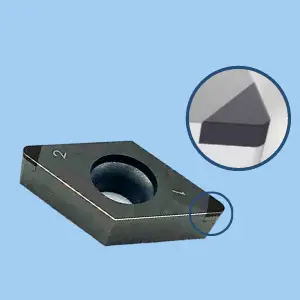

What is a CBN Insert (PCBN)?

PCBN (Nicknamed CBN) stands for “Polycrystalline Cubic Boron Nitride”, the second hardest material, second only to diamond. In addition to its high hardness[1] (4,500 HV[2]), it also has excellent hot hardness and chemical stability. Therefore, it can successfully machine Steel[3] up to 70 HRC[4] and other hard-to-machine materials.

What are CBN inserts used for?

- Machine Steel heat treated to 50-70 HRC. (Coated carbide inserts cannot machine materials above 45 HRC)

- Machine Cast Iron[5] 3 times faster compared with coated carbide inserts. (~ 1,500 mm/min, 5,00 SFM[6])

- Machine Titanium[7] and Inconel (HRSA[8]) 5 times faster compared with coated carbide (~350 mm/min, 1,100 SFM)

CBN inserts working materials and cutting speeds

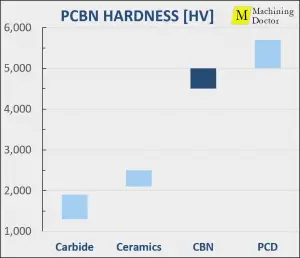

| PROPERTY | CARBIDE | CERAMIC | CBN | PCD |

|---|---|---|---|---|

| Hardness [HV] | 1,300-1,800 | 2,100-2,400 | 4,500-5,000 | 5,000-6,000 |

| Price per Cutting Edge [USD] | 4$ | 10$ | 40$ | 160$ |

| Machining Hard Steel |

|

|

|

N/A |

| Machining Cast Iron |

|

|

|

N/A |

| Machining Super Alloys |

|

|

|

N/A |

| Machining Aluminum |

|

N/A | N/A |

|

Machining Hardened Steel with CBN inserts

Advantages:

- Excellent wear resistance.

- Long tool-life

- High cutting speeds[6]

- Maintaining close tolerances.

- High surface finish[9]

- It can replace grinding in many applications.

Disadvantages:

- High price.

- Low depth of cut. The depth of cut is limited by the size of the brazed CBN tips.

- Solid CBN, which enables heavier machining, is far more expensive.

Machining Cast Iron with CBN inserts

The more popular solution for fast metal removal on Cast Iron is with Ceramic inserts[10]. Ceramic inserts cost less and can work in a higher depth of cuts. CBN inserts are used only for finishing operations that require higher surface finish and accuracy that cannot be obtained with Ceramic Inserts[10].

Machining Super Alloys (Nickel Based) with CBN inserts

The more popular solution for fast metal removal on Nickel Based Alloys is with Ceramic inserts. Ceramic inserts cost less and can work in a higher depth of cuts. CBN inserts are used only for finishing operations that require higher surface finish and accuracy that cannot be obtained with Ceramic Inserts.