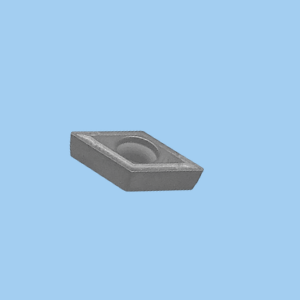

What is a Cermet insert?

Cermet is a cutting material combining ceramics and metals (usualט Nickel). The result is a harder substrate than carbide, therefore more wear-resistant, and enables machining at higher cutting speeds. The downside is very low toughness, and therefore, it is used only for finishing applications in stable conditions.

History of Cement Inserts

Cermet inserts were introduced in the 1950s. In those early days, Carbide inserts were not coated and the Ceremt inserts enabled machining at much higher cutting speeds. In the 1970s the first CVD coated carbide inserts were introduced in the market. The combination of a tungsten-carbide substrate with a thin layer of coating resulted in a product that could achieve a cutting speed not far from the Cermet with significantly higher toughness. Coated carbide inserts because the industry standard and Ceremt became a niche product. The use of Cermet inserts is still popular in the Japanese market and the Japanese carbide suppliers (Sumitomo, Tungaloy, Mitsubishi, Kyocera) offer a large selection of carbide grades. In the rest of the world, Cermet is rarely used.

When to use Cermet Inserts

- Cermet inserts offer a good solution for finishing applications in Turning and Grooving in stable conditions. In this situation, cutting speed can be about 10%-20% higher compared with CVD coated carbide grades (Such as Sandvik GC4305) and you will also get a better surface finish.

- Another niche is finish turning of sintered metals.

- In all other situations, it is better to stick with carbide.

Recommended Cermet Grades

*=Coated Cermet

| Brand | Super-Finish | Finish | Medium |

|---|---|---|---|

| Mitsubishi | AP25N* VP25N* | NX2525 AP25N* VP25N* | NX2525 AP25N* VP25N* NX3035 MP3025* |

| Sumitomo | T110A T1000A | T1200A T2000Z* T1500A T1500Z* | T1200A T2000Z* T1500A T1500Z* T2500A T3000Z* |

| Tungaloy | NS520 AT520* GT520* GT720* | NS520 NS730 GT730* NS9530 GT9530* | NS520 NS730 GT730* NS9530 GT9530* |

| Kyocera | TN30 TN610 PV710* PV30* TN6010 PV7010* | TN60 TN610 PV710* PV60* TN6010 PV7010* | TN60 PV60* TN620 PV720* TN6020 PV7020* PV7025* |

| Sandvik | CT5015 GC1525* | GC1525* | |

| Kennametal | KT315 KT125 | KT325 KT1120 KT5020* | |

| Iscar | IC20N IC520* | IC30N IC530N* | IC30N IC530N* |

| Seco | TP1020 TP1030* CM CMP* | TP1020 TP1030* |