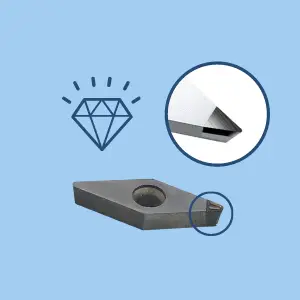

What is a PCD Insert ?

PCD stands for “Poly Crystalline Diamond”, the hardest available cutting material. PCD is a synthetic diamond produced by sintering together selected diamond particles with a metal matrix at high temperature and high pressure. The result is 90-95% diamond content material that reaches a hardness close to 6000 HV. In addition, the small amount of the binder gives the material additional toughness that makes it an efficient cutting material.

What are PCD inserts used for?

Although PCD has higher toughness than natural diamond, it still extremely brittle compared with other cutting materials. Because of that, PCD is used only to machine soft Non-Ferrous materials. The most popular material machined with PCD is Aluminum, followed by plastics and brass.

PCD inserts Vs other advanced Materials

| PROPERTY | CARBIDE | CERAMIC | CBN | PCD |

|---|---|---|---|---|

| Hardness [HV] | 1,300-1,800 | 2,100-2,400 | 4,500-5,000 | 5,000-6,000 |

| Price per Cutting Edge [USD] | 4$ | 10$ | 40$ | 160$ |

| Machining Hard Steel |

|

|

|

N/A |

| Machining Cast Iron |

|

|

|

N/A |

| Machining Super Alloys |

|

|

|

N/A |

| Machining Aluminum |

|

N/A | N/A |

|

Machining Aluminium with PCD inserts

Due to the high hardness, there is almost no limit to the cutting speed that can be applied, and in practice, the actual speed is limited by the RPM and stability. Although the price per cutting edge is 40 times higher than carbide, it is still cost-effective for mass production of Aluminium parts, especially in wheel production in the automotive industry.

Advantages:

- Excellent wear resistance.

- Excellent surface finish.

- Easier to keep close tolerances.

- Extremely high cutting speeds.

Disadvantages:

- Very high price.

- Very Brittle.