 | 32 | 0.0313 | 0.1697 | 0.0169 | 0.0078 | 0.1616 | 3.35° | 0.1528 | 0.0101 | UNF | 19 | ||

| #12 - 28 UNF | 0.216 | 28 | 0.0357 | 0.1928 | 0.0193 | 0.0089 | 0.1835 | 3.37° | 0.1735 | 0.0116 | UNF | 22 | ||

| 1/4 - 28 UNF | 0.25 | 28 | 0.0357 | 0.2268 | 0.0193 | 0.0089 | 0.2175 | 2.87° | 0.2075 | 0.0116 | UNF | 27 | ||

| 5/16 - 24 UNF | 0.312 | 24 | 0.0417 | 0.2849 | 0.0226 | 0.0104 | 0.2741 | 2.67° | 0.2624 | 0.0135 | UNF | 33 | ||

| 3/8 - 24 UNF | 0.375 | 24 | 0.0417 | 0.3479 | 0.0226 | 0.0104 | 0.3371 | 2.18° | 0.3254 | 0.0135 | UNF | 39 | ||

| 7/16 - 20 UNF | 0.437 | 20 | 0.0500 | 0.4045 | 0.0271 | 0.0125 | 0.3915 | 2.25° | 0.3775 | 0.0162 | UNF | 46 | ||

| 1/2 - 20 UNF | 0.5 | 20 | 0.0500 | 0.4675 | 0.0271 | 0.0125 | 0.4545 | 1.95° | 0.4405 | 0.0162 | UNF | 53 | ||

| 9/16 - 18 UNF | 0.562 | 18 | 0.0556 | 0.5259 | 0.0301 | 0.0139 | 0.5114 | 1.93° | 0.4958 | 0.018 | UNF | 60 | ||

| 5/8 - 18 UNF | 0.625 | 18 | 0.0556 | 0.5889 | 0.0301 | 0.0139 | 0.5744 | 1.72° | 0.5588 | 0.018 | UNF | 68 | ||

| 3/4 - 16 UNF | 0.75 | 16 | 0.0625 | 0.7094 | 0.0338 | 0.0156 | 0.6931 | 1.61° | 0.6756 | 0.0203 | UNF | 82 | ||

| 7/8 - 14 UNF | 0.875 | 14 | 0.0714 | 0.8286 | 0.0387 | 0.0179 | 0.81 | 1.57° | 0.7899 | 0.0232 | UNF | 96 | ||

| 1 - 12 UNF | 1 | 12 | 0.0833 | 0.9459 | 0.0451 | 0.0208 | 0.9242 | 1.61° | 0.9008 | 0.0271 | UNF | 110 | ||

| 1 1/8 - 12 UNF | 1.125 | 12 | 0.0833 | 1.0709 | 0.0451 | 0.0208 | 1.0492 | 1.42° | 1.0258 | 0.0271 | UNF | 125 | ||

| 1 1/4 - 12 UNF | 1.25 | 12 | 0.0833 | 1.1959 | 0.0451 | 0.0208 | 1.1742 | 1.27° | 1.1508 | 0.0271 | UNF | 139 | ||

| 1 3/8 - 12 UNF | 1.375 | 12 | 0.0833 | 1.3209 | 0.0451 | 0.0208 | 1.2992 | 1.15° | 1.2758 | 0.0271 | UNF | 153 | ||

| 1 1/2 - 12 UNF | 1.5 | 12 | 0.0833 | 1.4459 | 0.0451 | 0.0208 | 1.4242 | 1.05° | 1.4008 | 0.0271 | UNF | 169 |

UNEF Series Basic Dimensions chart

Click the Thread Link to get the Full Thread Data for all classes

All dimensions are in inches. To view the Metric translation, click the Thread Link

Click icon to show Additional columns

Click icon to show Full Thread Data

| Thread | Basic Diam | TPI | Pitch | Pitch Diam | Thread Height | Cres/ Root | Tap Drill Size | Lead Angle | Minor Diameter | Thread addendum | series | id | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #12 - 32 UNEF | 0.216 | 32 | 0.0313 | 0.1957 | 0.0169 | 0.0078 | 0.1876 | 2.91° | 0.1788 | 0.0101 | UNEF | 23 | ||

| 1/4 - 32 UNEF | 0.25 | 32 | 0.0313 | 0.2297 | 0.0169 | 0.0078 | 0.2216 | 2.48° | 0.2128 | 0.0101 | UNEF | 28 | ||

| 5/16 - 32 UNEF | 0.312 | 32 | 0.0313 | 0.2917 | 0.0169 | 0.0078 | 0.2836 | 1.95° | 0.2748 | 0.0101 | UNEF | 34 | ||

| 3/8 - 32 UNEF | 0.375 | 32 | 0.0313 | 0.3547 | 0.0169 | 0.0078 | 0.3466 | 1.61° | 0.3378 | 0.0101 | UNEF | 40 | ||

| 7/16 - 28 UNEF | 0.437 | 28 | 0.0357 | 0.4138 | 0.0193 | 0.0089 | 0.4045 | 1.57° | 0.3945 | 0.0116 | UNEF | 47 | ||

| 1/2 - 28 UNEF | 0.5 | 28 | 0.0357 | 0.4768 | 0.0193 | 0.0089 | 0.4675 | 1.37° | 0.4575 | 0.0116 | UNEF | 54 | ||

| 9/16 - 24 UNEF | 0.562 | 24 | 0.0417 | 0.5349 | 0.0226 | 0.0104 | 0.5241 | 1.42° | 0.5124 | 0.0135 | UNEF | 61 | ||

| 5/8 - 24 UNEF | 0.625 | 24 | 0.0417 | 0.5979 | 0.0226 | 0.0104 | 0.5871 | 1.27° | 0.5754 | 0.0135 | UNEF | 69 | ||

| 11/16 - 24 UNEF | 0.687 | 24 | 0.0417 | 0.6599 | 0.0226 | 0.0104 | 0.6491 | 1.15° | 0.6374 | 0.0135 | UNEF | 75 | ||

| 3/4 - 20 UNEF | 0.75 | 20 | 0.0500 | 0.7175 | 0.0271 | 0.0125 | 0.7045 | 1.27° | 0.6905 | 0.0162 | UNEF | 83 | ||

| 13/16 - 20 UNEF | 0.812 | 20 | 0.0500 | 0.7795 | 0.0271 | 0.0125 | 0.7665 | 1.17° | 0.7525 | 0.0162 | UNEF | 89 | ||

| 7/8 - 20 UNEF | 0.875 | 20 | 0.0500 | 0.8425 | 0.0271 | 0.0125 | 0.8295 | 1.08° | 0.8155 | 0.0162 | UNEF | 97 | ||

| 15/16 - 20 UNEF | 0.937 | 20 | 0.0500 | 0.9045 | 0.0271 | 0.0125 | 0.8915 | 1.01° | 0.8775 | 0.0162 | UNEF | 103 | ||

| 1 - 20 UNEF | 1 | 20 | 0.0500 | 0.9675 | 0.0271 | 0.0125 | 0.9545 | 0.94° | 0.9405 | 0.0162 | UNEF | 111 | ||

| 1 1/16 - 18 UNEF | 1.062 | 18 | 0.0556 | 1.0259 | 0.0301 | 0.0139 | 1.0114 | 0.99° | 0.9958 | 0.018 | UNEF | 118 | ||

| 1 1/8 - 18 UNEF | 1.125 | 18 | 0.0556 | 1.0889 | 0.0301 | 0.0139 | 1.0744 | 0.93° | 1.0588 | 0.018 | UNEF | 126 | ||

| 1 3/16 - 18 UNEF | 1.187 | 18 | 0.0556 | 1.1509 | 0.0301 | 0.0139 | 1.1364 | 0.88° | 1.1208 | 0.018 | UNEF | 132 | ||

| 1 1/4 - 18 UNEF | 1.25 | 18 | 0.0556 | 1.2139 | 0.0301 | 0.0139 | 1.1994 | 0.83° | 1.1838 | 0.018 | UNEF | 140 | ||

| 1 5/16 - 18 UNEF | 1.312 | 18 | 0.0556 | 1.2759 | 0.0301 | 0.0139 | 1.2614 | 0.79° | 1.2458 | 0.018 | UNEF | 146 | ||

| 1 3/8 - 18 UNEF | 1.375 | 18 | 0.0556 | 1.3389 | 0.0301 | 0.0139 | 1.3244 | 0.76° | 1.3088 | 0.018 | UNEF | 154 | ||

| 1 7/16 - 18 UNEF | 1.437 | 18 | 0.0556 | 1.4009 | 0.0301 | 0.0139 | 1.3864 | 0.72° | 1.3708 | 0.018 | UNEF | 161 | ||

| 1 1/2 - 18 UNEF | 1.5 | 18 | 0.0556 | 1.4639 | 0.0301 | 0.0139 | 1.4494 | 0.69° | 1.4338 | 0.018 | UNEF | 170 | ||

| 1 9/16 - 18 UNEF | 1.562 | 18 | 0.0556 | 1.5259 | 0.0301 | 0.0139 | 1.5114 | 0.66° | 1.4958 | 0.018 | UNEF | 177 | ||

| 1 5/8 - 18 UNEF | 1.625 | 18 | 0.0556 | 1.5889 | 0.0301 | 0.0139 | 1.5744 | 0.64° | 1.5588 | 0.018 | UNEF | 183 | ||

| 1 11/16 - 18 UNEF | 1.687 | 18 | 0.0556 | 1.6509 | 0.0301 | 0.0139 | 1.6364 | 0.61° | 1.6208 | 0.018 | UNEF | 189 |

UN Constant Pitch Series Basic Dimensions chart

Click the Thread Link to get the Full Thread Data for all classes

All dimensions are in inches. To view the Metric translation, click the Thread Link

Click icon to show Additional columns

Click icon to show Full Thread Data

| Thread | Basic Diam | TPI | Pitch | Pitch Diam | Thread Height | Cres/ Root | Tap Drill Size | Lead Angle | Minor Diameter | Thread addendum | series | id | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16 - 12 12-UN | 0.562 | 12 | 0.0833 | 0.5079 | 0.0451 | 0.0208 | 0.4862 | 2.99° | 0.4628 | 0.0271 | 12-UN | 62 | ||

| 5/8 - 12 12-UN | 0.625 | 12 | 0.0833 | 0.5709 | 0.0451 | 0.0208 | 0.5492 | 2.66° | 0.5258 | 0.0271 | 12-UN | 70 | ||

| 11/16 - 12 12-UN | 0.687 | 12 | 0.0833 | 0.6329 | 0.0451 | 0.0208 | 0.6112 | 2.4° | 0.5878 | 0.0271 | 12-UN | 76 | ||

| 3/4 - 12 12-UN | 0.75 | 12 | 0.0833 | 0.6959 | 0.0451 | 0.0208 | 0.6742 | 2.18° | 0.6508 | 0.0271 | 12-UN | 84 | ||

| 13/16 - 12 12-UN | 0.812 | 12 | 0.0833 | 0.7579 | 0.0451 | 0.0208 | 0.7362 | 2° | 0.7128 | 0.0271 | 12-UN | 90 | ||

| 7/8 - 12 12-UN | 0.875 | 12 | 0.0833 | 0.8209 | 0.0451 | 0.0208 | 0.7992 | 1.85° | 0.7758 | 0.0271 | 12-UN | 98 | ||

| 15/16 - 12 12-UN | 0.937 | 12 | 0.0833 | 0.8829 | 0.0451 | 0.0208 | 0.8612 | 1.72° | 0.8378 | 0.0271 | 12-UN | 104 | ||

| 1 - 12 12-UN | 1 | 12 | 0.0833 | 0.9459 | 0.0451 | 0.0208 | 0.9242 | 1.61° | 0.9008 | 0.0271 | 12-UN | 113 | ||

| 1 1/16 - 12 12-UN | 1.062 | 12 | 0.0833 | 1.0079 | 0.0451 | 0.0208 | 0.9862 | 1.51° | 0.9628 | 0.0271 | 12-UN | 120 | ||

| 1 1/8 - 12 12-UN | 1.125 | 12 | 0.0833 | 1.0709 | 0.0451 | 0.0208 | 1.0492 | 1.42° | 1.0258 | 0.0271 | 12-UN | 128 | ||

| 1 3/16 - 12 12-UN | 1.187 | 12 | 0.0833 | 1.1329 | 0.0451 | 0.0208 | 1.1112 | 1.34° | 1.0878 | 0.0271 | 12-UN | 134 | ||

| 1 1/4 - 12 12-UN | 1.25 | 12 | 0.0833 | 1.1959 | 0.0451 | 0.0208 | 1.1742 | 1.27° | 1.1508 | 0.0271 | 12-UN | 142 | ||

| 1 5/16 - 12 12-UN | 1.312 | 12 | 0.0833 | 1.2579 | 0.0451 | 0.0208 | 1.2362 | 1.21° | 1.2128 | 0.0271 | 12-UN | 148 | ||

| 1 3/8 - 12 12-UN | 1.375 | 12 | 0.0833 | 1.3209 | 0.0451 | 0.0208 | 1.2992 | 1.15° | 1.2758 | 0.0271 | 12-UN | 157 | ||

| 1 7/16 - 12 12-UN | 1.437 | 12 | 0.0833 | 1.3829 | 0.0451 | 0.0208 | 1.3612 | 1.1° | 1.3378 | 0.0271 | 12-UN | 164 | ||

| 1 1/2 - 12 12-UN | 1.5 | 12 | 0.0833 | 1.4459 | 0.0451 | 0.0208 | 1.4242 | 1.05° | 1.4008 | 0.0271 | 12-UN | 173 | ||

| 1 9/16 - 12 12-UN | 1.562 | 12 | 0.0833 | 1.5079 | 0.0451 | 0.0208 | 1.4862 | 1.01° | 1.4628 | 0.0271 | 12-UN | 180 | ||

| 1 5/8 - 12 12-UN | 1.625 | 12 | 0.0833 | 1.5709 | 0.0451 | 0.0208 | 1.5492 | 0.97° | 1.5258 | 0.0271 | 12-UN | 186 | ||

| 1 11/16 - 12 12-UN | 1.687 | 12 | 0.0833 | 1.6329 | 0.0451 | 0.0208 | 1.6112 | 0.93° | 1.5878 | 0.0271 | 12-UN | 192 | ||

| 1 3/4 - 12 12-UN | 1.75 | 12 | 0.0833 | 1.6959 | 0.0451 | 0.0208 | 1.6742 | 0.9° | 1.6508 | 0.0271 | 12-UN | 198 | ||

| 1 13/16 - 12 12-UN | 1.812 | 12 | 0.0833 | 1.7579 | 0.0451 | 0.0208 | 1.7362 | 0.86° | 1.7128 | 0.0271 | 12-UN | 203 | ||

| 1 7/8 - 12 12-UN | 1.875 | 12 | 0.0833 | 1.8209 | 0.0451 | 0.0208 | 1.7992 | 0.83° | 1.7758 | 0.0271 | 12-UN | 208 | ||

| 1 15/16 - 12 12-UN | 1.937 | 12 | 0.0833 | 1.8829 | 0.0451 | 0.0208 | 1.8612 | 0.81° | 1.8378 | 0.0271 | 12-UN | 213 | ||

| 2 - 12 12-UN | 2 | 12 | 0.0833 | 1.9459 | 0.0451 | 0.0208 | 1.9242 | 0.78° | 1.9008 | 0.0271 | 12-UN | 219 | ||

| 2 1/8 - 12 12-UN | 2.125 | 12 | 0.0833 | 2.0709 | 0.0451 | 0.0208 | 2.0492 | 0.73° | 2.0258 | 0.0271 | 12-UN | 224 | ||

| 2 1/4 - 12 12-UN | 2.25 | 12 | 0.0833 | 2.1959 | 0.0451 | 0.0208 | 2.1742 | 0.69° | 2.1508 | 0.0271 | 12-UN | 230 | ||

| 2 3/8 - 12 12-UN | 2.375 | 12 | 0.0833 | 2.3209 | 0.0451 | 0.0208 | 2.2992 | 0.65° | 2.2758 | 0.0271 | 12-UN | 235 | ||

| 2 1/2 - 12 12-UN | 2.5 | 12 | 0.0833 | 2.4459 | 0.0451 | 0.0208 | 2.4242 | 0.62° | 2.4008 | 0.0271 | 12-UN | 242 | ||

| 2 5/8 - 12 12-UN | 2.625 | 12 | 0.0833 | 2.5709 | 0.0451 | 0.0208 | 2.5492 | 0.59° | 2.5258 | 0.0271 | 12-UN | 248 | ||

| 2 3/4 - 12 12-UN | 2.75 | 12 | 0.0833 | 2.6959 | 0.0451 | 0.0208 | 2.6742 | 0.56° | 2.6508 | 0.0271 | 12-UN | 255 | ||

| 2 7/8 - 12 12-UN | 2.875 | 12 | 0.0833 | 2.8209 | 0.0451 | 0.0208 | 2.7992 | 0.54° | 2.7758 | 0.0271 | 12-UN | 261 | ||

| 3 - 12 12-UN | 3 | 12 | 0.0833 | 2.9459 | 0.0451 | 0.0208 | 2.9242 | 0.52° | 2.9008 | 0.0271 | 12-UN | 268 | ||

| 3 1/8 - 12 12-UN | 3.125 | 12 | 0.0833 | 3.0709 | 0.0451 | 0.0208 | 3.0492 | 0.49° | 3.0258 | 0.0271 | 12-UN | 274 | ||

| 3 1/4 - 12 12-UN | 3.25 | 12 | 0.0833 | 3.1959 | 0.0451 | 0.0208 | 3.1742 | 0.48° | 3.1508 | 0.0271 | 12-UN | 280 | ||

| 3 3/8 - 12 12-UN | 3.375 | 12 | 0.0833 | 3.3209 | 0.0451 | 0.0208 | 3.2992 | 0.46° | 3.2758 | 0.0271 | 12-UN | 285 | ||

| 3 1/2 - 12 12-UN | 3.5 | 12 | 0.0833 | 3.4459 | 0.0451 | 0.0208 | 3.4242 | 0.44° | 3.4008 | 0.0271 | 12-UN | 291 | ||

| 3 5/8 - 12 12-UN | 3.625 | 12 | 0.0833 | 3.5709 | 0.0451 | 0.0208 | 3.5492 | 0.43° | 3.5258 | 0.0271 | 12-UN | 296 | ||

| 3 3/4 - 12 12-UN | 3.75 | 12 | 0.0833 | 3.6959 | 0.0451 | 0.0208 | 3.6742 | 0.41° | 3.6508 | 0.0271 | 12-UN | 302 | ||

| 3 7/8 - 12 12-UN | 3.875 | 12 | 0.0833 | 3.8209 | 0.0451 | 0.0208 | 3.7992 | 0.4° | 3.7758 | 0.0271 | 12-UN | 307 | ||

| 4 - 12 12-UN | 4 | 12 | 0.0833 | 3.9459 | 0.0451 | 0.0208 | 3.9242 | 0.39° | 3.9008 | 0.0271 | 12-UN | 313 | ||

| 4 1/8 - 12 12-UN | 4.125 | 12 | 0.0833 | 4.0709 | 0.0451 | 0.0208 | 4.0492 | 0.37° | 4.0258 | 0.0271 | 12-UN | 318 | ||

| 4 1/4 - 12 12-UN | 4.25 | 12 | 0.0833 | 4.1959 | 0.0451 | 0.0208 | 4.1742 | 0.36° | 4.1508 | 0.0271 | 12-UN | 323 | ||

| 4 3/8 - 12 12-UN | 4.375 | 12 | 0.0833 | 4.3209 | 0.0451 | 0.0208 | 4.2992 | 0.35° | 4.2758 | 0.0271 | 12-UN | 328 | ||

| 4 1/2 - 12 12-UN | 4.5 | 12 | 0.0833 | 4.4459 | 0.0451 | 0.0208 | 4.4242 | 0.34° | 4.4008 | 0.0271 | 12-UN | 333 | ||

| 4 5/8 - 12 12-UN | 4.625 | 12 | 0.0833 | 4.5709 | 0.0451 | 0.0208 | 4.5492 | 0.33° | 4.5258 | 0.0271 | 12-UN | 338 | ||

| 4 3/4 - 12 12-UN | 4.75 | 12 | 0.0833 | 4.6959 | 0.0451 | 0.0208 | 4.6742 | 0.32° | 4.6508 | 0.0271 | 12-UN | 344 | ||

| 4 7/8 - 12 12-UN | 4.875 | 12 | 0.0833 | 4.8209 | 0.0451 | 0.0208 | 4.7992 | 0.32° | 4.7758 | 0.0271 | 12-UN | 349 | ||

| 5 - 12 12-UN | 5 | 12 | 0.0833 | 4.9459 | 0.0451 | 0.0208 | 4.9242 | 0.31° | 4.9008 | 0.0271 | 12-UN | 354 | ||

| 5 1/8 - 12 12-UN | 5.125 | 12 | 0.0833 | 5.0709 | 0.0451 | 0.0208 | 5.0492 | 0.3° | 5.0258 | 0.0271 | 12-UN | 359 | ||

| 5 1/4 - 12 12-UN | 5.25 | 12 | 0.0833 | 5.1959 | 0.0451 | 0.0208 | 5.1742 | 0.29° | 5.1508 | 0.0271 | 12-UN | 364 | ||

| 5 3/8 - 12 12-UN | 5.375 | 12 | 0.0833 | 5.3209 | 0.0451 | 0.0208 | 5.2992 | 0.29° | 5.2758 | 0.0271 | 12-UN | 369 | ||

| 5 1/2 - 12 12-UN | 5.5 | 12 | 0.0833 | 5.4459 | 0.0451 | 0.0208 | 5.4242 | 0.28° | 5.4008 | 0.0271 | 12-UN | 374 | ||

| 5 5/8 - 12 12-UN | 5.625 | 12 | 0.0833 | 5.5709 | 0.0451 | 0.0208 | 5.5492 | 0.27° | 5.5258 | 0.0271 | 12-UN | 379 | ||

| 5 3/4 - 12 12-UN | 5.75 | 12 | 0.0833 | 5.6959 | 0.0451 | 0.0208 | 5.6742 | 0.27° | 5.6508 | 0.0271 | 12-UN | 384 | ||

| 5 7/8 - 12 12-UN | 5.875 | 12 | 0.0833 | 5.8209 | 0.0451 | 0.0208 | 5.7992 | 0.26° | 5.7758 | 0.0271 | 12-UN | 389 | ||

| 6 - 12 12-UN | 6 | 12 | 0.0833 | 5.9459 | 0.0451 | 0.0208 | 5.9242 | 0.26° | 5.9008 | 0.0271 | 12-UN | 394 | ||

| 3/8 - 16 16-UN | 0.375 | 16 | 0.0625 | 0.3344 | 0.0338 | 0.0156 | 0.3181 | 3.4° | 0.3006 | 0.0203 | 16-UN | 41 | ||

| 7/16 - 16 16-UN | 0.437 | 16 | 0.0625 | 0.3964 | 0.0338 | 0.0156 | 0.3801 | 2.87° | 0.3626 | 0.0203 | 16-UN | 48 | ||

| 1/2 - 16 16-UN | 0.5 | 16 | 0.0625 | 0.4594 | 0.0338 | 0.0156 | 0.4431 | 2.48° | 0.4256 | 0.0203 | 16-UN | 55 | ||

| 9/16 - 16 16-UN | 0.562 | 16 | 0.0625 | 0.5214 | 0.0338 | 0.0156 | 0.5051 | 2.19° | 0.4876 | 0.0203 | 16-UN | 63 | ||

| 5/8 - 16 16-UN | 0.625 | 16 | 0.0625 | 0.5844 | 0.0338 | 0.0156 | 0.5681 | 1.95° | 0.5506 | 0.0203 | 16-UN | 71 | ||

| 11/16 - 16 16-UN | 0.687 | 16 | 0.0625 | 0.6464 | 0.0338 | 0.0156 | 0.6301 | 1.76° | 0.6126 | 0.0203 | 16-UN | 77 | ||

| 3/4 - 16 16-UN | 0.75 | 16 | 0.0625 | 0.7094 | 0.0338 | 0.0156 | 0.6931 | 1.61° | 0.6756 | 0.0203 | 16-UN | 85 | ||

| 13/16 - 16 16-UN | 0.812 | 16 | 0.0625 | 0.7714 | 0.0338 | 0.0156 | 0.7551 | 1.48° | 0.7376 | 0.0203 | 16-UN | 91 | ||

| 7/8 - 16 16-UN | 0.875 | 16 | 0.0625 | 0.8344 | 0.0338 | 0.0156 | 0.8181 | 1.37° | 0.8006 | 0.0203 | 16-UN | 99 | ||

| 15/16 - 16 16-UN | 0.937 | 16 | 0.0625 | 0.8964 | 0.0338 | 0.0156 | 0.8801 | 1.27° | 0.8626 | 0.0203 | 16-UN | 105 | ||

| 1 - 16 16-UN | 1 | 16 | 0.0625 | 0.9594 | 0.0338 | 0.0156 | 0.9431 | 1.19° | 0.9256 | 0.0203 | 16-UN | 114 | ||

| 1 1/16 - 16 16-UN | 1.062 | 16 | 0.0625 | 1.0214 | 0.0338 | 0.0156 | 1.0051 | 1.12° | 0.9876 | 0.0203 | 16-UN | 121 | ||

| 1 1/8 - 16 16-UN | 1.125 | 16 | 0.0625 | 1.0844 | 0.0338 | 0.0156 | 1.0681 | 1.05° | 1.0506 | 0.0203 | 16-UN | 129 | ||

| 1 3/16 - 16 16-UN | 1.187 | 16 | 0.0625 | 1.1464 | 0.0338 | 0.0156 | 1.1301 | 0.99° | 1.1126 | 0.0203 | 16-UN | 135 | ||

| 1 1/4 - 16 16-UN | 1.25 | 16 | 0.0625 | 1.2094 | 0.0338 | 0.0156 | 1.1931 | 0.94° | 1.1756 | 0.0203 | 16-UN | 143 | ||

| 1 5/16 - 16 16-UN | 1.312 | 16 | 0.0625 | 1.2714 | 0.0338 | 0.0156 | 1.2551 | 0.9° | 1.2376 | 0.0203 | 16-UN | 149 | ||

| 1 3/8 - 16 16-UN | 1.375 | 16 | 0.0625 | 1.3344 | 0.0338 | 0.0156 | 1.3181 | 0.85° | 1.3006 | 0.0203 | 16-UN | 158 | ||

| 1 7/16 - 16 16-UN | 1.437 | 16 | 0.0625 | 1.3964 | 0.0338 | 0.0156 | 1.3801 | 0.82° | 1.3626 | 0.0203 | 16-UN | 165 | ||

| 1 1/2 - 16 16-UN | 1.5 | 16 | 0.0625 | 1.4594 | 0.0338 | 0.0156 | 1.4431 | 0.78° | 1.4256 | 0.0203 | 16-UN | 174 | ||

| 1 9/16 - 16 16-UN | 1.562 | 16 | 0.0625 | 1.5214 | 0.0338 | 0.0156 | 1.5051 | 0.75° | 1.4876 | 0.0203 | 16-UN | 181 | ||

| 1 5/8 - 16 16-UN | 1.625 | 16 | 0.0625 | 1.5844 | 0.0338 | 0.0156 | 1.5681 | 0.72° | 1.5506 | 0.0203 | 16-UN | 187 | ||

| 1 11/16 - 16 16-UN | 1.687 | 16 | 0.0625 | 1.6464 | 0.0338 | 0.0156 | 1.6301 | 0.69° | 1.6126 | 0.0203 | 16-UN | 193 | ||

| 1 3/4 - 16 16-UN | 1.75 | 16 | 0.0625 | 1.7094 | 0.0338 | 0.0156 | 1.6931 | 0.67° | 1.6756 | 0.0203 | 16-UN | 199 | ||

| 1 13/16 - 16 16-UN | 1.812 | 16 | 0.0625 | 1.7714 | 0.0338 | 0.0156 | 1.7551 | 0.64° | 1.7376 | 0.0203 | 16-UN | 204 | ||

| 1 7/8 - 16 16-UN | 1.875 | 16 | 0.0625 | 1.8344 | 0.0338 | 0.0156 | 1.8181 | 0.62° | 1.8006 | 0.0203 | 16-UN | 209 | ||

| 1 15/16 - 16 16-UN | 1.937 | 16 | 0.0625 | 1.8964 | 0.0338 | 0.0156 | 1.8801 | 0.6° | 1.8626 | 0.0203 | 16-UN | 214 | ||

| 2 - 16 16-UN | 2 | 16 | 0.0625 | 1.9594 | 0.0338 | 0.0156 | 1.9431 | 0.58° | 1.9256 | 0.0203 | 16-UN | 220 | ||

| 2 1/8 - 16 16-UN | 2.125 | 16 | 0.0625 | 2.0844 | 0.0338 | 0.0156 | 2.0681 | 0.55° | 2.0506 | 0.0203 | 16-UN | 225 | ||

| 2 1/4 - 16 16-UN | 2.25 | 16 | 0.0625 | 2.2094 | 0.0338 | 0.0156 | 2.1931 | 0.52° | 2.1756 | 0.0203 | 16-UN | 231 | ||

| 2 3/8 - 16 16-UN | 2.375 | 16 | 0.0625 | 2.3344 | 0.0338 | 0.0156 | 2.3181 | 0.49° | 2.3006 | 0.0203 | 16-UN | 236 | ||

| 2 1/2 - 16 16-UN | 2.5 | 16 | 0.0625 | 2.4594 | 0.0338 | 0.0156 | 2.4431 | 0.46° | 2.4256 | 0.0203 | 16-UN | 243 | ||

| 2 5/8 - 16 16-UN | 2.625 | 16 | 0.0625 | 2.5844 | 0.0338 | 0.0156 | 2.5681 | 0.44° | 2.5506 | 0.0203 | 16-UN | 249 | ||

| 2 3/4 - 16 16-UN | 2.75 | 16 | 0.0625 | 2.7094 | 0.0338 | 0.0156 | 2.6931 | 0.42° | 2.6756 | 0.0203 | 16-UN | 256 | ||

| 2 7/8 - 16 16-UN | 2.875 | 16 | 0.0625 | 2.8344 | 0.0338 | 0.0156 | 2.8181 | 0.4° | 2.8006 | 0.0203 | 16-UN | 262 | ||

| 3 - 16 16-UN | 3 | 16 | 0.0625 | 2.9594 | 0.0338 | 0.0156 | 2.9431 | 0.39° | 2.9256 | 0.0203 | 16-UN | 269 | ||

| 3 1/8 - 16 16-UN | 3.125 | 16 | 0.0625 | 3.0844 | 0.0338 | 0.0156 | 3.0681 | 0.37° | 3.0506 | 0.0203 | 16-UN | 275 | ||

| 3 1/4 - 16 16-UN | 3.25 | 16 | 0.0625 | 3.2094 | 0.0338 | 0.0156 | 3.1931 | 0.36° | 3.1756 | 0.0203 | 16-UN | 281 | ||

| 3 3/8 - 16 16-UN | 3.375 | 16 | 0.0625 | 3.3344 | 0.0338 | 0.0156 | 3.3181 | 0.34° | 3.3006 | 0.0203 | 16-UN | 286 | ||

| 3 1/2 - 16 16-UN | 3.5 | 16 | 0.0625 | 3.4594 | 0.0338 | 0.0156 | 3.4431 | 0.33° | 3.4256 | 0.0203 | 16-UN | 292 | ||

| 3 5/8 - 16 16-UN | 3.625 | 16 | 0.0625 | 3.5844 | 0.0338 | 0.0156 | 3.5681 | 0.32° | 3.5506 | 0.0203 | 16-UN | 297 | ||

| 3 3/4 - 16 16-UN | 3.75 | 16 | 0.0625 | 3.7094 | 0.0338 | 0.0156 | 3.6931 | 0.31° | 3.6756 | 0.0203 | 16-UN | 303 | ||

| 3 7/8 - 16 16-UN | 3.875 | 16 | 0.0625 | 3.8344 | 0.0338 | 0.0156 | 3.8181 | 0.3° | 3.8006 | 0.0203 | 16-UN | 308 | ||

| 4 - 16 16-UN | 4 | 16 | 0.0625 | 3.9594 | 0.0338 | 0.0156 | 3.9431 | 0.29° | 3.9256 | 0.0203 | 16-UN | 314 | ||

| 4 1/8 - 16 16-UN | 4.125 | 16 | 0.0625 | 4.0844 | 0.0338 | 0.0156 | 4.0681 | 0.28° | 4.0506 | 0.0203 | 16-UN | 319 | ||

| 4 1/4 - 16 16-UN | 4.25 | 16 | 0.0625 | 4.2094 | 0.0338 | 0.0156 | 4.1931 | 0.27° | 4.1756 | 0.0203 | 16-UN | 324 | ||

| 4 3/8 - 16 16-UN | 4.375 | 16 | 0.0625 | 4.3344 | 0.0338 | 0.0156 | 4.3181 | 0.26° | 4.3006 | 0.0203 | 16-UN | 329 | ||

| 4 1/2 - 16 16-UN | 4.5 | 16 | 0.0625 | 4.4594 | 0.0338 | 0.0156 | 4.4431 | 0.26° | 4.4256 | 0.0203 | 16-UN | 334 | ||

| 4 5/8 - 16 16-UN | 4.625 | 16 | 0.0625 | 4.5844 | 0.0338 | 0.0156 | 4.5681 | 0.25° | 4.5506 | 0.0203 | 16-UN | 339 | ||

| 4 3/4 - 16 16-UN | 4.75 | 16 | 0.0625 | 4.7094 | 0.0338 | 0.0156 | 4.6931 | 0.24° | 4.6756 | 0.0203 | 16-UN | 345 | ||

| 4 7/8 - 16 16-UN | 4.875 | 16 | 0.0625 | 4.8344 | 0.0338 | 0.0156 | 4.8181 | 0.24° | 4.8006 | 0.0203 | 16-UN | 350 | ||

| 5 - 16 16-UN | 5 | 16 | 0.0625 | 4.9594 | 0.0338 | 0.0156 | 4.9431 | 0.23° | 4.9256 | 0.0203 | 16-UN | 355 | ||

| 5 1/8 - 16 16-UN | 5.125 | 16 | 0.0625 | 5.0844 | 0.0338 | 0.0156 | 5.0681 | 0.22° | 5.0506 | 0.0203 | 16-UN | 360 | ||

| 5 1/4 - 16 16-UN | 5.25 | 16 | 0.0625 | 5.2094 | 0.0338 | 0.0156 | 5.1931 | 0.22° | 5.1756 | 0.0203 | 16-UN | 365 | ||

| 5 3/8 - 16 16-UN | 5.375 | 16 | 0.0625 | 5.3344 | 0.0338 | 0.0156 | 5.3181 | 0.21° | 5.3006 | 0.0203 | 16-UN | 370 | ||

| 5 1/2 - 16 16-UN | 5.5 | 16 | 0.0625 | 5.4594 | 0.0338 | 0.0156 | 5.4431 | 0.21° | 5.4256 | 0.0203 | 16-UN | 375 | ||

| 5 5/8 - 16 16-UN | 5.625 | 16 | 0.0625 | 5.5844 | 0.0338 | 0.0156 | 5.5681 | 0.2° | 5.5506 | 0.0203 | 16-UN | 380 | ||

| 5 3/4 - 16 16-UN | 5.75 | 16 | 0.0625 | 5.7094 | 0.0338 | 0.0156 | 5.6931 | 0.2° | 5.6756 | 0.0203 | 16-UN | 385 | ||

| 5 7/8 - 16 16-UN | 5.875 | 16 | 0.0625 | 5.8344 | 0.0338 | 0.0156 | 5.8181 | 0.2° | 5.8006 | 0.0203 | 16-UN | 390 | ||

| 6 - 16 16-UN | 6 | 16 | 0.0625 | 5.9594 | 0.0338 | 0.0156 | 5.9431 | 0.19° | 5.9256 | 0.0203 | 16-UN | 395 | ||

| 1/4 - 20 20-UN | 0.25 | 20 | 0.0500 | 0.2175 | 0.0271 | 0.0125 | 0.2045 | 4.18° | 0.1905 | 0.0162 | 20-UN | 29 | ||

| 5/16 - 20 20-UN | 0.312 | 20 | 0.0500 | 0.2795 | 0.0271 | 0.0125 | 0.2665 | 3.26° | 0.2525 | 0.0162 | 20-UN | 35 | ||

| 3/8 - 20 20-UN | 0.375 | 20 | 0.0500 | 0.3425 | 0.0271 | 0.0125 | 0.3295 | 2.66° | 0.3155 | 0.0162 | 20-UN | 42 | ||

| 7/16 - 20 20-UN | 0.437 | 20 | 0.0500 | 0.4045 | 0.0271 | 0.0125 | 0.3915 | 2.25° | 0.3775 | 0.0162 | 20-UN | 49 | ||

| 1/2 - 20 20-UN | 0.5 | 20 | 0.0500 | 0.4675 | 0.0271 | 0.0125 | 0.4545 | 1.95° | 0.4405 | 0.0162 | 20-UN | 56 | ||

| 9/16 - 20 20-UN | 0.562 | 20 | 0.0500 | 0.5295 | 0.0271 | 0.0125 | 0.5165 | 1.72° | 0.5025 | 0.0162 | 20-UN | 64 | ||

| 5/8 - 20 20-UN | 0.625 | 20 | 0.0500 | 0.5925 | 0.0271 | 0.0125 | 0.5795 | 1.54° | 0.5655 | 0.0162 | 20-UN | 72 | ||

| 11/16 - 20 20-UN | 0.687 | 20 | 0.0500 | 0.6545 | 0.0271 | 0.0125 | 0.6415 | 1.39° | 0.6275 | 0.0162 | 20-UN | 78 | ||

| 3/4 - 20 20-UN | 0.75 | 20 | 0.0500 | 0.7175 | 0.0271 | 0.0125 | 0.7045 | 1.27° | 0.6905 | 0.0162 | 20-UN | 86 | ||

| 13/16 - 20 20-UN | 0.812 | 20 | 0.0500 | 0.7795 | 0.0271 | 0.0125 | 0.7665 | 1.17° | 0.7525 | 0.0162 | 20-UN | 92 | ||

| 7/8 - 20 20-UN | 0.875 | 20 | 0.0500 | 0.8425 | 0.0271 | 0.0125 | 0.8295 | 1.08° | 0.8155 | 0.0162 | 20-UN | 100 | ||

| 15/16 - 20 20-UN | 0.937 | 20 | 0.0500 | 0.9045 | 0.0271 | 0.0125 | 0.8915 | 1.01° | 0.8775 | 0.0162 | 20-UN | 106 | ||

| 1 - 20 20-UN | 1 | 20 | 0.0500 | 0.9675 | 0.0271 | 0.0125 | 0.9545 | 0.94° | 0.9405 | 0.0162 | 20-UN | 115 | ||

| 1 1/16 - 20 20-UN | 1.062 | 20 | 0.0500 | 1.0295 | 0.0271 | 0.0125 | 1.0165 | 0.89° | 1.0025 | 0.0162 | 20-UN | 122 | ||

| 1 1/8 - 20 20-UN | 1.125 | 20 | 0.0500 | 1.0925 | 0.0271 | 0.0125 | 1.0795 | 0.83° | 1.0655 | 0.0162 | 20-UN | 130 | ||

| 1 3/16 - 20 20-UN | 1.187 | 20 | 0.0500 | 1.1545 | 0.0271 | 0.0125 | 1.1415 | 0.79° | 1.1275 | 0.0162 | 20-UN | 136 | ||

| 1 1/4 - 20 20-UN | 1.25 | 20 | 0.0500 | 1.2175 | 0.0271 | 0.0125 | 1.2045 | 0.75° | 1.1905 | 0.0162 | 20-UN | 144 | ||

| 1 5/16 - 20 20-UN | 1.312 | 20 | 0.0500 | 1.2795 | 0.0271 | 0.0125 | 1.2665 | 0.71° | 1.2525 | 0.0162 | 20-UN | 150 | ||

| 1 3/8 - 20 20-UN | 1.375 | 20 | 0.0500 | 1.3425 | 0.0271 | 0.0125 | 1.3295 | 0.68° | 1.3155 | 0.0162 | 20-UN | 159 | ||

| 1 7/16 - 20 20-UN | 1.437 | 20 | 0.0500 | 1.4045 | 0.0271 | 0.0125 | 1.3915 | 0.65° | 1.3775 | 0.0162 | 20-UN | 166 | ||

| 1 1/2 - 20 20-UN | 1.5 | 20 | 0.0500 | 1.4675 | 0.0271 | 0.0125 | 1.4545 | 0.62° | 1.4405 | 0.0162 | 20-UN | 175 | ||

| 1 9/16 - 20 20-UN | 1.562 | 20 | 0.0500 | 1.5295 | 0.0271 | 0.0125 | 1.5165 | 0.6° | 1.5025 | 0.0162 | 20-UN | 182 | ||

| 1 5/8 - 20 20-UN | 1.625 | 20 | 0.0500 | 1.5925 | 0.0271 | 0.0125 | 1.5795 | 0.57° | 1.5655 | 0.0162 | 20-UN | 188 | ||

| 1 11/16 - 20 20-UN | 1.687 | 20 | 0.0500 | 1.6545 | 0.0271 | 0.0125 | 1.6415 | 0.55° | 1.6275 | 0.0162 | 20-UN | 194 | ||

| 1 3/4 - 20 20-UN | 1.75 | 20 | 0.0500 | 1.7175 | 0.0271 | 0.0125 | 1.7045 | 0.53° | 1.6905 | 0.0162 | 20-UN | 200 | ||

| 1 13/16 - 20 20-UN | 1.812 | 20 | 0.0500 | 1.7795 | 0.0271 | 0.0125 | 1.7665 | 0.51° | 1.7525 | 0.0162 | 20-UN | 205 | ||

| 1 7/8 - 20 20-UN | 1.875 | 20 | 0.0500 | 1.8425 | 0.0271 | 0.0125 | 1.8295 | 0.49° | 1.8155 | 0.0162 | 20-UN | 210 | ||

| 1 15/16 - 20 20-UN | 1.937 | 20 | 0.0500 | 1.9045 | 0.0271 | 0.0125 | 1.8915 | 0.48° | 1.8775 | 0.0162 | 20-UN | 215 | ||

| 2 - 20 20-UN | 2 | 20 | 0.0500 | 1.9675 | 0.0271 | 0.0125 | 1.9545 | 0.46° | 1.9405 | 0.0162 | 20-UN | 221 | ||

| 2 1/8 - 20 20-UN | 2.125 | 20 | 0.0500 | 2.0925 | 0.0271 | 0.0125 | 2.0795 | 0.44° | 2.0655 | 0.0162 | 20-UN | 226 | ||

| 2 1/4 - 20 20-UN | 2.25 | 20 | 0.0500 | 2.2175 | 0.0271 | 0.0125 | 2.2045 | 0.41° | 2.1905 | 0.0162 | 20-UN | 232 | ||

| 2 3/8 - 20 20-UN | 2.375 | 20 | 0.0500 | 2.3425 | 0.0271 | 0.0125 | 2.3295 | 0.39° | 2.3155 | 0.0162 | 20-UN | 237 | ||

| 2 1/2 - 20 20-UN | 2.5 | 20 | 0.0500 | 2.4675 | 0.0271 | 0.0125 | 2.4545 | 0.37° | 2.4405 | 0.0162 | 20-UN | 244 | ||

| 2 5/8 - 20 20-UN | 2.625 | 20 | 0.0500 | 2.5925 | 0.0271 | 0.0125 | 2.5795 | 0.35° | 2.5655 | 0.0162 | 20-UN | 250 | ||

| 2 3/4 - 20 20-UN | 2.75 | 20 | 0.0500 | 2.7175 | 0.0271 | 0.0125 | 2.7045 | 0.34° | 2.6905 | 0.0162 | 20-UN | 257 | ||

| 2 7/8 - 20 20-UN | 2.875 | 20 | 0.0500 | 2.8425 | 0.0271 | 0.0125 | 2.8295 | 0.32° | 2.8155 | 0.0162 | 20-UN | 263 | ||

| 3 - 20 20-UN | 3 | 20 | 0.0500 | 2.9675 | 0.0271 | 0.0125 | 2.9545 | 0.31° | 2.9405 | 0.0162 | 20-UN | 270 | ||

| 4 5/8 - 20-UN | 4.625 | 20 | 0.0500 | 4.5925 | 0.0271 | 0.0125 | 4.5795 | 0.2° | 4.5655 | 0.0162 | 20-UN | 340 | ||

| #12 - 28 28-UN | 0.216 | 28 | 0.0357 | 0.1928 | 0.0193 | 0.0089 | 0.1835 | 3.37° | 0.1735 | 0.0116 | 28-UN | 24 | ||

| 1/4 - 28 28-UN | 0.25 | 28 | 0.0357 | 0.2268 | 0.0193 | 0.0089 | 0.2175 | 2.87° | 0.2075 | 0.0116 | 28-UN | 30 | ||

| 5/16 - 28 28-UN | 0.312 | 28 | 0.0357 | 0.2888 | 0.0193 | 0.0089 | 0.2795 | 2.25° | 0.2695 | 0.0116 | 28-UN | 36 | ||

| 3/8 - 28 28-UN | 0.375 | 28 | 0.0357 | 0.3518 | 0.0193 | 0.0089 | 0.3425 | 1.85° | 0.3325 | 0.0116 | 28-UN | 43 | ||

| 7/16 - 28 28-UN | 0.437 | 28 | 0.0357 | 0.4138 | 0.0193 | 0.0089 | 0.4045 | 1.57° | 0.3945 | 0.0116 | 28-UN | 50 | ||

| 1/2 - 28 28-UN | 0.5 | 28 | 0.0357 | 0.4768 | 0.0193 | 0.0089 | 0.4675 | 1.37° | 0.4575 | 0.0116 | 28-UN | 57 | ||

| 9/16 - 28 28-UN | 0.562 | 28 | 0.0357 | 0.5388 | 0.0193 | 0.0089 | 0.5295 | 1.21° | 0.5195 | 0.0116 | 28-UN | 65 | ||

| 5/8 - 28 28-UN | 0.625 | 28 | 0.0357 | 0.6018 | 0.0193 | 0.0089 | 0.5925 | 1.08° | 0.5825 | 0.0116 | 28-UN | 73 | ||

| 11/16 - 28 28-UN | 0.687 | 28 | 0.0357 | 0.6638 | 0.0193 | 0.0089 | 0.6545 | 0.98° | 0.6445 | 0.0116 | 28-UN | 79 | ||

| 3/4 - 28 28-UN | 0.75 | 28 | 0.0357 | 0.7268 | 0.0193 | 0.0089 | 0.7175 | 0.9° | 0.7075 | 0.0116 | 28-UN | 87 | ||

| 13/16 - 28 28-UN | 0.812 | 28 | 0.0357 | 0.7888 | 0.0193 | 0.0089 | 0.7795 | 0.83° | 0.7695 | 0.0116 | 28-UN | 93 | ||

| 7/8 - 28 28-UN | 0.875 | 28 | 0.0357 | 0.8518 | 0.0193 | 0.0089 | 0.8425 | 0.76° | 0.8325 | 0.0116 | 28-UN | 101 | ||

| 15/16 - 28 28-UN | 0.937 | 28 | 0.0357 | 0.9138 | 0.0193 | 0.0089 | 0.9045 | 0.71° | 0.8945 | 0.0116 | 28-UN | 107 | ||

| 1 - 28 28-UN | 1 | 28 | 0.0357 | 0.9768 | 0.0193 | 0.0089 | 0.9675 | 0.67° | 0.9575 | 0.0116 | 28-UN | 116 | ||

| 1 1/16 - 28 28-UN | 1.062 | 28 | 0.0357 | 1.0388 | 0.0193 | 0.0089 | 1.0295 | 0.63° | 1.0195 | 0.0116 | 28-UN | 123 | ||

| 1 1/8 - 28 28-UN | 1.125 | 28 | 0.0357 | 1.1018 | 0.0193 | 0.0089 | 1.0925 | 0.59° | 1.0825 | 0.0116 | 28-UN | 131 | ||

| 1 3/16 - 28 28-UN | 1.187 | 28 | 0.0357 | 1.1638 | 0.0193 | 0.0089 | 1.1545 | 0.56° | 1.1445 | 0.0116 | 28-UN | 137 | ||

| 1 1/4 - 28 28-UN | 1.25 | 28 | 0.0357 | 1.2268 | 0.0193 | 0.0089 | 1.2175 | 0.53° | 1.2075 | 0.0116 | 28-UN | 145 | ||

| 1 5/16 - 28 28-UN | 1.312 | 28 | 0.0357 | 1.2888 | 0.0193 | 0.0089 | 1.2795 | 0.51° | 1.2695 | 0.0116 | 28-UN | 151 | ||

| 1 3/8 - 28 28-UN | 1.375 | 28 | 0.0357 | 1.3518 | 0.0193 | 0.0089 | 1.3425 | 0.48° | 1.3325 | 0.0116 | 28-UN | 160 | ||

| 1 7/16 - 28 28-UN | 1.437 | 28 | 0.0357 | 1.4138 | 0.0193 | 0.0089 | 1.4045 | 0.46° | 1.3945 | 0.0116 | 28-UN | 167 | ||

| 1 1/2 - 28 28-UN | 1.5 | 28 | 0.0357 | 1.4768 | 0.0193 | 0.0089 | 1.4675 | 0.44° | 1.4575 | 0.0116 | 28-UN | 176 | ||

| #6 - 32 32-UN | 0.138 | 32 | 0.0313 | 0.1177 | 0.0169 | 0.0078 | 0.1096 | 4.83° | 0.1008 | 0.0101 | 32-UN | 14 | ||

| #8 - 32 32-UN | 0.164 | 32 | 0.0313 | 0.1437 | 0.0169 | 0.0078 | 0.1356 | 3.96° | 0.1268 | 0.0101 | 32-UN | 17 | ||

| #10 - 32 32-UN | 0.19 | 32 | 0.0313 | 0.1697 | 0.0169 | 0.0078 | 0.1616 | 3.35° | 0.1528 | 0.0101 | 32-UN | 20 | ||

| #12 - 32 32-UN | 0.216 | 32 | 0.0313 | 0.1957 | 0.0169 | 0.0078 | 0.1876 | 2.91° | 0.1788 | 0.0101 | 32-UN | 25 | ||

| 1/4 - 32 32-UN | 0.25 | 32 | 0.0313 | 0.2297 | 0.0169 | 0.0078 | 0.2216 | 2.48° | 0.2128 | 0.0101 | 32-UN | 31 | ||

| 5/16 - 32 32-UN | 0.312 | 32 | 0.0313 | 0.2917 | 0.0169 | 0.0078 | 0.2836 | 1.95° | 0.2748 | 0.0101 | 32-UN | 37 | ||

| 3/8 - 32 32-UN | 0.375 | 32 | 0.0313 | 0.3547 | 0.0169 | 0.0078 | 0.3466 | 1.61° | 0.3378 | 0.0101 | 32-UN | 44 | ||

| 7/16 - 32 32-UN | 0.437 | 32 | 0.0313 | 0.4167 | 0.0169 | 0.0078 | 0.4086 | 1.37° | 0.3998 | 0.0101 | 32-UN | 51 | ||

| 1/2 - 32 32-UN | 0.5 | 32 | 0.0313 | 0.4797 | 0.0169 | 0.0078 | 0.4716 | 1.19° | 0.4628 | 0.0101 | 32-UN | 58 | ||

| 9/16 - 32 32-UN | 0.562 | 32 | 0.0313 | 0.5417 | 0.0169 | 0.0078 | 0.5336 | 1.05° | 0.5248 | 0.0101 | 32-UN | 66 | ||

| 5/8 - 32 32-UN | 0.625 | 32 | 0.0313 | 0.6047 | 0.0169 | 0.0078 | 0.5966 | 0.94° | 0.5878 | 0.0101 | 32-UN | 74 | ||

| 11/16 - 32 32-UN | 0.687 | 32 | 0.0313 | 0.6667 | 0.0169 | 0.0078 | 0.6586 | 0.85° | 0.6498 | 0.0101 | 32-UN | 80 | ||

| 3/4 - 32 32-UN | 0.75 | 32 | 0.0313 | 0.7297 | 0.0169 | 0.0078 | 0.7216 | 0.78° | 0.7128 | 0.0101 | 32-UN | 88 | ||

| 13/16 - 32 32-UN | 0.812 | 32 | 0.0313 | 0.7917 | 0.0169 | 0.0078 | 0.7836 | 0.72° | 0.7748 | 0.0101 | 32-UN | 94 | ||

| 7/8 - 32 32-UN | 0.875 | 32 | 0.0313 | 0.8547 | 0.0169 | 0.0078 | 0.8466 | 0.67° | 0.8378 | 0.0101 | 32-UN | 102 | ||

| 15/16 - 32 32-UN | 0.937 | 32 | 0.0313 | 0.9167 | 0.0169 | 0.0078 | 0.9086 | 0.62° | 0.8998 | 0.0101 | 32-UN | 108 | ||

| 1 - 32 32-UN | 1 | 32 | 0.0313 | 0.9797 | 0.0169 | 0.0078 | 0.9716 | 0.58° | 0.9628 | 0.0101 | 32-UN | 117 | ||

| 2 1/2 - 4 4-UN | 2.5 | 4 | 0.2500 | 2.3376 | 0.1353 | 0.0625 | 2.2725 | 1.95° | 2.2023 | 0.0812 | 4-UN | 239 | ||

| 2 5/8 - 4 4-UN | 2.625 | 4 | 0.2500 | 2.4626 | 0.1353 | 0.0625 | 2.3975 | 1.85° | 2.3273 | 0.0812 | 4-UN | 245 | ||

| 2 3/4 - 4 4-UN | 2.75 | 4 | 0.2500 | 2.5876 | 0.1353 | 0.0625 | 2.5225 | 1.76° | 2.4523 | 0.0812 | 4-UN | 252 | ||

| 2 7/8 - 4 4-UN | 2.875 | 4 | 0.2500 | 2.7126 | 0.1353 | 0.0625 | 2.6475 | 1.68° | 2.5773 | 0.0812 | 4-UN | 258 | ||

| 3 - 4 4-UN | 3 | 4 | 0.2500 | 2.8376 | 0.1353 | 0.0625 | 2.7725 | 1.61° | 2.7023 | 0.0812 | 4-UN | 265 | ||

| 3 1/8 - 4 4-UN | 3.125 | 4 | 0.2500 | 2.9626 | 0.1353 | 0.0625 | 2.8975 | 1.54° | 2.8273 | 0.0812 | 4-UN | 271 | ||

| 3 1/4 - 4 4-UN | 3.25 | 4 | 0.2500 | 3.0876 | 0.1353 | 0.0625 | 3.0225 | 1.48° | 2.9523 | 0.0812 | 4-UN | 277 | ||

| 3 3/8 - 4 4-UN | 3.375 | 4 | 0.2500 | 3.2126 | 0.1353 | 0.0625 | 3.1475 | 1.42° | 3.0773 | 0.0812 | 4-UN | 282 | ||

| 3 1/2 - 4 4-UN | 3.5 | 4 | 0.2500 | 3.3376 | 0.1353 | 0.0625 | 3.2725 | 1.37° | 3.2023 | 0.0812 | 4-UN | 288 | ||

| 3 5/8 - 4 4-UN | 3.625 | 4 | 0.2500 | 3.4626 | 0.1353 | 0.0625 | 3.3975 | 1.32° | 3.3273 | 0.0812 | 4-UN | 293 | ||

| 3 3/4 - 4 4-UN | 3.75 | 4 | 0.2500 | 3.5876 | 0.1353 | 0.0625 | 3.5225 | 1.27° | 3.4523 | 0.0812 | 4-UN | 299 | ||

| 3 7/8 - 4 4-UN | 3.875 | 4 | 0.2500 | 3.7126 | 0.1353 | 0.0625 | 3.6475 | 1.23° | 3.5773 | 0.0812 | 4-UN | 304 | ||

| 4 - 4 4-UN | 4 | 4 | 0.2500 | 3.8376 | 0.1353 | 0.0625 | 3.7725 | 1.19° | 3.7023 | 0.0812 | 4-UN | 310 | ||

| 4 1/8 - 4 4-UN | 4.125 | 4 | 0.2500 | 3.9626 | 0.1353 | 0.0625 | 3.8975 | 1.15° | 3.8273 | 0.0812 | 4-UN | 315 | ||

| 4 1/4 - 4 4-UN | 4.25 | 4 | 0.2500 | 4.0876 | 0.1353 | 0.0625 | 4.0225 | 1.12° | 3.9523 | 0.0812 | 4-UN | 320 | ||

| 4 3/8 - 4 4-UN | 4.375 | 4 | 0.2500 | 4.2126 | 0.1353 | 0.0625 | 4.1475 | 1.08° | 4.0773 | 0.0812 | 4-UN | 325 | ||

| 4 1/2 - 4 4-UN | 4.5 | 4 | 0.2500 | 4.3376 | 0.1353 | 0.0625 | 4.2725 | 1.05° | 4.2023 | 0.0812 | 4-UN | 330 | ||

| 4 5/8 - 4 4-UN | 4.625 | 4 | 0.2500 | 4.4626 | 0.1353 | 0.0625 | 4.3975 | 1.02° | 4.3273 | 0.0812 | 4-UN | 335 | ||

| 4 3/4 - 4 4-UN | 4.75 | 4 | 0.2500 | 4.5876 | 0.1353 | 0.0625 | 4.5225 | 0.99° | 4.4523 | 0.0812 | 4-UN | 341 | ||

| 4 7/8 - 4 4-UN | 4.875 | 4 | 0.2500 | 4.7126 | 0.1353 | 0.0625 | 4.6475 | 0.97° | 4.5773 | 0.0812 | 4-UN | 346 | ||

| 5 - 4 4-UN | 5 | 4 | 0.2500 | 4.8376 | 0.1353 | 0.0625 | 4.7725 | 0.94° | 4.7023 | 0.0812 | 4-UN | 351 | ||

| 5 1/8 - 4 4-UN | 5.125 | 4 | 0.2500 | 4.9626 | 0.1353 | 0.0625 | 4.8975 | 0.92° | 4.8273 | 0.0812 | 4-UN | 356 | ||

| 5 1/4 - 4 4-UN | 5.25 | 4 | 0.2500 | 5.0876 | 0.1353 | 0.0625 | 5.0225 | 0.9° | 4.9523 | 0.0812 | 4-UN | 361 | ||

| 5 3/8 - 4 4-UN | 5.375 | 4 | 0.2500 | 5.2126 | 0.1353 | 0.0625 | 5.1475 | 0.87° | 5.0773 | 0.0812 | 4-UN | 366 | ||

| 5 1/2 - 4 4-UN | 5.5 | 4 | 0.2500 | 5.3376 | 0.1353 | 0.0625 | 5.2725 | 0.85° | 5.2023 | 0.0812 | 4-UN | 371 | ||

| 5 5/8 - 4 4-UN | 5.625 | 4 | 0.2500 | 5.4626 | 0.1353 | 0.0625 | 5.3975 | 0.83° | 5.3273 | 0.0812 | 4-UN | 376 | ||

| 5 3/4 - 4 4-UN | 5.75 | 4 | 0.2500 | 5.5876 | 0.1353 | 0.0625 | 5.5225 | 0.82° | 5.4523 | 0.0812 | 4-UN | 381 | ||

| 5 7/8 - 4 4-UN | 5.875 | 4 | 0.2500 | 5.7126 | 0.1353 | 0.0625 | 5.6475 | 0.8° | 5.5773 | 0.0812 | 4-UN | 386 | ||

| 6 - 4 4-UN | 6 | 4 | 0.2500 | 5.8376 | 0.1353 | 0.0625 | 5.7725 | 0.78° | 5.7023 | 0.0812 | 4-UN | 391 | ||

| 1 3/8 - 6 6-UN | 1.375 | 6 | 0.1667 | 1.2667 | 0.0902 | 0.0417 | 1.2233 | 2.4° | 1.1765 | 0.0541 | 6-UN | 155 | ||

| 1 7/16 - 6 6-UN | 1.437 | 6 | 0.1667 | 1.3287 | 0.0902 | 0.0417 | 1.2853 | 2.29° | 1.2385 | 0.0541 | 6-UN | 162 | ||

| 1 1/2 - 6 6-UN | 1.5 | 6 | 0.1667 | 1.3917 | 0.0902 | 0.0417 | 1.3483 | 2.18° | 1.3015 | 0.0541 | 6-UN | 171 | ||

| 1 9/16 - 6 6-UN | 1.562 | 6 | 0.1667 | 1.4537 | 0.0902 | 0.0417 | 1.4103 | 2.09° | 1.3635 | 0.0541 | 6-UN | 178 | ||

| 1 5/8 - 6 6-UN | 1.625 | 6 | 0.1667 | 1.5167 | 0.0902 | 0.0417 | 1.4733 | 2° | 1.4265 | 0.0541 | 6-UN | 184 | ||

| 1 11/16 - 6 6-UN | 1.687 | 6 | 0.1667 | 1.5787 | 0.0902 | 0.0417 | 1.5353 | 1.92° | 1.4885 | 0.0541 | 6-UN | 190 | ||

| 1 3/4 - 6 6-UN | 1.75 | 6 | 0.1667 | 1.6417 | 0.0902 | 0.0417 | 1.5983 | 1.85° | 1.5515 | 0.0541 | 6-UN | 196 | ||

| 1 13/16 - 6 6-UN | 1.812 | 6 | 0.1667 | 1.7037 | 0.0902 | 0.0417 | 1.6603 | 1.78° | 1.6135 | 0.0541 | 6-UN | 201 | ||

| 1 7/8 - 6 6-UN | 1.875 | 6 | 0.1667 | 1.7667 | 0.0902 | 0.0417 | 1.7233 | 1.72° | 1.6765 | 0.0541 | 6-UN | 206 | ||

| 1 15/16 - 6 6-UN | 1.937 | 6 | 0.1667 | 1.8287 | 0.0902 | 0.0417 | 1.7853 | 1.66° | 1.7385 | 0.0541 | 6-UN | 211 | ||

| 2 - 6 6-UN | 2 | 6 | 0.1667 | 1.8917 | 0.0902 | 0.0417 | 1.8483 | 1.61° | 1.8015 | 0.0541 | 6-UN | 217 | ||

| 2 1/8 - 6 6-UN | 2.125 | 6 | 0.1667 | 2.0167 | 0.0902 | 0.0417 | 1.9733 | 1.51° | 1.9265 | 0.0541 | 6-UN | 222 | ||

| 2 1/4 - 6 6-UN | 2.25 | 6 | 0.1667 | 2.1417 | 0.0902 | 0.0417 | 2.0983 | 1.42° | 2.0515 | 0.0541 | 6-UN | 228 | ||

| 2 3/8 - 6 6-UN | 2.375 | 6 | 0.1667 | 2.2667 | 0.0902 | 0.0417 | 2.2233 | 1.34° | 2.1765 | 0.0541 | 6-UN | 233 | ||

| 2 1/2 - 6 6-UN | 2.5 | 6 | 0.1667 | 2.3917 | 0.0902 | 0.0417 | 2.3483 | 1.27° | 2.3015 | 0.0541 | 6-UN | 240 | ||

| 2 5/8 - 6 6-UN | 2.625 | 6 | 0.1667 | 2.5167 | 0.0902 | 0.0417 | 2.4733 | 1.21° | 2.4265 | 0.0541 | 6-UN | 246 | ||

| 2 3/4 - 6 6-UN | 2.75 | 6 | 0.1667 | 2.6417 | 0.0902 | 0.0417 | 2.5983 | 1.15° | 2.5515 | 0.0541 | 6-UN | 253 | ||

| 2 7/8 - 6 6-UN | 2.875 | 6 | 0.1667 | 2.7667 | 0.0902 | 0.0417 | 2.7233 | 1.1° | 2.6765 | 0.0541 | 6-UN | 259 | ||

| 3 - 6 6-UN | 3 | 6 | 0.1667 | 2.8917 | 0.0902 | 0.0417 | 2.8483 | 1.05° | 2.8015 | 0.0541 | 6-UN | 266 | ||

| 3 1/8 - 6 6-UN | 3.125 | 6 | 0.1667 | 3.0167 | 0.0902 | 0.0417 | 2.9733 | 1.01° | 2.9265 | 0.0541 | 6-UN | 272 | ||

| 3 1/4 - 6 6-UN | 3.25 | 6 | 0.1667 | 3.1417 | 0.0902 | 0.0417 | 3.0983 | 0.97° | 3.0515 | 0.0541 | 6-UN | 278 | ||

| 3 3/8 - 6 6-UN | 3.375 | 6 | 0.1667 | 3.2667 | 0.0902 | 0.0417 | 3.2233 | 0.93° | 3.1765 | 0.0541 | 6-UN | 283 | ||

| 3 1/2 - 6 6-UN | 3.5 | 6 | 0.1667 | 3.3917 | 0.0902 | 0.0417 | 3.3483 | 0.9° | 3.3015 | 0.0541 | 6-UN | 289 | ||

| 3 5/8 - 6 6-UN | 3.625 | 6 | 0.1667 | 3.5167 | 0.0902 | 0.0417 | 3.4733 | 0.86° | 3.4265 | 0.0541 | 6-UN | 294 | ||

| 3 3/4 - 6 6-UN | 3.75 | 6 | 0.1667 | 3.6417 | 0.0902 | 0.0417 | 3.5983 | 0.83° | 3.5515 | 0.0541 | 6-UN | 300 | ||

| 3 7/8 - 6 6-UN | 3.875 | 6 | 0.1667 | 3.7667 | 0.0902 | 0.0417 | 3.7233 | 0.81° | 3.6765 | 0.0541 | 6-UN | 305 | ||

| 4 - 6 6-UN | 4 | 6 | 0.1667 | 3.8917 | 0.0902 | 0.0417 | 3.8483 | 0.78° | 3.8015 | 0.0541 | 6-UN | 311 | ||

| 4 1/8 - 6 6-UN | 4.125 | 6 | 0.1667 | 4.0167 | 0.0902 | 0.0417 | 3.9733 | 0.76° | 3.9265 | 0.0541 | 6-UN | 316 | ||

| 4 1/4 - 6 6-UN | 4.25 | 6 | 0.1667 | 4.1417 | 0.0902 | 0.0417 | 4.0983 | 0.73° | 4.0515 | 0.0541 | 6-UN | 321 | ||

| 4 3/8 - 6 6-UN | 4.375 | 6 | 0.1667 | 4.2667 | 0.0902 | 0.0417 | 4.2233 | 0.71° | 4.1765 | 0.0541 | 6-UN | 326 | ||

| 4 1/2 - 6 6-UN | 4.5 | 6 | 0.1667 | 4.3917 | 0.0902 | 0.0417 | 4.3483 | 0.69° | 4.3015 | 0.0541 | 6-UN | 331 | ||

| 4 5/8 - 6 6-UN | 4.625 | 6 | 0.1667 | 4.5167 | 0.0902 | 0.0417 | 4.4733 | 0.67° | 4.4265 | 0.0541 | 6-UN | 336 | ||

| 4 3/4 - 6 6-UN | 4.75 | 6 | 0.1667 | 4.6417 | 0.0902 | 0.0417 | 4.5983 | 0.65° | 4.5515 | 0.0541 | 6-UN | 342 | ||

| 4 7/8 - 6 6-UN | 4.875 | 6 | 0.1667 | 4.7667 | 0.0902 | 0.0417 | 4.7233 | 0.64° | 4.6765 | 0.0541 | 6-UN | 347 | ||

| 5 - 6 6-UN | 5 | 6 | 0.1667 | 4.8917 | 0.0902 | 0.0417 | 4.8483 | 0.62° | 4.8015 | 0.0541 | 6-UN | 352 | ||

| 5 1/8 - 6 6-UN | 5.125 | 6 | 0.1667 | 5.0167 | 0.0902 | 0.0417 | 4.9733 | 0.61° | 4.9265 | 0.0541 | 6-UN | 357 | ||

| 5 1/4 - 6 6-UN | 5.25 | 6 | 0.1667 | 5.1417 | 0.0902 | 0.0417 | 5.0983 | 0.59° | 5.0515 | 0.0541 | 6-UN | 362 | ||

| 5 3/8 - 6 6-UN | 5.375 | 6 | 0.1667 | 5.2667 | 0.0902 | 0.0417 | 5.2233 | 0.58° | 5.1765 | 0.0541 | 6-UN | 367 | ||

| 5 1/2 - 6 6-UN | 5.5 | 6 | 0.1667 | 5.3917 | 0.0902 | 0.0417 | 5.3483 | 0.56° | 5.3015 | 0.0541 | 6-UN | 372 | ||

| 5 5/8 - 6 6-UN | 5.625 | 6 | 0.1667 | 5.5167 | 0.0902 | 0.0417 | 5.4733 | 0.55° | 5.4265 | 0.0541 | 6-UN | 377 | ||

| 5 3/4 - 6 6-UN | 5.75 | 6 | 0.1667 | 5.6417 | 0.0902 | 0.0417 | 5.5983 | 0.54° | 5.5515 | 0.0541 | 6-UN | 382 | ||

| 5 7/8 - 6 6-UN | 5.875 | 6 | 0.1667 | 5.7667 | 0.0902 | 0.0417 | 5.7233 | 0.53° | 5.6765 | 0.0541 | 6-UN | 387 | ||

| 6 - 6 6-UN | 6 | 6 | 0.1667 | 5.8917 | 0.0902 | 0.0417 | 5.8483 | 0.52° | 5.8015 | 0.0541 | 6-UN | 392 | ||

| 1 - 8 8-UN | 1 | 8 | 0.1250 | 0.9188 | 0.0677 | 0.0313 | 0.8863 | 2.48° | 0.8512 | 0.0406 | 8-UN | 112 | ||

| 1 1/16 - 8 8-UN | 1.062 | 8 | 0.1250 | 0.9808 | 0.0677 | 0.0313 | 0.9483 | 2.32° | 0.9132 | 0.0406 | 8-UN | 119 | ||

| 1 1/8 - 8 8-UN | 1.125 | 8 | 0.1250 | 1.0438 | 0.0677 | 0.0313 | 1.0113 | 2.18° | 0.9762 | 0.0406 | 8-UN | 127 | ||

| 1 3/16 - 8 8-UN | 1.187 | 8 | 0.1250 | 1.1058 | 0.0677 | 0.0313 | 1.0733 | 2.06° | 1.0382 | 0.0406 | 8-UN | 133 | ||

| 1 1/4 - 8 8-UN | 1.25 | 8 | 0.1250 | 1.1688 | 0.0677 | 0.0313 | 1.1363 | 1.95° | 1.1012 | 0.0406 | 8-UN | 141 | ||

| 1 5/16 - 8 8-UN | 1.312 | 8 | 0.1250 | 1.2308 | 0.0677 | 0.0313 | 1.1983 | 1.85° | 1.1632 | 0.0406 | 8-UN | 147 | ||

| 1 3/8 - 8 8-UN | 1.375 | 8 | 0.1250 | 1.2938 | 0.0677 | 0.0313 | 1.2613 | 1.76° | 1.2262 | 0.0406 | 8-UN | 156 | ||

| 1 7/16 - 8 8-UN | 1.437 | 8 | 0.1250 | 1.3558 | 0.0677 | 0.0313 | 1.3233 | 1.68° | 1.2882 | 0.0406 | 8-UN | 163 | ||

| 1 1/2 - 8 8-UN | 1.5 | 8 | 0.1250 | 1.4188 | 0.0677 | 0.0313 | 1.3863 | 1.61° | 1.3512 | 0.0406 | 8-UN | 172 | ||

| 1 9/16 - 8 8-UN | 1.562 | 8 | 0.1250 | 1.4808 | 0.0677 | 0.0313 | 1.4483 | 1.54° | 1.4132 | 0.0406 | 8-UN | 179 | ||

| 1 5/8 - 8 8-UN | 1.625 | 8 | 0.1250 | 1.5438 | 0.0677 | 0.0313 | 1.5113 | 1.48° | 1.4762 | 0.0406 | 8-UN | 185 | ||

| 1 11/16 - 8 8-UN | 1.687 | 8 | 0.1250 | 1.6058 | 0.0677 | 0.0313 | 1.5733 | 1.42° | 1.5382 | 0.0406 | 8-UN | 191 | ||

| 1 3/4 - 8 8-UN | 1.75 | 8 | 0.1250 | 1.6688 | 0.0677 | 0.0313 | 1.6363 | 1.37° | 1.6012 | 0.0406 | 8-UN | 197 | ||

| 1 13/16 - 8 8-UN | 1.812 | 8 | 0.1250 | 1.7308 | 0.0677 | 0.0313 | 1.6983 | 1.32° | 1.6632 | 0.0406 | 8-UN | 202 | ||

| 1 7/8 - 8 8-UN | 1.875 | 8 | 0.1250 | 1.7938 | 0.0677 | 0.0313 | 1.7613 | 1.27° | 1.7262 | 0.0406 | 8-UN | 207 | ||

| 1 15/16 - 8 8-UN | 1.937 | 8 | 0.1250 | 1.8558 | 0.0677 | 0.0313 | 1.8233 | 1.23° | 1.7882 | 0.0406 | 8-UN | 212 | ||

| 2 - 8 8-UN | 2 | 8 | 0.1250 | 1.9188 | 0.0677 | 0.0313 | 1.8863 | 1.19° | 1.8512 | 0.0406 | 8-UN | 218 | ||

| 2 1/8 - 8 8-UN | 2.125 | 8 | 0.1250 | 2.0438 | 0.0677 | 0.0313 | 2.0113 | 1.12° | 1.9762 | 0.0406 | 8-UN | 223 | ||

| 2 1/4 - 8 8-UN | 2.25 | 8 | 0.1250 | 2.1688 | 0.0677 | 0.0313 | 2.1363 | 1.05° | 2.1012 | 0.0406 | 8-UN | 229 | ||

| 2 3/8 - 8 8-UN | 2.375 | 8 | 0.1250 | 2.2938 | 0.0677 | 0.0313 | 2.2613 | 0.99° | 2.2262 | 0.0406 | 8-UN | 234 | ||

| 2 1/2 - 8 8-UN | 2.5 | 8 | 0.1250 | 2.4188 | 0.0677 | 0.0313 | 2.3863 | 0.94° | 2.3512 | 0.0406 | 8-UN | 241 | ||

| 2 5/8 - 8 8-UN | 2.625 | 8 | 0.1250 | 2.5438 | 0.0677 | 0.0313 | 2.5113 | 0.9° | 2.4762 | 0.0406 | 8-UN | 247 | ||

| 2 3/4 - 8 8-UN | 2.75 | 8 | 0.1250 | 2.6688 | 0.0677 | 0.0313 | 2.6363 | 0.85° | 2.6012 | 0.0406 | 8-UN | 254 | ||

| 2 7/8 - 8 8-UN | 2.875 | 8 | 0.1250 | 2.7938 | 0.0677 | 0.0313 | 2.7613 | 0.82° | 2.7262 | 0.0406 | 8-UN | 260 | ||

| 3 - 8 8-UN | 3 | 8 | 0.1250 | 2.9188 | 0.0677 | 0.0313 | 2.8863 | 0.78° | 2.8512 | 0.0406 | 8-UN | 267 | ||

| 3 1/8 - 8 8-UN | 3.125 | 8 | 0.1250 | 3.0438 | 0.0677 | 0.0313 | 3.0113 | 0.75° | 2.9762 | 0.0406 | 8-UN | 273 | ||

| 3 1/4 - 8 8-UN | 3.25 | 8 | 0.1250 | 3.1688 | 0.0677 | 0.0313 | 3.1363 | 0.72° | 3.1012 | 0.0406 | 8-UN | 279 | ||

| 3 3/8 - 8 8-UN | 3.375 | 8 | 0.1250 | 3.2938 | 0.0677 | 0.0313 | 3.2613 | 0.69° | 3.2262 | 0.0406 | 8-UN | 284 | ||

| 3 1/2 - 8 8-UN | 3.5 | 8 | 0.1250 | 3.4188 | 0.0677 | 0.0313 | 3.3863 | 0.67° | 3.3512 | 0.0406 | 8-UN | 290 | ||

| 3 5/8 - 8 8-UN | 3.625 | 8 | 0.1250 | 3.5438 | 0.0677 | 0.0313 | 3.5113 | 0.64° | 3.4762 | 0.0406 | 8-UN | 295 | ||

| 3 3/4 - 8 8-UN | 3.75 | 8 | 0.1250 | 3.6688 | 0.0677 | 0.0313 | 3.6363 | 0.62° | 3.6012 | 0.0406 | 8-UN | 301 | ||

| 3 7/8 - 8 8-UN | 3.875 | 8 | 0.1250 | 3.7938 | 0.0677 | 0.0313 | 3.7613 | 0.6° | 3.7262 | 0.0406 | 8-UN | 306 | ||

| 4 - 8 8-UN | 4 | 8 | 0.1250 | 3.9188 | 0.0677 | 0.0313 | 3.8863 | 0.58° | 3.8512 | 0.0406 | 8-UN | 312 | ||

| 4 1/8 - 8 8-UN | 4.125 | 8 | 0.1250 | 4.0438 | 0.0677 | 0.0313 | 4.0113 | 0.56° | 3.9762 | 0.0406 | 8-UN | 317 | ||

| 4 1/4 - 8 8-UN | 4.25 | 8 | 0.1250 | 4.1688 | 0.0677 | 0.0313 | 4.1363 | 0.55° | 4.1012 | 0.0406 | 8-UN | 322 | ||

| 4 3/8 - 8 8-UN | 4.375 | 8 | 0.1250 | 4.2938 | 0.0677 | 0.0313 | 4.2613 | 0.53° | 4.2262 | 0.0406 | 8-UN | 327 | ||

| 4 1/2 - 8 8-UN | 4.5 | 8 | 0.1250 | 4.4188 | 0.0677 | 0.0313 | 4.3863 | 0.52° | 4.3512 | 0.0406 | 8-UN | 332 | ||

| 4 5/8 - 8 8-UN | 4.625 | 8 | 0.1250 | 4.5438 | 0.0677 | 0.0313 | 4.5113 | 0.5° | 4.4762 | 0.0406 | 8-UN | 337 | ||

| 4 3/4 - 8 8-UN | 4.75 | 8 | 0.1250 | 4.6688 | 0.0677 | 0.0313 | 4.6363 | 0.49° | 4.6012 | 0.0406 | 8-UN | 343 | ||

| 4 7/8 - 8 8-UN | 4.875 | 8 | 0.1250 | 4.7938 | 0.0677 | 0.0313 | 4.7613 | 0.48° | 4.7262 | 0.0406 | 8-UN | 348 | ||

| 5 - 8 8-UN | 5 | 8 | 0.1250 | 4.9188 | 0.0677 | 0.0313 | 4.8863 | 0.46° | 4.8512 | 0.0406 | 8-UN | 353 | ||

| 5 1/8 - 8 8-UN | 5.125 | 8 | 0.1250 | 5.0438 | 0.0677 | 0.0313 | 5.0113 | 0.45° | 4.9762 | 0.0406 | 8-UN | 358 | ||

| 5 1/4 - 8 8-UN | 5.25 | 8 | 0.1250 | 5.1688 | 0.0677 | 0.0313 | 5.1363 | 0.44° | 5.1012 | 0.0406 | 8-UN | 363 | ||

| 5 3/8 - 8 8-UN | 5.375 | 8 | 0.1250 | 5.2938 | 0.0677 | 0.0313 | 5.2613 | 0.43° | 5.2262 | 0.0406 | 8-UN | 368 | ||

| 5 1/2 - 8 8-UN | 5.5 | 8 | 0.1250 | 5.4188 | 0.0677 | 0.0313 | 5.3863 | 0.42° | 5.3512 | 0.0406 | 8-UN | 373 | ||

| 5 5/8 - 8 8-UN | 5.625 | 8 | 0.1250 | 5.5438 | 0.0677 | 0.0313 | 5.5113 | 0.41° | 5.4762 | 0.0406 | 8-UN | 378 | ||

| 5 3/4 - 8 8-UN | 5.75 | 8 | 0.1250 | 5.6688 | 0.0677 | 0.0313 | 5.6363 | 0.4° | 5.6012 | 0.0406 | 8-UN | 383 | ||

| 5 7/8 - 8 8-UN | 5.875 | 8 | 0.1250 | 5.7938 | 0.0677 | 0.0313 | 5.7613 | 0.39° | 5.7262 | 0.0406 | 8-UN | 388 | ||

| 6 - 8 8-UN | 6 | 8 | 0.1250 | 5.9188 | 0.0677 | 0.0313 | 5.8863 | 0.39° | 5.8512 | 0.0406 | 8-UN | 393 |

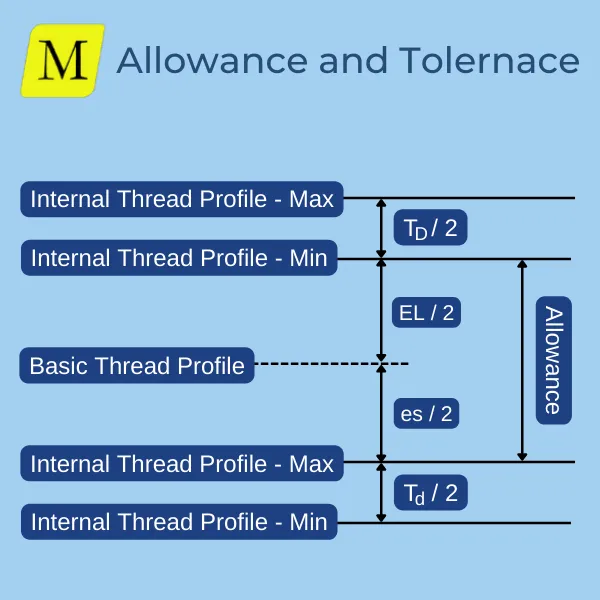

limits of Thread Dimensions (UNC, UNF & UNEF)

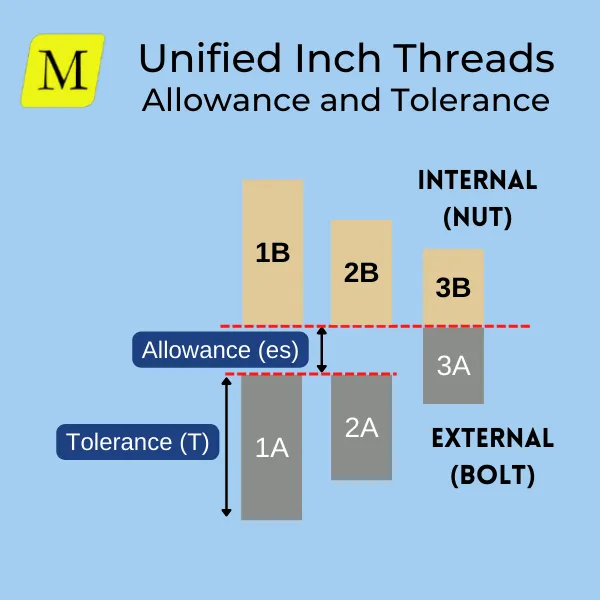

To manufacture or measure a thread, one has to know the maximum and minimum permissible values of the basic dimensions. These values are calculated according to the thread class (See below). To understand classes, you first need to understand the terms Allowance (Sometimes referred to as deviation) and Tolerances.

Definition of terms:

- Allowance (Deviation): The minimum permissible distance between the basic and actual profile.

- Tolerance: The width of the tolerance field of a diameter on the actual thread profile. (Pitch, Major & Minor diameters)

- A small allowance means that the assembly of a male and female thread will be harder, but after assembly, there will be less freedom of movement.

- A large allowance means that the assembly of a male and female thread will be easier, but after assembly, there will be more freedom of movement.

- The allowance size does not influence a thread’s production difficulty or price.

- A wide tolerance is easier and cheaper to produce but yields a larger spread between threads.

- A narrow tolerance is challenging to produce and more expensive but yields a smaller spread between threads.

Unified Thread Classes

- The class is defined by a two-character code.

- The first character defines is a digit between 1 and 3. 1=Loose fit, 2=Medium fit, and 3=Tight fit.

- The second character is a letter. A=External thread and B=Internal thread.

- In the Unified Inch thread system, only classes 1A & 2A have an allowance. The allowance for the two classes is the same.

- The other 4 classes have an allowance of Zero.

- All the internal thread profiles (B classes) have no allowance.

- Classes 1A & 1B: These classes are suitable for applications where a liberal tolerance and allowance are required to permit easy assembly. The maximum diameters of Class 1A threads are smaller than the basic diameter by the allowance amount. The minimum diameters of Class 1B threads are equal to the basic diameters and consequently afford no allowance at maximum material condition.

- Classes 2A & 2B: Classes 2A (external) and 2B (internal) are the default classes used for the commercial production of Nut, Bols, and otehr threaded fasteners. They are the default class unless otherwise specified. they have the same allowance as classes 1A/1B. However, they have a narrower tolerance field. The difficulty of assembly is the same, but the spread between different parts in a production batch is smaller.

- Classes 3A & 3B: These classes are suitable for applications where tight fit and accuracy of thread elements are essential. The maximum diameters of Class 3A threads and the minimum diameters of Class 3B threads are the same (Both have zero allowance). The accuracy is high, but the assembly is difficult.

- Combinations of Classes: The engineer can select any valid class for the male and female threads to achieve his design goals. The valid classes are defined in ASTM B1.1 as follows:

- Classes 2A, 2A, 3B, and 3B are always valid.

- Classes 1A & 1B are valid only for UNC threads with a nominal diameter equal to or larger than 1/4″.

Unified Thread Allowance.

The allowance es should be calculated for external threads with classes 1A and 2A. The allowance of both classes is the same and equals 0.3 times the pitch diameter tolerance of class 2A. It is the function of 3 parameters.

- D – Basic (nominal diameter)

- P – Pitch (1/TPI)

- LE – Length of engagement. If not explicitly specified, the length of engagement is assumed to be 5 pitches. (LE=5*P)

- All parameters are in inches

\begin{array} \large \,es& = 0.3 \times\,[\,0.0015 \times \sqrt[3]{D} &\\ & +\,0.0015 \times \sqrt{LE}&\\ & + 0.015 \times \sqrt[3]{P^{2}}\,] \end{array}

- The result should be rounded to 6 decimal places.

- ASTM B1.1 lists in a long chart the allowance for each thread size. However, the results of this formula are 100% accurate, and there is no need to browse the chart.

- You can use our Advanced Threading Calculator to obtain the allowance according to a thread description or use the mini-calculator below.