BSP is a British standard for pipe threads defined by ISO 7 & ISO 228. It is the most commonly used pipe thread system outside the USA. In North America, the more popular standard is NPT.

Although it is a British standard and the nominal pipe sizes are in Inches, the dimensions are defined in millimeters.

The Jargon, calculations, and charts defining BSP threads differ greatly from standard metric and inch threads. This webpage will explain the difference between the various series, how each parameter is defined, and show how to find the correct basic dimensions and tolerances for each thread.

Table of Contents

List of BSP Series

| Standard | Symbol | Description |

|---|---|---|

| ISO 7-1 |

Taper External (only) pipe thread with mechanical sealing on the thread (no need for O-rings). To be used with BSPT-Rc internal tapered threads or BSPT-Rp internal parallel threads. |

|

| ISO 7-1 |

Taper Internal (only) pipe thread with mechanical sealing on the thread (no need for O-rings). To be used with BSPT-R external threads. |

|

| ISO 7-1 |

Parallel Internal (only) pipe thread with mechanical sealing on the thread (no need for O-rings). To be used with BSPT-R external threads. |

|

| ISO 228-1 |

Parallel Internal & External threads that require an O-ring to achieve a seal. |

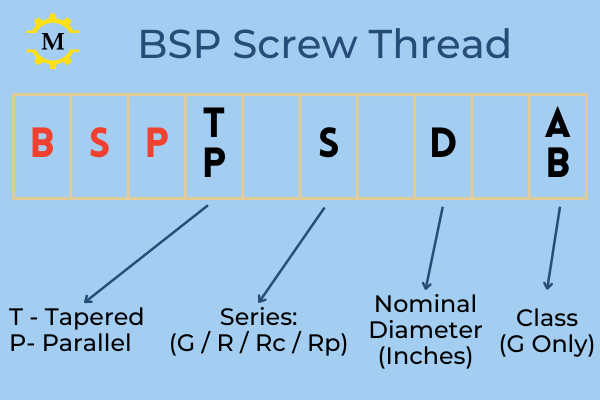

Designations of BSP Threads

BSPP – Parallel Thread.

- The series is always G.

- No Class – Internal Thread.

- Class B – Regular tolerance / Class A – Tight tolerance

BSPT – Tapered Thread.

- The series can be R, Rc, or Rp. See details in the above chart.

- T-type thread does not have a class.

- Diameter: The diameters are given in inch fractions. For example, 1/4″, 3/4″, 1 1/4″.

- Pitch: In BSP threads, the pitch is not included in the description.

BSP Designation Examples

| Designation | Nominal Diameter | Type | Internal / External | Tolerance |

|---|---|---|---|---|

| BSPP G 1/2 | 1/2" (12.7 mm) | Parallel | Internal | High |

| BSPP G 1/2 A | 1/2" (12.7 mm) | Parallel | External | Regular |

| BSPT R 3/4 | 3/4" (19.05 mm) | Tapered | External | Regular |

| BSPT Rc 3/4 | 3/4" (19.05 mm) | Tapered | Internal | Regular |

| BSPT Rp 3/4 | 3/4" (19.05 mm) | Tapered | Internal | Regular |

BSPT (Per ISO 7) – Tapered Pipe Thread

BSPT stands for British Standard Pipe Tapered. It is the common name of a group of threads defined by ISO 7-1 & ISO 7-2 standards. The formal definition in ISO-7 is “Pipe threads where pressure-tight joints are made on the threads”. In simple words, it means that the thread forms a mechanical seal without the aid of an O-ring or sealant. (Opposed to BSPP, which will be discussed in the next section).

The basic profile is a 55° truncated and rounded triangle, tapered at an angle of 1°47′ (1.79°) relative to the axis. The taper on BSPT threads allows them to form a seal when torqued as the flanks of the external and internal threads compress against each other (no clearance remains between the crests and roots of the threads because of the taper). Depending on the application, it can be used with or without a thread sealant.

Except for the nominal pipe thread, which is listed in Inch fractions, all the dimensions are defined in millimeters. Therefore all our below charts are in millimeters. You can view the Inch translation of all the dimensions in the BSP Thread Calculator

BSPT is divided into 3 sub-groups:

- BSPT R – External Tapered (Can be assembled with both Rc & Rp internal threads)

- BSPT Rc – Internal Tapered (To be used with BSPT R).

- BSPT Rp – Internal parallel (To be used with BSPT R).

Profile parameters (R, Rc &Rp)

The basic profile of the 3 sub-groups is identical. The only difference is that in R & Rc series, the profile is tilted by the tapered angle (relative to the thread axis).

BSPT Profile Drawing

Symbols

| Symbol | Name | Remark |

|---|---|---|

| P | Pitch | Given in TPI. When used in calculations it should be converted to distance: 25.4/TPI. |

| ß | Thread Tapper Angle |

|

| α | Thread V half Angle | Always 27.5° |

| H | Height of sharp V | H,h & r are multiples of the pitch. See the below formulas. |

| h | Thread Height | |

| r | Root/Crest Radius | |

| d / D | Major Diameter |

|

| d1 / D1 | Minor Diameter | |

| d2 / D2 | Pitch Diameter |

Formulas

- The thread charts define d and p. They are the same for the 3 sub-groups.

- α & ß are constant (See above chart).

- The rest of the common parameters can be calculated by the below formulas.

- The formulas are the same of d (external) and D (internal)

Additional parameters (R & Rp only)

Definition of parameters that are used for tapered threads

- Gauge Length: Because of the taper angle, the diameters (major, minor, and pitch) change as we move along the thread’s axis. The gauge length is an arbitrary distance from the thread’s end at which the measurements of diameters are made. This location may also be referred to as “Gauge Plane”. The thread standard also defines the tolerance for the gauge length.

- Useful Thread: A thread that is fully formed at the root but can be truncated at the crest by its intersection with the cylindrical surface of the product.

- Length: the distance from the thread’s end to the last useful thread.

- Washout (Vanished threads): The part of the thread which is not fully formed at the root

- Fitting Allowance: Length of useful thread beyond the gauge plane of an external thread required to provide for assembly with an internal thread at the upper limit of the tolerance. The fitting allowance is used to calculate the minimum required length for eternal and internal threads.

BSPT R (External)

BSPT Rc (Internal)

Symbols

| Symbol | Description | Remark |

|---|---|---|

| Lg | Gauge Length | The distance from the reference plane to the point where the diameters (Major, Minor, and pitch are measured) |

| T1 | Lg Tolerance -External | The tolerance can be defined by number of turns or distance |

| T2 | Lg Tolerance - Internal | |

| F | Fitting allowance | The length of useful threads beyond the gauge plane of an external thread required for proper assembly with an internal thread at the upper limit of the tolerance. |

| L | Overall Thread Length |

BSPT R (External Tapered) Dimensions Chart

- Dimensions are in millimeters. To view metric values, click the Thread Description.

- The below chart shows only the main dimensions. To view all the dimensions, click the thread description or use the BSPT Thread Calculator.

BSPT Rc (Internal Tapered) Dimensions Chart

- Dimensions are in millimeters. To view metric values, click the Thread Description.

- The below chart shows only the main dimensions. To view all the dimensions, click the thread description or use the BSPT Thread Calculator.

BSPT Rp (Internal Parallel) Dimensions Chart

- Dimensions are in millimeters. To view metric values, click the Thread Description.

- The below chart shows only the main dimensions. To view all the dimensions, click the thread description or use the BSPT Thread Calculator.

Tolerances and Inspection

The ISO 7-1 provides tolerances only for the following dimensions:

For tapered (Rc & Rc) threads:

- Gauge length

- Minimum thread length

For parallel Rp threads:

- Major diameter

- Pitch diameter

- Minor diameter

All the other dimensions are inspected by gauging. The tolerances for the gages are defined in ISO 7-2 and are outside the scope of this webpage.

BSPP (Per ISO 228) – Parallel Pipe Thread

BSPP stands for British Standard Pipe Parallel. It is the common name of a group of threads defined by ISO 228-1 & ISO 228-2 standards. The formal definition in ISO-228 is “Pipe threads where pressure-tight joints are not made on the threads”. In simple words, it means that the thread will not seal without the aid of an O-ring or sealant. (Opposed to BSPT, which was discussed above).

The basic profile is a 55° truncated and rounded triangle, identical to the BSPT Rp series thread. The only difference between the two is the tolerances on the Pitch, Major and Minor diameters.

BSPP G threads can have one of 3 classes:

- No class (For example, BSPP G 1/2): Indicates an internal thread.

- Class A (For example, BSPP G 1/2 A): Indicates an external high-precision thread.

- Class B (For instance, BSPP G 1/2 B): Indicates an external low-precision thread.

- The tolerance field width of class B is twice that of class A

Except for the nominal pipe thread, which is listed in Inch fractions, all the dimensions are defined in millimeters. Therefore all our below charts are in millimeters. You can view the Inch translation of all the dimensions in the BSP Thread Calculator

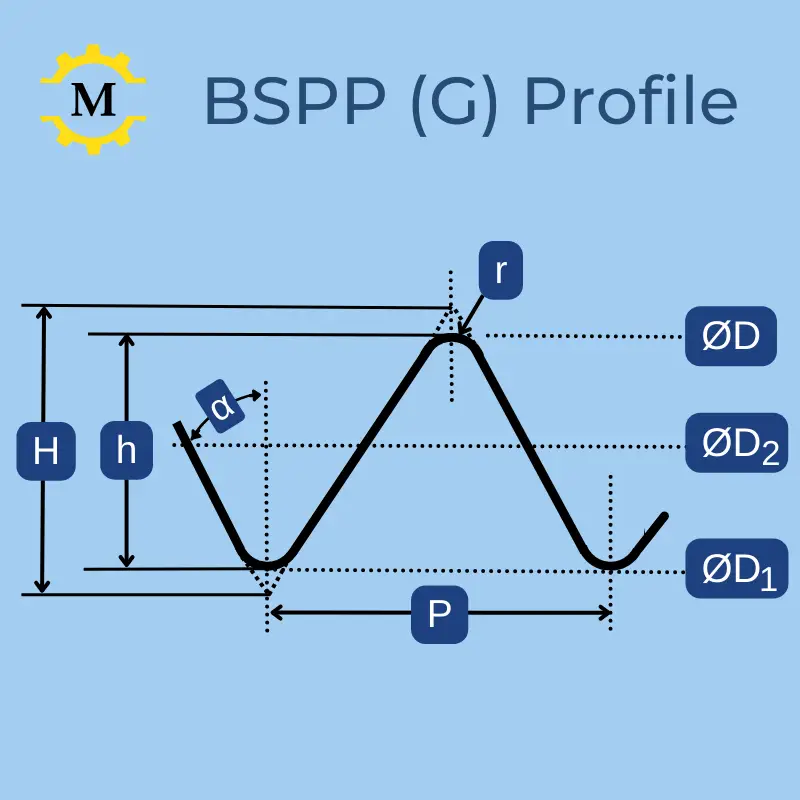

BSPP (G) – Drawing and parameters

BSPP (G) Profile Drawing

Symbols

| Symbol | Name |

|---|---|

| P | Pitch |

| α | Thread V half Angle |

| H | Height of Sharp V |

| h | Thread Height |

| r | Root/Crest Radius |

| d / D | Major Diameter |

| d1 / D1 | Minor Diameter |

| d2 / D2 | Pitch Diameter |

Formulas

BSPP (G) – Basic Dimensions Chart

These dimensions are the same for External and internal threads and for all classes. Check the tolerance section below for diametrical tolerances per the thread class.

- Dimensions are in millimeters. To view metric values, click the Thread Description.

- The below chart shows only the main dimensions. To view all the dimensions, click the thread description or use the BSPT Thread Calculator.

| Thread | Pipe OD | TPI | Pitch | Major Diameter | Pitch Diameter | Minor Diameter | Tap Drill Size |

|---|---|---|---|---|---|---|---|

| BSPP G 1/16 | 1/16" | 28 | 0.907 | 7.723 | 7.142 | 6.561 | 6.80 |

| BSPP G 1/8 | 1/8" | 28 | 0.907 | 9.728 | 9.147 | 8.566 | 8.80 |

| BSPP G 1/4 | 1/4" | 19 | 1.337 | 13.157 | 12.301 | 11.445 | 11.80 |

| BSPP G 3/8 | 3/8" | 19 | 1.337 | 16.662 | 15.806 | 14.950 | 15.30 |

| BSPP G 1/2 | 1/2" | 14 | 1.814 | 20.955 | 19.793 | 18.632 | 19.00 |

| BSPP G 5/8 | 5/8" | 14 | 1.814 | 22.911 | 21.749 | 20.588 | 21.00 |

| BSPP G 3/4 | 3/4" | 14 | 1.814 | 26.441 | 25.279 | 24.118 | 24.50 |

| BSPP G 7/8 | 7/8" | 14 | 1.814 | 30.201 | 29.039 | 27.878 | 28.50 |

| BSPP G 1 | 1" | 11 | 2.309 | 33.249 | 31.770 | 30.292 | 31.00 |

| BSPP G 1 1/8 | 1 1/8" | 11 | 2.309 | 37.897 | 36.418 | 34.940 | 35.30 |

| BSPP G 1 1/4 | 1 1/4" | 11 | 2.309 | 41.910 | 40.431 | 38.953 | 39.50 |

| BSPP G 1 1/2 | 1 1/2" | 11 | 2.309 | 47.803 | 46.324 | 44.846 | 45.50 |

| BSPP G 1 3/4 | 1 3/4" | 11 | 2.309 | 53.746 | 52.267 | 50.789 | 51.50 |

| BSPP G 2 | 2" | 11 | 2.309 | 59.614 | 58.135 | 56.657 | 57.50 |

| BSPP G 2 1/4 | 2 1/4" | 11 | 2.309 | 65.710 | 64.231 | 62.753 | -999.00 |

| BSPP G 2 1/2 | 2 1/2" | 11 | 2.309 | 75.184 | 73.705 | 72.227 | -999.00 |

| BSPP G 2 3/4 | 2 3/4" | 11 | 2.309 | 81.534 | 80.055 | 78.577 | -999.00 |

| BSPP G 3 | 3" | 11 | 2.309 | 87.884 | 86.405 | 84.927 | -999.00 |

| BSPP G 3 1/2 | 3 1/2" | 11 | 2.309 | 100.330 | 98.851 | 97.373 | -999.00 |

| BSPP G 4 | 4" | 11 | 2.309 | 113.030 | 111.551 | 110.073 | -999.00 |

| BSPP G 4 1/2 | 4 1/2" | 11 | 2.309 | 125.730 | 124.251 | 122.773 | -999.00 |

| BSPP G 5 | 5" | 11 | 2.309 | 138.430 | 136.951 | 135.473 | -999.00 |

| BSPP G 5 1/2 | 5 1/2" | 11 | 2.309 | 151.130 | 149.651 | 148.173 | -999.00 |

| BSPP G 6 | 6" | 11 | 2.309 | 163.830 | 162.351 | 160.873 | -999.00 |

BSPP (G) – Tolerances

ISO 228-1 provided only diametrical tolerancing. All the other thread parameters can be inspected only by gauging as detailed in ISO 228-2.