Acme is a trapezoidal thread profile with a 29° V angle, defined in ASTM B1.5. It is the most popular thread used for traversing linear motion (For example, leadscrews and power screws) due to its ability to withstand large loads and ease of manufacturing. It is found in industrial equipment such as CNC machines and conveyors, but also in everyday-life equipment such as a jack, which we use to replace a flat tire.

Acme threads were first developed in the late 1800s by the American industrialist inventor William Sellers. Sellers aimed to create a leadscrew thread design that was stronger and easier to manufacture than the square thread design commonly used at the time. The resulting trapezoidal thread form became known as the Acme thread and quickly gained popularity in the design of leadscrews and power screws.

ACME – Table of Content

Easly obtain all the dimensions and tolerances with our Acme Thread Calculator

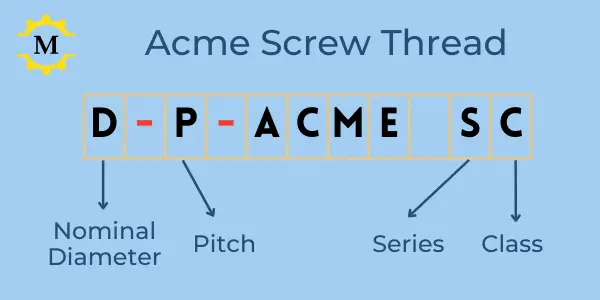

Designation

Basic designation syntax:

- Nominal Diameter in Inch Fraction

- Pitch in TPI

- Series: G – General / C – Centralized

- Class: 2, 3, or 4. Indicates the precision.

Diameter:

- The diameter can range between 1/4″ to 5″.

- It is also allowed to denote the diameters with a decimal value. For example, 0.250 (1/4″), 0.4375 (7/16″), etc.

Pitch:

- By default, the pitch is given in TPI. For example, 1/4-20 means a thread with a pitch of 20 TPI (1/20=0.05″).

- On multiple starts threads (see below), the pitch is indicated by distance. For example, 1/4-0.05P means a thread with a pitch of 0.05″ (same as 20 TPI).

Series:

- G – General use.

- C – Centralized. This class defines a more restricted clearance at the major diameter of both the internal and external screws that prevent wedging on the flanks.

Class:

- The class is defined by a number between 2 and 4.

- 2– Lower precision.

- 4 – Higher precision.

Internal and external designation is exactly the same. You cannot tell from the description alone if the thread is external or internal.

Additional Parameters:

- Direction: By default, the thread is right-hand. For a left-hand thread, add the suffix -LH.

- Number of Starts: By default, all threads have a single start. Thus the lead equals the pitch. For a multiple-start thread, the lead is also indicated by the letter L. For example, 1/4– 0.0625P – 0.1875L-ACMEdenotes an 0.25″ ACME thread with 3 starts. (0.1875/0.0625=3)

Designation Examples of Acme Threads

| Designation | Series |

Nominal Diameter |

TPI | Pitch | Lead | Class | Number of Starts | Thread Direction |

|---|---|---|---|---|---|---|---|---|

| 1/2-10-ACME 2G | G | 0.5" | 10 | 0.1" |

=Pitch |

2 | 1 | Right Hand |

| 0.5-10-ACME 4C | C | 0.5" | 10 | 0.1" |

=Pitch |

4 | 1 | Right Hand |

| 1/4– 0.0625P – 0.1875L-ACME 2G | G | 0.25" | 16 | 0.0625" | 0.1875" | 2 | 3 | Right Hand |

| 2.5-3-ACME 4C-LH | C | 2.5" | 3 | 0.3333" |

=Pitch |

4 | 1 | Left Hand |

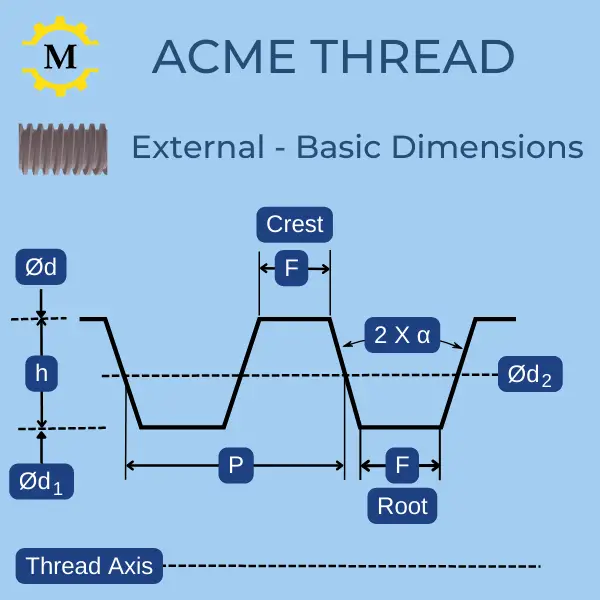

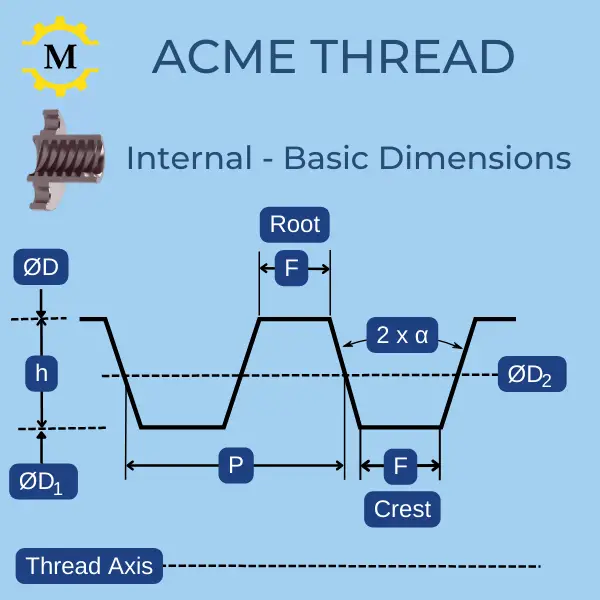

ACME Threads – Basic Dimensions

The basic dimensions are nominal dimensions of the ACME profile without allowances and tolerances (The series and class define that – see below). They are based on standard ASTM B1.5. The basic dimensions can be used for design. However, for manufacturing and machining, you need the allowable range of each dimension. This data can be found in the ASTM standard or in the Limits and Dimensions section below. All the basic dimensions are derived from simple formulas based on the thread’s nominal diameter and pitch.

Symbols

List of symbols used in charts and formulas of ACME Threads

| Symbol | Explanation |

|---|---|

| Basic Parameters - Diameters and Pitch | |

| D | Major (Basic) diameter of internal thread |

|

D1 |

Minor diameter of internal thread |

| D2 | Pitch diameter of internal thread |

| d | External Major Diameter |

| d1 | Minor diameter of external thread |

| d2 | Pitch diameter of external thread |

| n | Number of threds per Inch (TPI) |

| P | Pitch (Distance) |

| L | Lead |

| S | Number of Starts |

| h | Thread Height |

| F | Flat Width |

| LE | Length of Engagment |

| α | Thread V half Angle |

| Allowance, Deviation, and Tolerances | |

| TD |

Tolerance - Minor diameter of internal thread & (Major Diameter) |

| TD2 | Tolerance - Pitch diameter of internal thread |

| Td | Tolerance - Minor diameter of external thread & (Major Diameter) |

| Td2 | Tolerance - Minor diameter of external thread |

| es | Allowance - Pitch Diameter |

| EL | |

Formulas

External Thread

Internal thread

Dimensions Chart

Click the Thread Link to get the Full Thread Data for all classes in Inch and Metric units

* Click icon to show Additional columns.

(*) All dimensions are in Inches

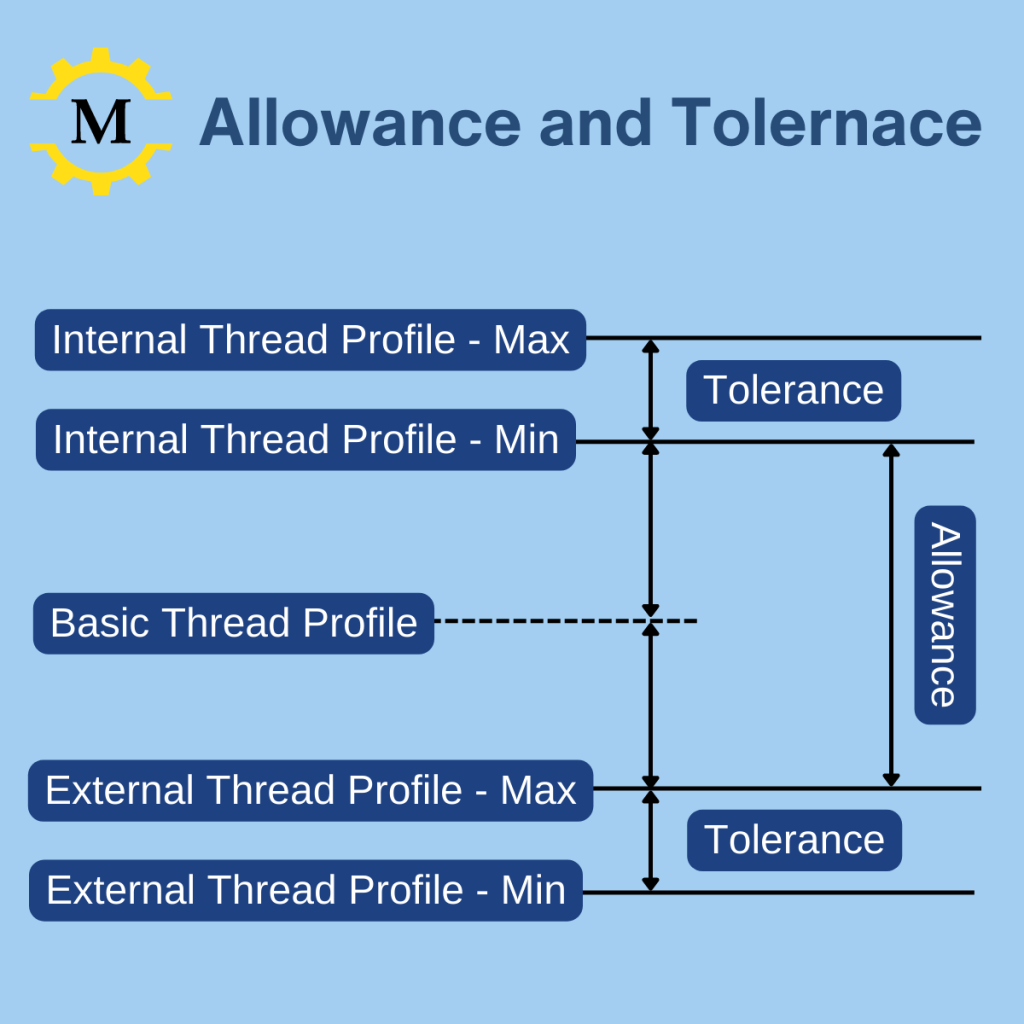

ACME Threads – Limits of Dimensions

To manufacture or measure a thread, one has to know the maximum and minimum permissible values of the basic dimensions. These values are calculated according to the thread series and class (See below).

Definition of terms:

- Allowance (Deviation): The minimum permissible distance between the basic and actual profile.

- Tolerance: The width of the tolerance field of a diameter on the actual thread profile. (Pitch, Major & Minor diameters)

- A small allowance means that the assembly of a male and female thread will be harder, but after assembly, there will be less freedom of movement.

- A large allowance means that the assembly of a male and female thread will be easier, but after assembly, there will be more freedom of movement.

- The allowance size does not influence a thread’s production difficulty or price.

- A wide tolerance is easier and cheaper to produce but yields a larger spread between threads.

- A narrow tolerance is challenging to produce and more expensive but yields a smaller spread between threads.

Series & Classes

ACME threads are divided into 3 series:

- G (General Purpose) – The most commonly used Acme threads.

- Wedging can occur under loads; therefore, it is recommended for applications where the screw and nut are supported individually.

- It has 3 precision classes 2G, 3G, and 4G.

- C (Centralized) – Tighter clearance between the internal and external threads. That prevents wedging on the flanks.

- More suitable for applications with higher load.

- It shares the exact basic dimensions of the C series. The difference is only in the tolerances.

- It has 3 precision classes 2C, 3C, and 4C.

- Stub – Compact threads with a 43% shorter stub height than standard Acme.

- Short and truncated thread profile, suitable for applications with limited space.

- Unlike G & C series, it only has a single precision class.

- They are defined in a separate ASTM document number B1.8.

Series G & C have 3 preciosn classes:

- 2G/2C – Least accurate and more commonly used.

- 3G/3C – Medium accuracy.

- 4G/4C – Highest accuracy, recommended to reduce backlash.

Limits Calculations

ASTM B1.5 defines how to calculate the tolerance of the following parameters:

- Major diameter (d / D)

- Minor diameter (d1 / D1)

- Pitch diameter (d2 / D2)

- Pitch & Lead (P / L)

- Angles between flanks (α)

The below formulas are not valid for the following cases:

- Centralizes Acme series.

- Engagement lengths that are larger than twice the major diameter.

- Threads with multiple starts.

- TPI values that are not one of 2-6, 8, 10, 12, 14, or 16.

- Nominal diameters that are not one of 1/4, 5/16, 3/8, 7/16, 1/2, 3/4, 7/8, 1, 1-1/8, 1-1/4, 1-3/8, 1-1/2, 1-3/4, 2, 2-1/2, 2-3/4, 3, 3-1/2, 4, 4-1/2, or 5 Inches.

For these cases, read the small print in ASTM B1.5 or use our Acme Thread Calculator that handles all cases!

Before calculating the limits, you need to obtain the following data:

- Allowance for major and minor diameters (el): Equals 0.002 for pitches of 10 TPI or coarser. For finer pitches, use 0.001.

- Allowance for pitch diameters (es): Should be obtained from ASM B1.5 (table 9). It cannot be calculated by a formula. You can either obtain it from the standard or use our below calculator.

- Pitch diameter tolerance (TD2): Should be obtained from ASM B1.5 (tables 5-7) or calculated with the below formula.

| Class | Kp | Kd |

|---|---|---|

| 2G / 3C | 0.03 | 0.006 |

| 3G / 3C | 0.014 | 0.0028 |

| 4G / 4C | 0.01 | 0.002 |

- Major diameter tolerance (Td): Equals to the TPI divided by 20. (But if less than 0.005, 0.005 should be used).

After the above data has been obtained, you can proceed with the below formulas to calculate the limits. The below formulas are valid for all cases (Including The limitation listed above).

Formulas for Limits of External Acme Thread

Formulas for Limits of an Internal Acme Thread

Special ACME Threads

Because of the nature of its use cases and the limited list of standard configurations, special Acme threads are commonly used.

What is considered a special Acme thread?

- A Diameter-Pitch combination that does not appear in this list.

- Multiple-Start threads.

- An engagement length that is larger than twice the major diameter.

The Acme Thread Calculator handles also Special Threads!

Diameter-Pitch combinations

The standard list of Acme threads in ASTM B1.5 has only one pitch option per diameter. However, “playing” with the pitch is an important design consideration since it allows us to increase the traverse speed by using a coarser pitch or increasing the accuracy by choosing a finer one. When opting for a special thread, ASTM B1.5 provides each pitch with the minimum and maximum allowed diameters.

Premisable Diamter-Pitch Combinations

- For s thread with an intermediate pitch value, use the diameters shown for the next coarser pitch in the graph.

- To get the dimensions for such a thread, follow the formulas provided above or our Acme Thread Calculator, which knows how to handle any diameter-pitch combination.

Multiple Start Threads

Multiple-Start Acme threads are popular since they can bump up the traverse speed in multiples of 2, 3, 4, or more.

The dimensions given in the standard are valid only for single-start threads. Use the below procedure to adjust the limits according to the number of starts.

- External threads (Screws) are not affected. The data for single-start threads should be used.

- For internal threads (Nuts), the allowance for major, minor, and pitch diameters is increased (relative to an equivalent single-start thread) by

K x es. K depends on the number of starts: for 2 starts k=0.5, 3 starts k=0.75, and for 4 starts or more, k=1. - Our Acme Thread Calculator also handles multiple-start threads!

Length of Engagement

Increasing the length of the engagement means using a lengthier nut that can support higher forces. The data listed in ASTM B1.5 and the formulas given above are valid for engagement lengths up to twice the major diameter. The pitch diameter allowance (es) should be increased by 0.1 x es x (LE - 2 x d) when LE>2XD. Our Acme Thread Calculator also handles all engagement lengths.