A short video explaining 10 basic thread terms in

Fundamental TriangleA triangle that defines the shape and dimensions of the basic thread profile. The corners of this triangle coincide with three consecutive intercepts of the extended flanks of the basic profile. Truncations at the thread crest and root are applied to this triangle to determine the final shape(...) Read More

Fundamental TriangleA triangle that defines the shape and dimensions of the basic thread profile. The corners of this triangle coincide with three consecutive intercepts of the extended flanks of the basic profile. Truncations at the thread crest and root are applied to this triangle to determine the final shape(...) Read More Height of Fundamental Triangle (Thread)Also called the height of sharp "V"). It is the distance measured between the apex and the base of the fundamental triangle of the thread profile Read More

Height of Fundamental Triangle (Thread)Also called the height of sharp "V"). It is the distance measured between the apex and the base of the fundamental triangle of the thread profile Read More L1 GageL1 is one of the most critical dimensions to control when manufacturing an NPT thread. The typical inspection method uses a RIng Gage for external threads and a Plug Gage for internal threads. When turning "Hand Tight" into the thread (do not force the gage), the step is required to be aligned(...) Read More

L1 GageL1 is one of the most critical dimensions to control when manufacturing an NPT thread. The typical inspection method uses a RIng Gage for external threads and a Plug Gage for internal threads. When turning "Hand Tight" into the thread (do not force the gage), the step is required to be aligned(...) Read More Lead Angle (Threads)This lead angle (φ) measures the inclination of a screw helix from a plane that is perpendicular to the screw's axis. In more simple words, it is the proportion of the lead of the screw relative to its diameter. Read More

Lead Angle (Threads)This lead angle (φ) measures the inclination of a screw helix from a plane that is perpendicular to the screw's axis. In more simple words, it is the proportion of the lead of the screw relative to its diameter. Read More Lead (Threading)The lead is the linear distance the thread travels due to a full 360° rotation. Read More

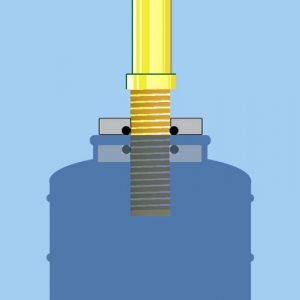

Lead (Threading)The lead is the linear distance the thread travels due to a full 360° rotation. Read More Length of EngagementLength of Engagement (LE) is the axial distance of full (360°) threads in contact between the male and female parts of a threading assembly. It is usually measured in multiples of the pitch. For example, 5P means a length of engagement of five times the pitch. Read More

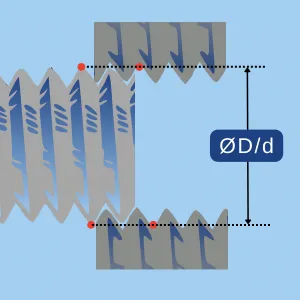

Length of EngagementLength of Engagement (LE) is the axial distance of full (360°) threads in contact between the male and female parts of a threading assembly. It is usually measured in multiples of the pitch. For example, 5P means a length of engagement of five times the pitch. Read More Major DiameterThe major diameter of a thread is the diameter of an imaginary cylinder that touches the largest diameter of a thread. The nominal value of the major diameter equals the nominal thread size. For example, in a UNC 1/4-20 thread, the nominal major diameter is 1/4" (6.35 mm) Read More

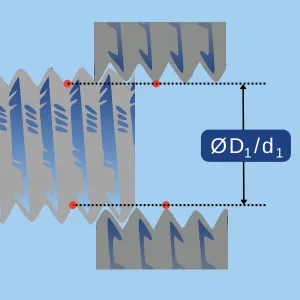

Major DiameterThe major diameter of a thread is the diameter of an imaginary cylinder that touches the largest diameter of a thread. The nominal value of the major diameter equals the nominal thread size. For example, in a UNC 1/4-20 thread, the nominal major diameter is 1/4" (6.35 mm) Read More Minor DiameterThe minor diameter is the diameter of an imaginary cylinder that touches the smallest diameter of a thread. It depends on the pitch and the thread's angle. Read More

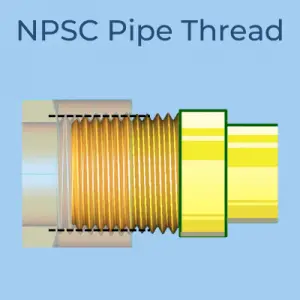

Minor DiameterThe minor diameter is the diameter of an imaginary cylinder that touches the smallest diameter of a thread. It depends on the pitch and the thread's angle. Read More NPSC Thread SeriesNPSC Internal Straight (parallel) Pipe Threads are used to manufacture pressure-tight fittings when assembled with an NPT external taper thread. This series applies to internal threads only. (The external thread is the standard NPT thread). Read More

NPSC Thread SeriesNPSC Internal Straight (parallel) Pipe Threads are used to manufacture pressure-tight fittings when assembled with an NPT external taper thread. This series applies to internal threads only. (The external thread is the standard NPT thread). Read More NPSF - Nation Pipe Straight Fuel ThreadNPSF is a complimentary thread series part of the Dryseal Pipe thread standard defined in ASTM B1.20.3. The typical dryseal thread is the NPTF, tapered thread. However, in some cases, it is desired to mate the external tapered NPTF thread with an internal straight thread. Read More

NPSF - Nation Pipe Straight Fuel ThreadNPSF is a complimentary thread series part of the Dryseal Pipe thread standard defined in ASTM B1.20.3. The typical dryseal thread is the NPTF, tapered thread. However, in some cases, it is desired to mate the external tapered NPTF thread with an internal straight thread. Read More NPSI - Nation Pipe Straight Intermediate ThreadNPSI is a complimentary thread series part of the Dryseal Pipe thread standard defined in ASTM B1.20.3. The typical dryseal thread is the NPTF, tapered thread. However, in some cases, it is desired to mate the external tapered NPTF thread with an internal straight thread. Read More

NPSI - Nation Pipe Straight Intermediate ThreadNPSI is a complimentary thread series part of the Dryseal Pipe thread standard defined in ASTM B1.20.3. The typical dryseal thread is the NPTF, tapered thread. However, in some cases, it is desired to mate the external tapered NPTF thread with an internal straight thread. Read More NPSL Thread SeriesThe NPSL thread series is designed to produce a pipe thread with the largest diameter possible to cut on a standard pipe. The internal and external thread dimensions are designed to have a "loose fit", and a locknut with an O-ring is required to create a seal. Read More

NPSL Thread SeriesThe NPSL thread series is designed to produce a pipe thread with the largest diameter possible to cut on a standard pipe. The internal and external thread dimensions are designed to have a "loose fit", and a locknut with an O-ring is required to create a seal. Read More NPSM Thread SeriesNPSM is a lesser-known pipe thread standard series defined in ASTM B1.20. This thread series creates a non-pressure tight connection. It is mainly used in mechanical joints and special applications with no internal pressure and, consequently, no sealing requirements. It is possible to achieve(...) Read More

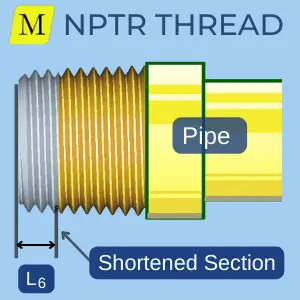

NPSM Thread SeriesNPSM is a lesser-known pipe thread standard series defined in ASTM B1.20. This thread series creates a non-pressure tight connection. It is mainly used in mechanical joints and special applications with no internal pressure and, consequently, no sealing requirements. It is possible to achieve(...) Read More NPTR Thread SeriesNPTR is a lesser-known pipe thread standard series defined in ASTM B1.20. This thread is used to connect Railing Joints that require a rigid mechanical connection, such as stair railings. Read More

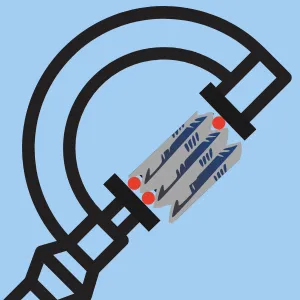

NPTR Thread SeriesNPTR is a lesser-known pipe thread standard series defined in ASTM B1.20. This thread is used to connect Railing Joints that require a rigid mechanical connection, such as stair railings. Read More Over Wire"Over Wire" is a nickname for a measuring method of the pitch diameter of threads. A wire with a known precise diameter is placed between the thread and the jaw of the micrometer. The value of diameter measured "over the wire" is used to calculate the pitch diameter of the thread. Read More

Over Wire"Over Wire" is a nickname for a measuring method of the pitch diameter of threads. A wire with a known precise diameter is placed between the thread and the jaw of the micrometer. The value of diameter measured "over the wire" is used to calculate the pitch diameter of the thread. Read More

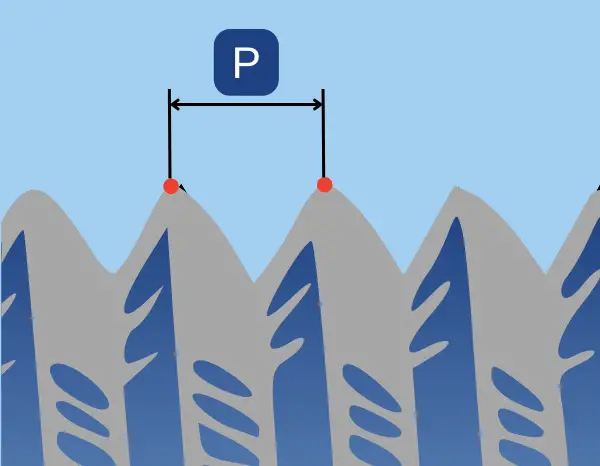

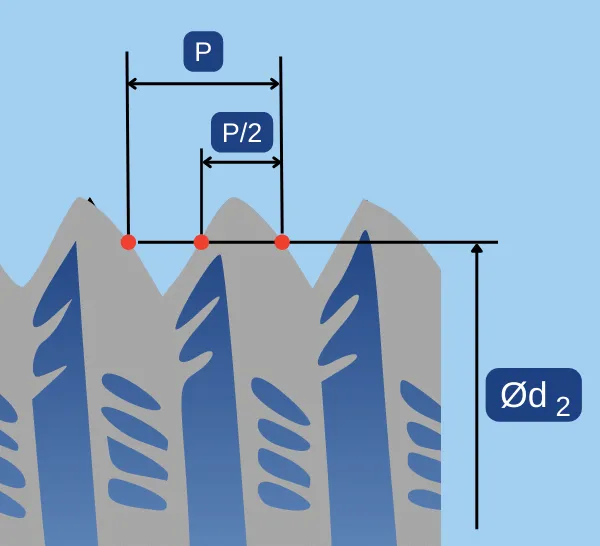

Pitch DiameterThe pitch diameter (also referred to as the effective diameter) is the diameter of an imaginary cylinder, which intersects it so that the distance between two intersection points at opposite flanks of a thread flanks equals half the nominal pitch of the thread. Read More

Pitch DiameterThe pitch diameter (also referred to as the effective diameter) is the diameter of an imaginary cylinder, which intersects it so that the distance between two intersection points at opposite flanks of a thread flanks equals half the nominal pitch of the thread. Read More Tap Drill SizeThe drill diameter to use in preparation for a tapping operation. Unless otherwise specified, it refers to 75% thread depth for a Tap Cutting tool. For more accurate data, it is recommended to use a Tap Drill Size Calculator that considers the tapping tool type and the required thread depth. Read More

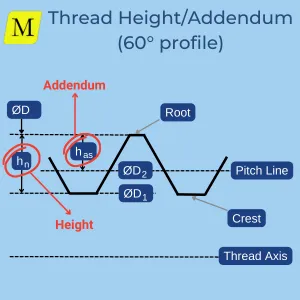

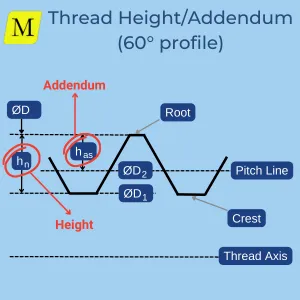

Tap Drill SizeThe drill diameter to use in preparation for a tapping operation. Unless otherwise specified, it refers to 75% thread depth for a Tap Cutting tool. For more accurate data, it is recommended to use a Tap Drill Size Calculator that considers the tapping tool type and the required thread depth. Read More Thread addendumThe distance between the crest and the pitch line in an external thread is called the thread addendum. It is designated with has. (Internal threads don't have an addendum). Read More

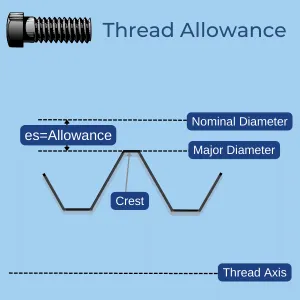

Thread addendumThe distance between the crest and the pitch line in an external thread is called the thread addendum. It is designated with has. (Internal threads don't have an addendum). Read More Thread Allowance (es)Thread allowance (es) is the distance in maximum material condition between the nominal thread diameter and the crest of an external thread. Read More

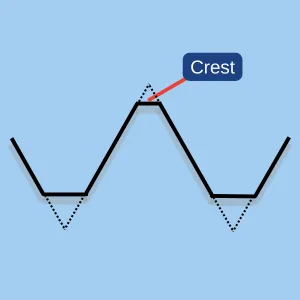

Thread Allowance (es)Thread allowance (es) is the distance in maximum material condition between the nominal thread diameter and the crest of an external thread. Read More Thread CrestThe crest is a flat (or rounded) surface connecting the flanks at the top of the thread grooves, whether internal or external. The crest width depends on the amount of tip truncation, which is defined by the specific thread standard. Read More

Thread CrestThe crest is a flat (or rounded) surface connecting the flanks at the top of the thread grooves, whether internal or external. The crest width depends on the amount of tip truncation, which is defined by the specific thread standard. Read More Thread Height (Depth)The distance between the crest and root is called the thread height. It is designated with hs for external threads and hn for Internal threads. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. Read More

Thread Height (Depth)The distance between the crest and root is called the thread height. It is designated with hs for external threads and hn for Internal threads. Because in all threads, either the crest or the root must be relieved, the height is a reference dimension and is usually not controlled. Read More Thread MillingThread milling refers to a metalworking process wherein a tool is rotated in a circular motion to cut interior and exterior threads of varying sizes. Thread pitch gets developed by axial movement in one revolution. Read More

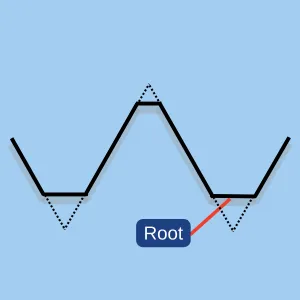

Thread MillingThread milling refers to a metalworking process wherein a tool is rotated in a circular motion to cut interior and exterior threads of varying sizes. Thread pitch gets developed by axial movement in one revolution. Read More Thread RootThe root is a flat (or rounded) surface connecting between the flanks at the bottom of the thread grooves, whether internal or external. The root width depends on the amount of tip truncation, which is defin Read More

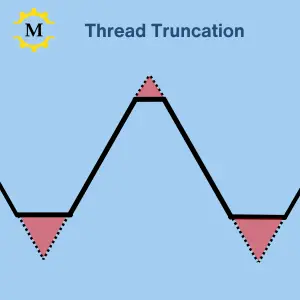

Thread RootThe root is a flat (or rounded) surface connecting between the flanks at the bottom of the thread grooves, whether internal or external. The root width depends on the amount of tip truncation, which is defin Read More Thread TruncationThread truncation refers to the removal of the sharp apex of the fundamental triangle. This truncation is measured perpendicular to the axis of the threads and can result in either a rounded or flat shape, depending on the thread standard. The amount of truncation determines the thread height.(...) Read More

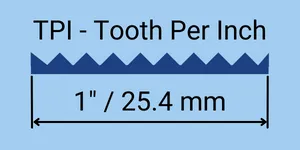

Thread TruncationThread truncation refers to the removal of the sharp apex of the fundamental triangle. This truncation is measured perpendicular to the axis of the threads and can result in either a rounded or flat shape, depending on the thread standard. The amount of truncation determines the thread height.(...) Read More Tooth per inch (tpi)TPI is an imperial unit of measurement for pitch, commonly used in the United States. As its name suggests, it is the number of times in which the feature appears over a linear distance of 1" (25.4 mm) Read More

Tooth per inch (tpi)TPI is an imperial unit of measurement for pitch, commonly used in the United States. As its name suggests, it is the number of times in which the feature appears over a linear distance of 1" (25.4 mm) Read More