Table of Contents

List of Charts

* Easy access to all the data charts that appear on this page

- ISO standards

- List of Symbols

- Designation Examples

- Possible Diameter/Pitch combinations.

- Basic Dimensions

- Recommended Classes

- Allowance/Deviations (es/EL)

- Tolerances (Td/TD)

- Normal length of engagement

Overview

The ISO metric screw thread family is a series of general-use, 60° straight threads. It is the most commonly used worldwide thread system. It was one of the first topics standardized by the ISO committee as early as 1947 and is still used today.

ISO Standards

Several ISO standards define together the ISO metric thread system:

| ISO Standard | Topic | What’s Include? |

|---|---|---|

| ISO 261 | Possible Combinations | Lists in a chart all the possible Diameter/Pitch Combinations. Defines the Coase Pitch and Fine Pitch series. |

| ISO 68 | Basic Profile | Defines the basic profile of the thread including Pitch, Pitch Diameter, Heights, etc. A drawing with the above thread parameters. Formulas for the above parameters. |

| ISO 965-1 | Tolerances | The main document for ISO Metric Threads: * List and definition of symbols. * Tolerance classes definition. * Designation rules * Allowance Chart – Per class and pitch. * Normal Length of Engagement Chart – Per diameter and pitch. * Tolerance fields Charts – Per diameter and pitch. * Root radius Charts and formulas. * Recommended Tolerance classes – Charts per tolerance quality and length of engagement. * Formulas that were used to construct the charts. |

| ISO 965-2 | Limits | Charts for the allowed range of pitch, major and minor diameters for classes 6H and 6g. The values are calculated from the definitions of ISO 965-1. They have limited use since they provide data only for the default classes. |

Designations

The description always begins with a capital M, followed by the nominal thread diameter in millimeters. For example, M8 is a thread with a nominal diameter of 8 mm (0.315″). If no characters follow the M and diameter, it means that all the other parameters are according to the default as defined in ISO 965-1:

ISO Metric Thread Defaults:

- Pitch – According to the Coarse pitch series.

- Number of Starts – One.

- Class – 6g for external threads and 6H for internal threads. (Valid above 1.6 mm / 0.063″)

- Direction – Right-hand thread.

Metric thread designation Examples

- Cells with Golden Background – Values are derived from the above defaults.

- Cells with White Background – Values are derived from the description.

| Designation | Ø | Pitch | Internal / External | Lead | Number of Starts | Pitch Diameter Class | Major/ Minor Diameter Class | Thread Direction |

|---|---|---|---|---|---|---|---|---|

| M8 | 8 | 1.25 | Both | 1.25 | 1 | 6H/6g | 6H/6g | Right hand |

| M8 X 0.75 | 8 | 0.75 | Both | 0.75 | 1 | 6H/6g | 6H/6g | Right hand |

| M8 X Ph2.25P0.75 | 8 | 0.75 | Both | 2.25 | 3 | 6H/6g | 6H/6g | Right hand |

| M8 - 4g8e | 8 | 1.25 | External | 1.25 | 1 | 4g | 8e | Right hand |

| M8 X 0.75 - 5G | 8 | 0.75 | Internal | 1.25 | 1 | 5G | 5G | Right hand |

| M8 - RH | 8 | 1.25 | Both | 0.75 | 1 | 6H/6g | 6H/6g | Right hand |

| M8 Ph2.25P0.75 - 4g8e - LH | 8 | 0.75 | External | 2.25 | 3 | 4g | 8e | Left hand |

Explanation:

- Pitch: Designated by “X P“. For example, M8 X 0.75 means an 8 mm (0.315″) thread with a pitch of 0.75 mm (0.03″ or 34 TPI). If the “X P” is omitted, the pitch is defined by the Coase Pitch Series according to ISO-261.

- Number of starts: Designated by “Ph”. For example, M8 X Ph2.25P0.75. In this case, 2.25 mm is the lead, and 0.75 mm is the pitch. Ph must be a multiple of P since the number of starts equals Ph/P. For this example, the number of starts is 3. If Ph is omitted, the thread has a single start.

- Class: The class appears after the pitch. It is preceded by a “-” and consists of two or four characters. For example, M8 X 0.75 – 5g6g.

- Small letters represent external threads, while capital letters represent internal threads.

- Two charters long class mean that the class is valid for both the pitch and major/minor diameters.

- Four long charters mean a separate class for the pitch diameter (The first two characters) and major/minor diameter (The first two characters).

- For detailed explanations about classes, see the class section below.

- If the class is omitted, the default class is used. (See above table)

- Thread Direction: The direction appears after the class and is preceded by a “-“. If omitted, the direction is right-hand. If “- LH” appears, it designates a left-hand thread. For example, M8 X 0.75 – 5g6g – LH is a left-hand thread designation.

Standard ISO metric series

The ISO Metric Thread System consists of two series:

| Thread Series | From Diameter | To Diameter | Pitches Combinations per Diameter | Number of Combinations |

|---|---|---|---|---|

| 1 mm (0.04") | 68 mm (2.7") | 1 | 50 | |

| 1 mm (0.04") | 300 mm (11.8") | 1-5 | 118 |

Possible Combinations (Diameter/Pitch)

The below charts show all the possible thread size combinations of diameters/pitch as defined in ISO-261

- MC – Metric Coarse Thread Series

- MF – Metric Fine Thread Series

- Click to get the Full Thread Data-Sheet for a specific combination

Possible Combinations for M1 – M24

| Diameter | P=0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.75 | 0.8 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.5 | 3.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | MF | MC | ||||||||||||||||

| 1.1 | MF | MC | ||||||||||||||||

| 1.2 | MF | MC | ||||||||||||||||

| 1.4 | MF | MC | ||||||||||||||||

| 1.6 | MF | MC | ||||||||||||||||

| 1.8 | MF | MC | ||||||||||||||||

| 2 | MF | MC | ||||||||||||||||

| 2.2 | MF | MC | ||||||||||||||||

| 2.5 | MF | MC | ||||||||||||||||

| 3 | MF | MC | ||||||||||||||||

| 3.5 | MF | MC | ||||||||||||||||

| 4 | MF | MC | ||||||||||||||||

| 4.5 | MF | MC | ||||||||||||||||

| 5 | MF | MC | ||||||||||||||||

| 6 | MF | MC | ||||||||||||||||

| 7 | MF | MC | ||||||||||||||||

| 8 | MF | MF | MC | |||||||||||||||

| 9 | MF | MF | MC | |||||||||||||||

| 10 | MF | MF | MF | MC | ||||||||||||||

| 11 | MF | MF | MC | |||||||||||||||

| 12 | MF | MF | MF | MC | ||||||||||||||

| 14 | MF | MF | MF | MC | ||||||||||||||

| 16 | MF | MF | MC | |||||||||||||||

| 18 | MF | MF | MF | MC | ||||||||||||||

| 20 | MF | MF | MF | MC | ||||||||||||||

| 22 | MF | MF | MF | MC | ||||||||||||||

| 24 | MF | MF | MF | MC |

Possible Combinations for M27 – M300

| Diameter | P=1 | 1.25 | 1.5 | 1.75 | 2..0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 8.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 27 | MF | MF | MF | MC | ||||||||||

| 30 | MF | MF | MF | MF | MC | |||||||||

| 33 | MF | MF | MF | MC | ||||||||||

| 36 | MF | MF | MF | MC | ||||||||||

| 39 | MF | MF | MF | MC | ||||||||||

| 42 | MF | MF | MF | MF | MC | |||||||||

| 45 | MF | MF | MF | MF | MC | |||||||||

| 48 | MF | MF | MF | MF | MC | |||||||||

| 52 | MF | MF | MF | MF | MC | |||||||||

| 56 | MF | MF | MF | MF | MC | |||||||||

| 60 | MF | MF | MF | MF | MC | |||||||||

| 64 | MF | MF | MF | MF | MC | |||||||||

| 68 | MF | MF | MF | MF | MC | |||||||||

| 70 | MF | MF | MF | MF | MF | |||||||||

| 72 | MF | MF | MF | MF | MF | |||||||||

| 75 | MF | MF | MF | MF | MF | |||||||||

| 76 | MF | MF | MF | MF | MF | |||||||||

| 80 | MF | MF | MF | MF | MF | |||||||||

| 85 | MF | MF | MF | MF | ||||||||||

| 90 | MF | MF | MF | MF | ||||||||||

| 95 | MF | MF | MF | MF | ||||||||||

| 100 | MF | MF | MF | MF | ||||||||||

| 105 | MF | MF | MF | MF | ||||||||||

| 110 | MF | MF | MF | MF | ||||||||||

| 115 | MF | MF | MF | MF | ||||||||||

| 120 | MF | MF | MF | MF | ||||||||||

| 125 | MF | MF | MF | MF | MF | |||||||||

| 130 | MF | MF | MF | MF | MF | |||||||||

| 135 | MF | MF | MF | MF | ||||||||||

| 140 | MF | MF | MF | MF | MF | |||||||||

| 145 | MF | MF | MF | MF | ||||||||||

| 150 | MF | MF | MF | MF | MF | |||||||||

| 155 | MF | MF | MF | MF | ||||||||||

| 160 | MF | MF | MF | MF | ||||||||||

| 165 | MF | MF | MF | |||||||||||

| 170 | MF | MF | MF | MF | ||||||||||

| 175 | MF | MF | MF | |||||||||||

| 180 | MF | MF | MF | MF | ||||||||||

| 185 | MF | MF | MF | |||||||||||

| 190 | MF | MF | MF | MF | ||||||||||

| 195 | MF | MF | MF | |||||||||||

| 200 | MF | MF | MF | MF | ||||||||||

| 205 | MF | MF | MF | |||||||||||

| 210 | MF | MF | MF | MF | ||||||||||

| 220 | MF | MF | MF | MF | ||||||||||

| 230 | MF | MF | MF | MF | ||||||||||

| 240 | MF | MF | MF | MF | ||||||||||

| 250 | MF | MF | MF | MF | ||||||||||

| 260 | MF | MF | MF | |||||||||||

| 270 | MF | MF | MF | |||||||||||

| 280 | MF | MF | MF | |||||||||||

| 290 | MF | MF | MF | |||||||||||

| 300 | MF | MF | MF |

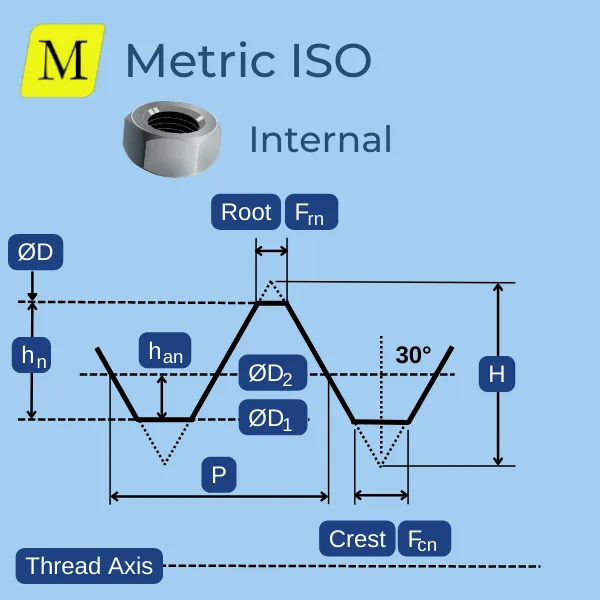

Basic Thread Dimensions

The basic dimensions are nominal dimensions of a metric thread profile without allowance and tolerances (The thread class defines that). They are based on standard ISO 68-1. The basic dimensions can be used for design. However, for manufacturing and machining, you need the allowable range of each dimension. This data can be found in ISO 951-1 or in the Limits and Dimensions section below. All these parameters are derived from simple formulas based on the thread’s nominal diameter and pitch.

Symbols

List of symbols used in charts and formulas of ISO Metric Threads

| Symbol | Explanation |

|---|---|

| Basic Parameters - Diameters and Pitch | |

| D | Major (Basic) diameter of internal thread |

|

D1 |

Minor diameter of internal thread |

| D2 | Pitch diameter of internal thread |

| d | Major (Basic) diameter of external thread |

| d1 | Minor diameter of external thread |

| d2 | Pitch diameter of external thread |

| d3 | Minor diameter for external thread root limits |

| P | Pitch |

| Ph | Lead |

| Height Parameters | |

| H | Height of fundamental triangle |

| hs | Thread Height - External Thread |

| has | Thread addendum - External Thread |

| hn | Thread Height - Internal Thread |

| hdn | Thread dedendum - Internal Thread |

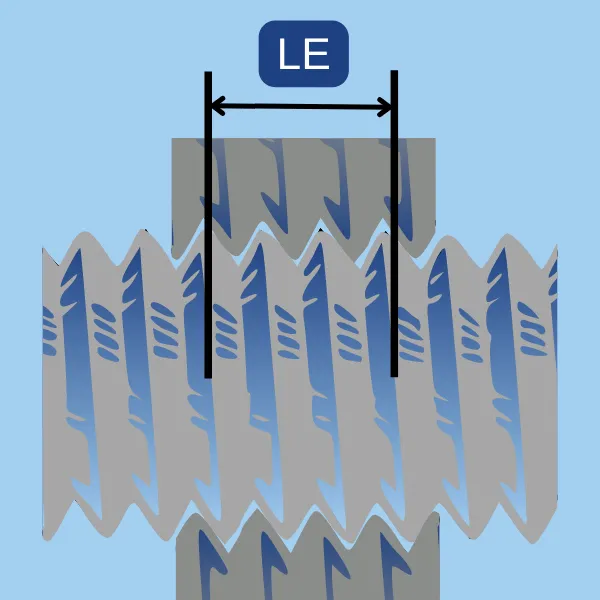

| Length Parameters | |

| LE | Length of Engagment |

| S / N / L | Designation for thread engagement group "Short" / "Medium" / "Long" |

| Allowance / Tolerance | |

| TD1 | Tolerance - D1 |

| TD2 | Tolerance - D2 |

| Td | Tolerance - d |

| Td2 | Tolerance - d2 |

| EI | Allowance - internal thread |

| es | Allowance - External Thread |

| Root / Crest | |

| R | Root radius - External Thread |

| C | Root truncation - External Thread |

| Fcs | Crest width - External Thread |

| Frs | Root width - External Thread |

| Fcs | Crest width - Internal Thread |

| Fcs | Root width - Internal Thread |

Formulas for basic dimensions

External Thread

\( \large P=\text{Pitch} \)

\( \large H=\frac{\sqrt{3}}{2}\times{P} = 0.866025404\times{P} \)

\( \large h_s=\frac{5}{8}\times{H} \)

\( \large h_{as}=\frac{3}{8}\times{H}\)

\( \large d_2=d-{2}\times{h_{as}} \)

\( \large d_1=d-{2}\times{h_s}\)

\( \large F_{cs}=\frac{P}{8}\)

\( \large F_{rs}=\frac{P}{4}\)

internal thread

\( \large P=\text{Pitch} \)

\( \large H=\frac{\sqrt{3}}{2}\times{P} = 0.866025404\times{P} \)

\( \large h_n=\frac{5}{8}\times{H} \)

\( \large h_{dn}=\frac{1}{4}\times{H}\)

\( \large D_1=D-{2}\times{h_n}\)

\( \large D_2=D1+{2}\times{h_{an}}\)

\( \large F_{rn}=\frac{P}{8}\)

\( \large F_{cn}=\frac{P}{4}\)

The above formulas provide the exact results. You case use them directly, utilize our Thread Calculator[ , or browse the below charts.

Metric thread Dimensions Charts

Basic Thread Dimensions – Metric Thread Coarse Pitch Series

Click the Thread Link to get the Full Thread Data for all Classes

* All dimensions are in mm. To view the Inch translation click the Thread Link

| Thread | Nominal Diameter | Pitch | Pitch Diameter | Minor Diameter | Thread Height | Cres/ Root | Tap Drill Size | Lead Angle | series | id |

|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 1 | 0.25 | 0.838 | 0.729 | 0.135 | 0.063 | 0.77 | 5.43 | MC | 1,000 |

| M1.1 | 1.1 | 0.25 | 0.938 | 0.829 | 0.135 | 0.063 | 0.87 | 4.85 | MC | 1,001 |

| M1.2 | 1.2 | 0.25 | 1.038 | 0.929 | 0.135 | 0.063 | 0.97 | 4.39 | MC | 1,002 |

| M1.4 | 1.4 | 0.3 | 1.205 | 1.075 | 0.162 | 0.075 | 1.13 | 4.53 | MC | 1,003 |

| M1.6 | 1.6 | 0.35 | 1.373 | 1.221 | 0.189 | 0.088 | 1.28 | 4.64 | MC | 1,004 |

| M1.8 | 1.8 | 0.35 | 1.573 | 1.421 | 0.189 | 0.088 | 1.48 | 4.05 | MC | 1,005 |

| M2 | 2 | 0.4 | 1.74 | 1.567 | 0.217 | 0.1 | 1.64 | 4.18 | MC | 1,006 |

| M2.2 | 2.2 | 0.45 | 1.908 | 1.713 | 0.244 | 0.113 | 1.79 | 4.29 | MC | 1,007 |

| M2.5 | 2.5 | 0.45 | 2.208 | 2.013 | 0.244 | 0.113 | 2.09 | 3.71 | MC | 1,008 |

| M3 | 3 | 0.5 | 2.675 | 2.459 | 0.271 | 0.125 | 2.55 | 3.4 | MC | 1,009 |

| M3.5 | 3.5 | 0.6 | 3.11 | 2.85 | 0.325 | 0.15 | 2.95 | 3.51 | MC | 1,010 |

| M4 | 4 | 0.7 | 3.545 | 3.242 | 0.379 | 0.175 | 3.36 | 3.6 | MC | 1,011 |

| M4.5 | 4.5 | 0.75 | 4.013 | 3.688 | 0.406 | 0.188 | 3.82 | 3.4 | MC | 1,012 |

| M5 | 5 | 0.8 | 4.48 | 4.134 | 0.433 | 0.2 | 4.27 | 3.25 | MC | 1,013 |

| M6 | 6 | 1 | 5.35 | 4.917 | 0.541 | 0.25 | 5.09 | 3.4 | MC | 1,015 |

| M7 | 7 | 1 | 6.35 | 5.917 | 0.541 | 0.25 | 6.09 | 2.87 | MC | 1,016 |

| M8 | 8 | 1.25 | 7.188 | 6.647 | 0.677 | 0.313 | 6.86 | 3.17 | MC | 1,017 |

| M9 | 9 | 1.25 | 8.188 | 7.647 | 0.677 | 0.313 | 7.86 | 2.78 | MC | 1,018 |

| M10 | 10 | 1.5 | 9.026 | 8.376 | 0.812 | 0.375 | 8.64 | 3.03 | MC | 1,019 |

| M11 | 11 | 1.5 | 10.026 | 9.376 | 0.812 | 0.375 | 9.64 | 2.73 | MC | 1,020 |

| M12 | 12 | 1.75 | 10.863 | 10.106 | 0.947 | 0.438 | 10.41 | 2.94 | MC | 1,021 |

| M14 | 14 | 2 | 12.701 | 11.835 | 1.083 | 0.5 | 12.18 | 2.87 | MC | 1,022 |

| M16 | 16 | 2 | 14.701 | 13.835 | 1.083 | 0.5 | 14.18 | 2.48 | MC | 1,024 |

| M18 | 18 | 2.5 | 16.376 | 15.294 | 1.353 | 0.625 | 15.73 | 2.78 | MC | 1,026 |

| M20 | 20 | 2.5 | 18.376 | 17.294 | 1.353 | 0.625 | 17.73 | 2.48 | MC | 1,027 |

| M22 | 22 | 2.5 | 20.376 | 19.294 | 1.353 | 0.625 | 19.73 | 2.24 | MC | 1,028 |

| M24 | 24 | 3 | 22.051 | 20.752 | 1.624 | 0.75 | 21.27 | 2.48 | MC | 1,029 |

| M27 | 27 | 3 | 25.051 | 23.752 | 1.624 | 0.75 | -99 | 2.18 | MC | 1,032 |

| M30 | 30 | 3.5 | 27.727 | 26.211 | 1.894 | 0.875 | -99 | 2.3 | MC | 1,034 |

| M33 | 33 | 3.5 | 30.727 | 29.211 | 1.894 | 0.875 | -99 | 2.08 | MC | 1,036 |

| M36 | 36 | 4 | 33.402 | 31.67 | 2.165 | 1 | -99 | 2.18 | MC | 1,038 |

| M39 | 39 | 4 | 36.402 | 34.67 | 2.165 | 1 | -99 | 2 | MC | 1,040 |

| M42 | 42 | 4.5 | 39.077 | 37.129 | 2.436 | 1.125 | -99 | 2.1 | MC | 1,042 |

| M45 | 45 | 4.5 | 42.077 | 40.129 | 2.436 | 1.125 | -99 | 1.95 | MC | 1,043 |

| M48 | 48 | 5 | 44.752 | 42.587 | 2.706 | 1.25 | -99 | 2.04 | MC | 1,044 |

| M52 | 52 | 5 | 48.752 | 46.587 | 2.706 | 1.25 | -99 | 1.87 | MC | 1,046 |

| M56 | 56 | 5.5 | 52.428 | 50.046 | 2.977 | 1.375 | -99 | 1.91 | MC | 1,048 |

| M60 | 60 | 5.5 | 56.428 | 54.046 | 2.977 | 1.375 | -99 | 1.78 | MC | 1,050 |

| M64 | 64 | 6 | 60.103 | 57.505 | 3.248 | 1.5 | -99 | 1.82 | MC | 1,052 |

| M68 | 68 | 6 | 64.103 | 61.505 | 3.248 | 1.5 | -99 | 1.71 | MC | 1,054 |

Basic Thread Dimensions – Metric Thread Fine Pitch Series

* All dimensions are in mm. To view Inch translation click the Thread Link

Click the Thread Link to get the Full Thread Data for all classes

* All dimensions are in mm. To view Inch translation click the Thread Link

| Thread | Nominal Diameter | Pitch | Pitch Diameter | Minor Diameter | Thread Height | Cres/ Root | Tap Drill Size | Lead Angle | series | id |

|---|---|---|---|---|---|---|---|---|---|---|

| M1 X 0.2 | 1 | 0.2 | 0.87 | 0.783 | 0.108 | 0.05 | 0.82 | 4.18 | MF | 2,000 |

| M1.1 X 0.2 | 1.1 | 0.2 | 0.97 | 0.883 | 0.108 | 0.05 | 0.92 | 3.75 | MF | 2,001 |

| M1.2 X 0.2 | 1.2 | 0.2 | 1.07 | 0.983 | 0.108 | 0.05 | 1.02 | 3.4 | MF | 2,002 |

| M1.4 X 0.2 | 1.4 | 0.2 | 1.27 | 1.183 | 0.108 | 0.05 | 1.22 | 2.87 | MF | 2,003 |

| M1.6 X 0.2 | 1.6 | 0.2 | 1.47 | 1.383 | 0.108 | 0.05 | 1.42 | 2.48 | MF | 2,004 |

| M1.8 X 0.2 | 1.8 | 0.2 | 1.67 | 1.583 | 0.108 | 0.05 | 1.62 | 2.18 | MF | 2,005 |

| M2 X 0.25 | 2 | 0.25 | 1.838 | 1.729 | 0.135 | 0.063 | 1.77 | 2.48 | MF | 2,006 |

| M2.2 X 0.25 | 2.2 | 0.25 | 2.038 | 1.929 | 0.135 | 0.063 | 1.97 | 2.24 | MF | 2,007 |

| M2.5 X 0.35 | 2.5 | 0.35 | 2.273 | 2.121 | 0.189 | 0.088 | 2.18 | 2.81 | MF | 2,008 |

| M3 X 0.35 | 3 | 0.35 | 2.773 | 2.621 | 0.189 | 0.088 | 2.68 | 2.3 | MF | 2,009 |

| M3.5 X 0.35 | 3.5 | 0.35 | 3.273 | 3.121 | 0.189 | 0.088 | 3.18 | 1.95 | MF | 2,010 |

| M4 X 0.5 | 4 | 0.5 | 3.675 | 3.459 | 0.271 | 0.125 | 3.55 | 2.48 | MF | 2,011 |

| M4.5 X 0.5 | 4.5 | 0.5 | 4.175 | 3.959 | 0.271 | 0.125 | 4.05 | 2.18 | MF | 2,012 |

| M5 X 0.5 | 5 | 0.5 | 4.675 | 4.459 | 0.271 | 0.125 | 4.55 | 1.95 | MF | 2,013 |

| M6 X 0.75 | 6 | 0.75 | 5.513 | 5.188 | 0.406 | 0.188 | 5.32 | 2.48 | MF | 2,014 |

| M7 X 0.75 | 7 | 0.75 | 6.513 | 6.188 | 0.406 | 0.188 | 6.32 | 2.1 | MF | 2,015 |

| M8 X 0.75 | 8 | 0.75 | 7.513 | 7.188 | 0.406 | 0.188 | 7.32 | 1.82 | MF | 2,017 |

| M8 X 1 | 8 | 1 | 7.35 | 6.917 | 0.541 | 0.25 | 7.09 | 2.48 | MF | 2,016 |

| M9 X 0.75 | 9 | 0.75 | 8.513 | 8.188 | 0.406 | 0.188 | 8.32 | 1.61 | MF | 2,019 |

| M9 X 1 | 9 | 1 | 8.35 | 7.917 | 0.541 | 0.25 | 8.09 | 2.18 | MF | 2,018 |

| M10 X 0.75 | 10 | 0.75 | 9.513 | 9.188 | 0.406 | 0.188 | 9.32 | 1.44 | MF | 2,022 |

| M10 X 1 | 10 | 1 | 9.35 | 8.917 | 0.541 | 0.25 | 9.09 | 1.95 | MF | 2,021 |

| M10 X 1.25 | 10 | 1.25 | 9.188 | 8.647 | 0.677 | 0.313 | 8.86 | 2.48 | MF | 2,020 |

| M11 X 0.75 | 11 | 0.75 | 10.513 | 10.188 | 0.406 | 0.188 | 10.32 | 1.3 | MF | 2,024 |

| M11 X 1 | 11 | 1 | 10.35 | 9.917 | 0.541 | 0.25 | 10.09 | 1.76 | MF | 2,023 |

| M12 X 1 | 12 | 1 | 11.35 | 10.917 | 0.541 | 0.25 | 11.09 | 1.61 | MF | 2,027 |

| M12 X 1.25 | 12 | 1.25 | 11.188 | 10.647 | 0.677 | 0.313 | 10.86 | 2.04 | MF | 2,026 |

| M12 X 1.5 | 12 | 1.5 | 11.026 | 10.376 | 0.812 | 0.375 | 10.64 | 2.48 | MF | 2,025 |

| M14 X 1 | 14 | 1 | 13.35 | 12.917 | 0.541 | 0.25 | 13.09 | 1.37 | MF | 2,030 |

| M14 X 1.25 | 14 | 1.25 | 13.188 | 12.647 | 0.677 | 0.313 | 12.86 | 1.73 | MF | 2,029 |

| M14 X 1.5 | 14 | 1.5 | 13.026 | 12.376 | 0.812 | 0.375 | 12.64 | 2.1 | MF | 2,028 |

| M16 X 1 | 16 | 1 | 15.35 | 14.917 | 0.541 | 0.25 | 15.09 | 1.19 | MF | 2,032 |

| M16 X 1.5 | 16 | 1.5 | 15.026 | 14.376 | 0.812 | 0.375 | 14.64 | 1.82 | MF | 2,031 |

| M18 X 1 | 18 | 1 | 17.35 | 16.917 | 0.541 | 0.25 | 17.09 | 1.05 | MF | 2,035 |

| M18 X 1.5 | 18 | 1.5 | 17.026 | 16.376 | 0.812 | 0.375 | 16.64 | 1.61 | MF | 2,034 |

| M18 X 2 | 18 | 2 | 16.701 | 15.835 | 1.083 | 0.5 | 16.18 | 2.18 | MF | 2,033 |

| M20 X 1 | 20 | 1 | 19.35 | 18.917 | 0.541 | 0.25 | 19.09 | 0.94 | MF | 2,038 |

| M20 X 1.5 | 20 | 1.5 | 19.026 | 18.376 | 0.812 | 0.375 | 18.64 | 1.44 | MF | 2,037 |

| M20 X 2 | 20 | 2 | 18.701 | 17.835 | 1.083 | 0.5 | 18.18 | 1.95 | MF | 2,036 |

| M22 X 1 | 22 | 1 | 21.35 | 20.917 | 0.541 | 0.25 | 21.09 | 0.85 | MF | 2,041 |

| M22 X 1.5 | 22 | 1.5 | 21.026 | 20.376 | 0.812 | 0.375 | 20.64 | 1.3 | MF | 2,040 |

| M22 X 2 | 22 | 2 | 20.701 | 19.835 | 1.083 | 0.5 | 20.18 | 1.76 | MF | 2,039 |

| M24 X 1 | 24 | 1 | 23.35 | 22.917 | 0.541 | 0.25 | 23.09 | 0.78 | MF | 2,044 |

| M24 X 1.5 | 24 | 1.5 | 23.026 | 22.376 | 0.812 | 0.375 | 22.64 | 1.19 | MF | 2,043 |

| M24 X 2 | 24 | 2 | 22.701 | 21.835 | 1.083 | 0.5 | 22.18 | 1.61 | MF | 2,042 |

| M27 X 1 | 27 | 1 | 26.35 | 25.917 | 0.541 | 0.25 | -99 | 0.69 | MF | 2,047 |

| M27 X 1.5 | 27 | 1.5 | 26.026 | 25.376 | 0.812 | 0.375 | -99 | 1.05 | MF | 2,046 |

| M27 X 2 | 27 | 2 | 25.701 | 24.835 | 1.083 | 0.5 | -99 | 1.42 | MF | 2,045 |

| M30 X 1 | 30 | 1 | 29.35 | 28.917 | 0.541 | 0.25 | -99 | 0.62 | MF | 2,051 |

| M30 X 1.5 | 30 | 1.5 | 29.026 | 28.376 | 0.812 | 0.375 | -99 | 0.94 | MF | 2,050 |

| M30 X 2 | 30 | 2 | 28.701 | 27.835 | 1.083 | 0.5 | -99 | 1.27 | MF | 2,049 |

| M30 X 3 | 30 | 3 | 28.051 | 26.752 | 1.624 | 0.75 | -99 | 1.95 | MF | 2,048 |

| M33 X 1.5 | 33 | 1.5 | 32.026 | 31.376 | 0.812 | 0.375 | -99 | 0.85 | MF | 2,054 |

| M33 X 2 | 33 | 2 | 31.701 | 30.835 | 1.083 | 0.5 | -99 | 1.15 | MF | 2,053 |

| M33 X 3 | 33 | 3 | 31.051 | 29.752 | 1.624 | 0.75 | -99 | 1.76 | MF | 2,052 |

| M36 X 1.5 | 36 | 1.5 | 35.026 | 34.376 | 0.812 | 0.375 | -99 | 0.78 | MF | 2,057 |

| M36 X 2 | 36 | 2 | 34.701 | 33.835 | 1.083 | 0.5 | -99 | 1.05 | MF | 2,056 |

| M36 X 3 | 36 | 3 | 34.051 | 32.752 | 1.624 | 0.75 | -99 | 1.61 | MF | 2,055 |

| M39 X 1.5 | 39 | 1.5 | 38.026 | 37.376 | 0.812 | 0.375 | -99 | 0.72 | MF | 2,060 |

| M39 X 2 | 39 | 2 | 37.701 | 36.835 | 1.083 | 0.5 | -99 | 0.97 | MF | 2,059 |

| M39 X 3 | 39 | 3 | 37.051 | 35.752 | 1.624 | 0.75 | -99 | 1.48 | MF | 2,058 |

| M42 X 1.5 | 42 | 1.5 | 41.026 | 40.376 | 0.812 | 0.375 | -99 | 0.67 | MF | 2,064 |

| M42 X 2 | 42 | 2 | 40.701 | 39.835 | 1.083 | 0.5 | -99 | 0.9 | MF | 2,063 |

| M42 X 3 | 42 | 3 | 40.051 | 38.752 | 1.624 | 0.75 | -99 | 1.37 | MF | 2,062 |

| M42 X 4 | 42 | 4 | 39.402 | 37.67 | 2.165 | 1 | -99 | 1.85 | MF | 2,061 |

| M45 X 1.5 | 45 | 1.5 | 44.026 | 43.376 | 0.812 | 0.375 | -99 | 0.62 | MF | 2,068 |

| M45 X 2 | 45 | 2 | 43.701 | 42.835 | 1.083 | 0.5 | -99 | 0.83 | MF | 2,067 |

| M45 X 3 | 45 | 3 | 43.051 | 41.752 | 1.624 | 0.75 | -99 | 1.27 | MF | 2,066 |

| M45 X 4 | 45 | 4 | 42.402 | 40.67 | 2.165 | 1 | -99 | 1.72 | MF | 2,065 |

| M48 X 1.5 | 48 | 1.5 | 47.026 | 46.376 | 0.812 | 0.375 | -99 | 0.58 | MF | 2,072 |

| M48 X 2 | 48 | 2 | 46.701 | 45.835 | 1.083 | 0.5 | -99 | 0.78 | MF | 2,071 |

| M48 X 3 | 48 | 3 | 46.051 | 44.752 | 1.624 | 0.75 | -99 | 1.19 | MF | 2,070 |

| M48 X 4 | 48 | 4 | 45.402 | 43.67 | 2.165 | 1 | -99 | 1.61 | MF | 2,069 |

| M52 X 1.5 | 52 | 1.5 | 51.026 | 50.376 | 0.812 | 0.375 | -99 | 0.54 | MF | 2,076 |

| M52 X 2 | 52 | 2 | 50.701 | 49.835 | 1.083 | 0.5 | -99 | 0.72 | MF | 2,075 |

| M52 X 3 | 52 | 3 | 50.051 | 48.752 | 1.624 | 0.75 | -99 | 1.09 | MF | 2,074 |

| M52 X 4 | 52 | 4 | 49.402 | 47.67 | 2.165 | 1 | -99 | 1.48 | MF | 2,073 |

| M56 X 1.5 | 56 | 1.5 | 55.026 | 54.376 | 0.812 | 0.375 | -99 | 0.5 | MF | 2,080 |

| M56 X 2 | 56 | 2 | 54.701 | 53.835 | 1.083 | 0.5 | -99 | 0.67 | MF | 2,079 |

| M56 X 3 | 56 | 3 | 54.051 | 52.752 | 1.624 | 0.75 | -99 | 1.01 | MF | 2,078 |

| M56 X 4 | 56 | 4 | 53.402 | 51.67 | 2.165 | 1 | -99 | 1.37 | MF | 2,077 |

| M60 X 1.5 | 60 | 1.5 | 59.026 | 58.376 | 0.812 | 0.375 | -99 | 0.46 | MF | 2,084 |

| M60 X 2 | 60 | 2 | 58.701 | 57.835 | 1.083 | 0.5 | -99 | 0.62 | MF | 2,083 |

| M60 X 3 | 60 | 3 | 58.051 | 56.752 | 1.624 | 0.75 | -99 | 0.94 | MF | 2,082 |

| M60 X 4 | 60 | 4 | 57.402 | 55.67 | 2.165 | 1 | -99 | 1.27 | MF | 2,081 |

| M64 X 1.5 | 64 | 1.5 | 63.026 | 62.376 | 0.812 | 0.375 | -99 | 0.43 | MF | 2,088 |

| M64 X 2 | 64 | 2 | 62.701 | 61.835 | 1.083 | 0.5 | -99 | 0.58 | MF | 2,087 |

| M64 X 3 | 64 | 3 | 62.051 | 60.752 | 1.624 | 0.75 | -99 | 0.88 | MF | 2,086 |

| M64 X 4 | 64 | 4 | 61.402 | 59.67 | 2.165 | 1 | -99 | 1.19 | MF | 2,085 |

| M68 X 1.5 | 68 | 1.5 | 67.026 | 66.376 | 0.812 | 0.375 | -99 | 0.41 | MF | 2,092 |

| M68 X 2 | 68 | 2 | 66.701 | 65.835 | 1.083 | 0.5 | -99 | 0.55 | MF | 2,091 |

| M68 X 3 | 68 | 3 | 66.051 | 64.752 | 1.624 | 0.75 | -99 | 0.83 | MF | 2,090 |

| M68 X 4 | 68 | 4 | 65.402 | 63.67 | 2.165 | 1 | -99 | 1.12 | MF | 2,089 |

| M70 X 1.5 | 70 | 1.5 | 69.026 | 68.376 | 0.812 | 0.375 | -99 | 0.4 | MF | 3,000 |

| M70 X 2 | 70 | 2 | 68.701 | 67.835 | 1.083 | 0.5 | -99 | 0.53 | MF | 3,001 |

| M70 X 3 | 70 | 3 | 68.051 | 66.752 | 1.624 | 0.75 | -99 | 0.8 | MF | 3,002 |

| M70 X 4 | 70 | 4 | 67.402 | 65.67 | 2.165 | 1 | -99 | 1.08 | MF | 3,003 |

| M70 X 6 | 70 | 6 | 66.103 | 63.505 | 3.248 | 1.5 | -99 | 1.65 | MF | 3,004 |

| M72 X 1.5 | 72 | 1.5 | 71.026 | 70.376 | 0.812 | 0.375 | -99 | 0.39 | MF | 3,005 |

| M72 X 2 | 72 | 2 | 70.701 | 69.835 | 1.083 | 0.5 | -99 | 0.52 | MF | 3,006 |

| M72 X 3 | 72 | 3 | 70.051 | 68.752 | 1.624 | 0.75 | -99 | 0.78 | MF | 3,007 |

| M72 X 4 | 72 | 4 | 69.402 | 67.67 | 2.165 | 1 | -99 | 1.05 | MF | 3,008 |

| M72 X 6 | 72 | 6 | 68.103 | 65.505 | 3.248 | 1.5 | -99 | 1.61 | MF | 3,009 |

| M75 X 1.5 | 75 | 1.5 | 74.026 | 73.376 | 0.812 | 0.375 | -99 | 0.37 | MF | 3,010 |

| M75 X 2 | 75 | 2 | 73.701 | 72.835 | 1.083 | 0.5 | -99 | 0.49 | MF | 3,011 |

| M75 X 3 | 75 | 3 | 73.051 | 71.752 | 1.624 | 0.75 | -99 | 0.75 | MF | 3,012 |

| M75 X 4 | 75 | 4 | 72.402 | 70.67 | 2.165 | 1 | -99 | 1.01 | MF | 3,013 |

| M75 X 6 | 75 | 6 | 71.103 | 68.505 | 3.248 | 1.5 | -99 | 1.54 | MF | 3,014 |

| M76 X 1.5 | 76 | 1.5 | 75.026 | 74.376 | 0.812 | 0.375 | -99 | 0.36 | MF | 3,015 |

| M76 X 2 | 76 | 2 | 74.701 | 73.835 | 1.083 | 0.5 | -99 | 0.49 | MF | 3,016 |

| M76 X 3 | 76 | 3 | 74.051 | 72.752 | 1.624 | 0.75 | -99 | 0.74 | MF | 3,017 |

| M76 X 4 | 76 | 4 | 73.402 | 71.67 | 2.165 | 1 | -99 | 0.99 | MF | 3,018 |

| M76 X 6 | 76 | 6 | 72.103 | 69.505 | 3.248 | 1.5 | -99 | 1.52 | MF | 3,019 |

| M80 X 1.5 | 80 | 1.5 | 79.026 | 78.376 | 0.812 | 0.375 | -99 | 0.35 | MF | 3,020 |

| M80 X 2 | 80 | 2 | 78.701 | 77.835 | 1.083 | 0.5 | -99 | 0.46 | MF | 3,021 |

| M80 X 3 | 80 | 3 | 78.051 | 76.752 | 1.624 | 0.75 | -99 | 0.7 | MF | 3,022 |

| M80 X 4 | 80 | 4 | 77.402 | 75.67 | 2.165 | 1 | -99 | 0.94 | MF | 3,023 |

| M80 X 6 | 80 | 6 | 76.103 | 73.505 | 3.248 | 1.5 | -99 | 1.44 | MF | 3,024 |

| M85 X 2 | 85 | 2 | 83.701 | 82.835 | 1.083 | 0.5 | -99 | 0.44 | MF | 3,025 |

| M85 X 3 | 85 | 3 | 83.051 | 81.752 | 1.624 | 0.75 | -99 | 0.66 | MF | 3,026 |

| M85 X 4 | 85 | 4 | 82.402 | 80.67 | 2.165 | 1 | -99 | 0.89 | MF | 3,027 |

| M85 X 6 | 85 | 6 | 81.103 | 78.505 | 3.248 | 1.5 | -99 | 1.35 | MF | 3,028 |

| M90 X 2 | 90 | 2 | 88.701 | 87.835 | 1.083 | 0.5 | -99 | 0.41 | MF | 3,029 |

| M90 X 3 | 90 | 3 | 88.051 | 86.752 | 1.624 | 0.75 | -99 | 0.62 | MF | 3,030 |

| M90 X 4 | 90 | 4 | 87.402 | 85.67 | 2.165 | 1 | -99 | 0.83 | MF | 3,031 |

| M90 X 6 | 90 | 6 | 86.103 | 83.505 | 3.248 | 1.5 | -99 | 1.27 | MF | 3,032 |

| M95 X 2 | 95 | 2 | 93.701 | 92.835 | 1.083 | 0.5 | -99 | 0.39 | MF | 3,033 |

| M95 X 3 | 95 | 3 | 93.051 | 91.752 | 1.624 | 0.75 | -99 | 0.59 | MF | 3,034 |

| M95 X 4 | 95 | 4 | 92.402 | 90.67 | 2.165 | 1 | -99 | 0.79 | MF | 3,035 |

| M95 X 6 | 95 | 6 | 91.103 | 88.505 | 3.248 | 1.5 | -99 | 1.2 | MF | 3,036 |

| M100 X 2 | 100 | 2 | 98.701 | 97.835 | 1.083 | 0.5 | -99 | 0.37 | MF | 3,037 |

| M100 X 3 | 100 | 3 | 98.051 | 96.752 | 1.624 | 0.75 | -99 | 0.56 | MF | 3,038 |

| M100 X 4 | 100 | 4 | 97.402 | 95.67 | 2.165 | 1 | -99 | 0.75 | MF | 3,039 |

| M100 X 6 | 100 | 6 | 96.103 | 93.505 | 3.248 | 1.5 | -99 | 1.14 | MF | 3,040 |

| M105 X 2 | 105 | 2 | 103.701 | 102.835 | 1.083 | 0.5 | -99 | 0.35 | MF | 3,041 |

| M105 X 3 | 105 | 3 | 103.051 | 101.752 | 1.624 | 0.75 | -99 | 0.53 | MF | 3,042 |

| M105 X 4 | 105 | 4 | 102.402 | 100.67 | 2.165 | 1 | -99 | 0.71 | MF | 3,043 |

| M105 X 6 | 105 | 6 | 101.103 | 98.505 | 3.248 | 1.5 | -99 | 1.08 | MF | 3,044 |

| M110 X 2 | 110 | 2 | 108.701 | 107.835 | 1.083 | 0.5 | -99 | 0.34 | MF | 3,045 |

| M110 X 3 | 110 | 3 | 108.051 | 106.752 | 1.624 | 0.75 | -99 | 0.51 | MF | 3,046 |

| M110 X 4 | 110 | 4 | 107.402 | 105.67 | 2.165 | 1 | -99 | 0.68 | MF | 3,047 |

| M110 X 6 | 110 | 6 | 106.103 | 103.505 | 3.248 | 1.5 | -99 | 1.03 | MF | 3,048 |

| M115 X 2 | 115 | 2 | 113.701 | 112.835 | 1.083 | 0.5 | -99 | 0.32 | MF | 3,049 |

| M115 X 3 | 115 | 3 | 113.051 | 111.752 | 1.624 | 0.75 | -99 | 0.48 | MF | 3,050 |

| M115 X 4 | 115 | 4 | 112.402 | 110.67 | 2.165 | 1 | -99 | 0.65 | MF | 3,051 |

| M115 X 6 | 115 | 6 | 111.103 | 108.505 | 3.248 | 1.5 | -99 | 0.98 | MF | 3,052 |

| M120 X 2 | 120 | 2 | 118.701 | 117.835 | 1.083 | 0.5 | -99 | 0.31 | MF | 3,053 |

| M120 X 3 | 120 | 3 | 118.051 | 116.752 | 1.624 | 0.75 | -99 | 0.46 | MF | 3,054 |

| M120 X 4 | 120 | 4 | 117.402 | 115.67 | 2.165 | 1 | -99 | 0.62 | MF | 3,055 |

| M120 X 6 | 120 | 6 | 116.103 | 113.505 | 3.248 | 1.5 | -99 | 0.94 | MF | 3,056 |

| M125 X 2 | 125 | 2 | 123.701 | 122.835 | 1.083 | 0.5 | -99 | 0.29 | MF | 3,057 |

| M125 X 3 | 125 | 3 | 123.051 | 121.752 | 1.624 | 0.75 | -99 | 0.44 | MF | 3,058 |

| M125 X 4 | 125 | 4 | 122.402 | 120.67 | 2.165 | 1 | -99 | 0.6 | MF | 3,059 |

| M125 X 6 | 125 | 6 | 121.103 | 118.505 | 3.248 | 1.5 | -99 | 0.9 | MF | 3,060 |

| M125 X 8 | 125 | 8 | 119.804 | 116.34 | 4.33 | 2 | -99 | 1.22 | MF | 3,061 |

| M130 X 2 | 130 | 2 | 128.701 | 127.835 | 1.083 | 0.5 | -99 | 0.28 | MF | 3,062 |

| M130 X 3 | 130 | 3 | 128.051 | 126.752 | 1.624 | 0.75 | -99 | 0.43 | MF | 3,063 |

| M130 X 4 | 130 | 4 | 127.402 | 125.67 | 2.165 | 1 | -99 | 0.57 | MF | 3,064 |

| M130 X 6 | 130 | 6 | 126.103 | 123.505 | 3.248 | 1.5 | -99 | 0.87 | MF | 3,065 |

| M130 X 8 | 130 | 8 | 124.804 | 121.34 | 4.33 | 2 | -99 | 1.17 | MF | 3,066 |

| M135 X 2 | 135 | 2 | 133.701 | 132.835 | 1.083 | 0.5 | -99 | 0.27 | MF | 3,067 |

| M135 X 3 | 135 | 3 | 133.051 | 131.752 | 1.624 | 0.75 | -99 | 0.41 | MF | 3,068 |

| M135 X 4 | 135 | 4 | 132.402 | 130.67 | 2.165 | 1 | -99 | 0.55 | MF | 3,069 |

| M135 X 6 | 135 | 6 | 131.103 | 128.505 | 3.248 | 1.5 | -99 | 0.83 | MF | 3,070 |

| M140 X 2 | 140 | 2 | 138.701 | 137.835 | 1.083 | 0.5 | -99 | 0.26 | MF | 3,071 |

| M140 X 3 | 140 | 3 | 138.051 | 136.752 | 1.624 | 0.75 | -99 | 0.4 | MF | 3,072 |

| M140 X 4 | 140 | 4 | 137.402 | 135.67 | 2.165 | 1 | -99 | 0.53 | MF | 3,073 |

| M140 X 6 | 140 | 6 | 136.103 | 133.505 | 3.248 | 1.5 | -99 | 0.8 | MF | 3,074 |

| M140 X 8 | 140 | 8 | 134.804 | 131.34 | 4.33 | 2 | -99 | 1.08 | MF | 3,075 |

| M145 X 2 | 145 | 2 | 143.701 | 142.835 | 1.083 | 0.5 | -99 | 0.25 | MF | 3,076 |

| M145 X 3 | 145 | 3 | 143.051 | 141.752 | 1.624 | 0.75 | -99 | 0.38 | MF | 3,077 |

| M145 X 4 | 145 | 4 | 142.402 | 140.67 | 2.165 | 1 | -99 | 0.51 | MF | 3,078 |

| M145 X 6 | 145 | 6 | 141.103 | 138.505 | 3.248 | 1.5 | -99 | 0.78 | MF | 3,079 |

| M150 X 2 | 150 | 2 | 148.701 | 147.835 | 1.083 | 0.5 | -99 | 0.25 | MF | 3,080 |

| M150 X 3 | 150 | 3 | 148.051 | 146.752 | 1.624 | 0.75 | -99 | 0.37 | MF | 3,081 |

| M150 X 4 | 150 | 4 | 147.402 | 145.67 | 2.165 | 1 | -99 | 0.49 | MF | 3,082 |

| M150 X 6 | 150 | 6 | 146.103 | 143.505 | 3.248 | 1.5 | -99 | 0.75 | MF | 3,083 |

| M150 X 8 | 150 | 8 | 144.804 | 141.34 | 4.33 | 2 | -99 | 1.01 | MF | 3,084 |

| M155 X 2 | 155 | 2 | 153.701 | 152.835 | 1.083 | 0.5 | -99 | 0.24 | MF | 3,085 |

| M155 X 3 | 155 | 3 | 153.051 | 151.752 | 1.624 | 0.75 | -99 | 0.36 | MF | 3,086 |

| M155 X 4 | 155 | 4 | 152.402 | 150.67 | 2.165 | 1 | -99 | 0.48 | MF | 3,087 |

| M155 X 6 | 155 | 6 | 151.103 | 148.505 | 3.248 | 1.5 | -99 | 0.72 | MF | 3,088 |

| M160 X 3 | 160 | 3 | 158.051 | 156.752 | 1.624 | 0.75 | -99 | 0.35 | MF | 3,089 |

| M160 X 4 | 160 | 4 | 157.402 | 155.67 | 2.165 | 1 | -99 | 0.46 | MF | 3,090 |

| M160 X 6 | 160 | 6 | 156.103 | 153.505 | 3.248 | 1.5 | -99 | 0.7 | MF | 3,091 |

| M160 X 8 | 160 | 8 | 154.804 | 151.34 | 4.33 | 2 | -99 | 0.94 | MF | 3,092 |

| M165 X 3 | 165 | 3 | 163.051 | 161.752 | 1.624 | 0.75 | -99 | 0.34 | MF | 3,093 |

| M165 X 4 | 165 | 4 | 162.402 | 160.67 | 2.165 | 1 | -99 | 0.45 | MF | 3,094 |

| M165 X 6 | 165 | 6 | 161.103 | 158.505 | 3.248 | 1.5 | -99 | 0.68 | MF | 3,095 |

| M170 X 3 | 170 | 3 | 168.051 | 166.752 | 1.624 | 0.75 | -99 | 0.33 | MF | 3,096 |

| M170 X 4 | 170 | 4 | 167.402 | 165.67 | 2.165 | 1 | -99 | 0.44 | MF | 3,097 |

| M170 X 6 | 170 | 6 | 166.103 | 163.505 | 3.248 | 1.5 | -99 | 0.66 | MF | 3,098 |

| M170 X 8 | 170 | 8 | 164.804 | 161.34 | 4.33 | 2 | -99 | 0.89 | MF | 3,099 |

| M175 X 3 | 175 | 3 | 173.051 | 171.752 | 1.624 | 0.75 | -99 | 0.32 | MF | 3,100 |

| M175 X 4 | 175 | 4 | 172.402 | 170.67 | 2.165 | 1 | -99 | 0.42 | MF | 3,101 |

| M175 X 6 | 175 | 6 | 171.103 | 168.505 | 3.248 | 1.5 | -99 | 0.64 | MF | 3,102 |

| M180 X 3 | 180 | 3 | 178.051 | 176.752 | 1.624 | 0.75 | -99 | 0.31 | MF | 3,103 |

| M180 X 4 | 180 | 4 | 177.402 | 175.67 | 2.165 | 1 | -99 | 0.41 | MF | 3,104 |

| M180 X 6 | 180 | 6 | 176.103 | 173.505 | 3.248 | 1.5 | -99 | 0.62 | MF | 3,105 |

| M180 X 8 | 180 | 8 | 174.804 | 171.34 | 4.33 | 2 | -99 | 0.83 | MF | 3,106 |

| M185 X 3 | 185 | 3 | 183.051 | 181.752 | 1.624 | 0.75 | -99 | 0.3 | MF | 3,107 |

| M185 X 4 | 185 | 4 | 182.402 | 180.67 | 2.165 | 1 | -99 | 0.4 | MF | 3,108 |

| M185 X 6 | 185 | 6 | 181.103 | 178.505 | 3.248 | 1.5 | -99 | 0.6 | MF | 3,109 |

| M190 X 3 | 190 | 3 | 188.051 | 186.752 | 1.624 | 0.75 | -99 | 0.29 | MF | 3,110 |

| M190 X 4 | 190 | 4 | 187.402 | 185.67 | 2.165 | 1 | -99 | 0.39 | MF | 3,111 |

| M190 X 6 | 190 | 6 | 186.103 | 183.505 | 3.248 | 1.5 | -99 | 0.59 | MF | 3,112 |

| M190 X 8 | 190 | 8 | 184.804 | 181.34 | 4.33 | 2 | -99 | 0.79 | MF | 3,113 |

| M195 X 3 | 195 | 3 | 193.051 | 191.752 | 1.624 | 0.75 | -99 | 0.28 | MF | 3,114 |

| M195 X 4 | 195 | 4 | 192.402 | 190.67 | 2.165 | 1 | -99 | 0.38 | MF | 3,115 |

| M195 X 6 | 195 | 6 | 191.103 | 188.505 | 3.248 | 1.5 | -99 | 0.57 | MF | 3,116 |

| M200 X 3 | 200 | 3 | 198.051 | 196.752 | 1.624 | 0.75 | -99 | 0.28 | MF | 3,117 |

| M200 X 4 | 200 | 4 | 197.402 | 195.67 | 2.165 | 1 | -99 | 0.37 | MF | 3,118 |

| M200 X 6 | 200 | 6 | 196.103 | 193.505 | 3.248 | 1.5 | -99 | 0.56 | MF | 3,119 |

| M200 X 8 | 200 | 8 | 194.804 | 191.34 | 4.33 | 2 | -99 | 0.75 | MF | 3,120 |

| M205 X 3 | 205 | 3 | 203.051 | 201.752 | 1.624 | 0.75 | -99 | 0.27 | MF | 3,121 |

| M205 X 4 | 205 | 4 | 202.402 | 200.67 | 2.165 | 1 | -99 | 0.36 | MF | 3,122 |

| M205 X 6 | 205 | 6 | 201.103 | 198.505 | 3.248 | 1.5 | -99 | 0.54 | MF | 3,123 |

| M210 X 3 | 210 | 3 | 208.051 | 206.752 | 1.624 | 0.75 | -99 | 0.26 | MF | 2,095 |

| M210 X 4 | 210 | 4 | 207.402 | 205.67 | 2.165 | 1 | -99 | 0.35 | MF | 2,094 |

| M210 X 6 | 210 | 6 | 206.103 | 203.505 | 3.248 | 1.5 | -99 | 0.53 | MF | 2,093 |

| M210 X 8 | 210 | 8 | 204.804 | 201.34 | 4.33 | 2 | -99 | 0.71 | MF | 1,087 |

| M220 X 3 | 220 | 3 | 218.051 | 216.752 | 1.624 | 0.75 | -99 | 0.25 | MF | 2,098 |

| M220 X 4 | 220 | 4 | 217.402 | 215.67 | 2.165 | 1 | -99 | 0.34 | MF | 2,097 |

| M220 X 6 | 220 | 6 | 216.103 | 213.505 | 3.248 | 1.5 | -99 | 0.51 | MF | 2,096 |

| M220 X 8 | 220 | 8 | 214.804 | 211.34 | 4.33 | 2 | -99 | 0.68 | MF | 1,089 |

| M230 X 3 | 230 | 3 | 228.051 | 226.752 | 1.624 | 0.75 | -99 | 0.24 | MF | 2,101 |

| M230 X 4 | 230 | 4 | 227.402 | 225.67 | 2.165 | 1 | -99 | 0.32 | MF | 2,100 |

| M230 X 6 | 230 | 6 | 226.103 | 223.505 | 3.248 | 1.5 | -99 | 0.48 | MF | 2,099 |

| M230 X 8 | 230 | 8 | 224.804 | 221.34 | 4.33 | 2 | -99 | 0.65 | MF | 1,091 |

| M240 X 3 | 240 | 3 | 238.051 | 236.752 | 1.624 | 0.75 | -99 | 0.23 | MF | 2,104 |

| M240 X 4 | 240 | 4 | 237.402 | 235.67 | 2.165 | 1 | -99 | 0.31 | MF | 2,103 |

| M240 X 6 | 240 | 6 | 236.103 | 233.505 | 3.248 | 1.5 | -99 | 0.46 | MF | 2,102 |

| M240 X 8 | 240 | 8 | 234.804 | 231.34 | 4.33 | 2 | -99 | 0.62 | MF | 1,093 |

| M250 X 3 | 250 | 3 | 248.051 | 246.752 | 1.624 | 0.75 | -99 | 0.22 | MF | 2,107 |

| M250 X 4 | 250 | 4 | 247.402 | 245.67 | 2.165 | 1 | -99 | 0.29 | MF | 2,106 |

| M250 X 6 | 250 | 6 | 246.103 | 243.505 | 3.248 | 1.5 | -99 | 0.44 | MF | 2,105 |

| M250 X 8 | 250 | 8 | 244.804 | 241.34 | 4.33 | 2 | -99 | 0.6 | MF | 1,095 |

| M260 X 4 | 260 | 4 | 257.402 | 255.67 | 2.165 | 1 | -99 | 0.28 | MF | 2,109 |

| M260 X 6 | 260 | 6 | 256.103 | 253.505 | 3.248 | 1.5 | -99 | 0.43 | MF | 2,108 |

| M260 X 8 | 260 | 8 | 254.804 | 251.34 | 4.33 | 2 | -99 | 0.57 | MF | 1,097 |

| M270 X 4 | 270 | 4 | 267.402 | 265.67 | 2.165 | 1 | -99 | 0.27 | MF | 2,111 |

| M270 X 6 | 270 | 6 | 266.103 | 263.505 | 3.248 | 1.5 | -99 | 0.41 | MF | 2,110 |

| M270 X 8 | 270 | 8 | 264.804 | 261.34 | 4.33 | 2 | -99 | 0.55 | MF | 1,099 |

| M280 X 4 | 280 | 4 | 277.402 | 275.67 | 2.165 | 1 | -99 | 0.26 | MF | 2,113 |

| M280 X 6 | 280 | 6 | 276.103 | 273.505 | 3.248 | 1.5 | -99 | 0.4 | MF | 2,112 |

| M280 X 8 | 280 | 8 | 274.804 | 271.34 | 4.33 | 2 | -99 | 0.53 | MF | 1,101 |

| M290 X 4 | 290 | 4 | 287.402 | 285.67 | 2.165 | 1 | -99 | 0.25 | MF | 2,115 |

| M290 X 6 | 290 | 6 | 286.103 | 283.505 | 3.248 | 1.5 | -99 | 0.38 | MF | 2,114 |

| M290 X 8 | 290 | 8 | 284.804 | 281.34 | 4.33 | 2 | -99 | 0.51 | MF | 1,103 |

| M300 X 4 | 300 | 4 | 297.402 | 295.67 | 2.165 | 1 | -99 | 0.25 | MF | 2,117 |

| M300 X 6 | 300 | 6 | 296.103 | 293.505 | 3.248 | 1.5 | -99 | 0.37 | MF | 2,116 |

| M300 X 8 | 300 | 8 | 294.804 | 291.34 | 4.33 | 2 | -99 | 0.49 | MF | 1,105 |

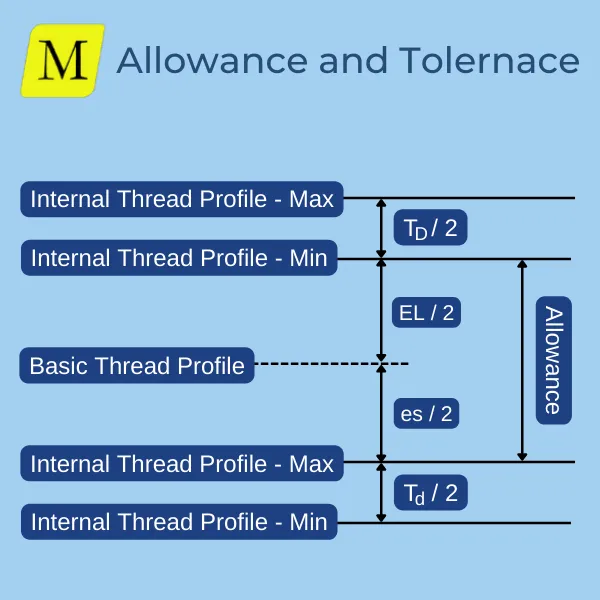

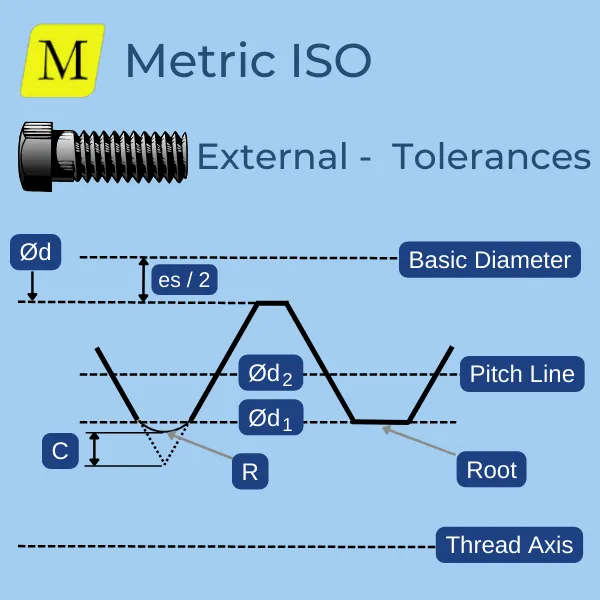

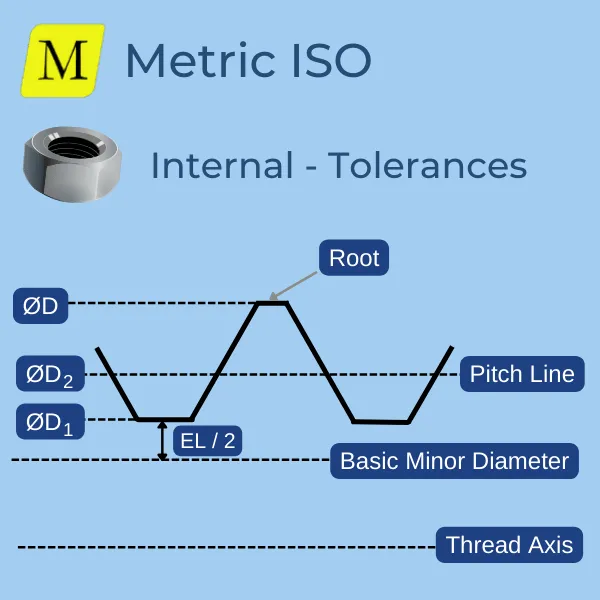

limits of Thread Dimensions

To manufacture or measure a thread, one has to know the maximum and minimum permissible values of the basic dimensions. These values are calculated according to the thread class (See below). To understand classes, you first need to understand the terms Allowance (Sometimes referred to as deviation) and Tolerances. The below data and explanations are based on ISO 965-1

Definition of terms:

- Allowance (Deviation): The minimum permissible distance between the basic and actual profile.

- Tolerance: The width of the tolerance field of a diameter on the actual thread profile. (Pitch, Major & Minor diameters)

- A small allowance means that the assembly of a male and female thread will be harder, but after assembly, there will be less freedom of movement.

- A large allowance means that the assembly of a male and female thread will be easier, but after assembly, there will be more freedom of movement.

- The allowance size does not influence a thread’s production difficulty or price.

- A wide tolerance is easier and cheaper to produce but yields a larger spread between threads.

- A narrow tolerance is challenging to produce and more expensive but yields a smaller spread between threads.

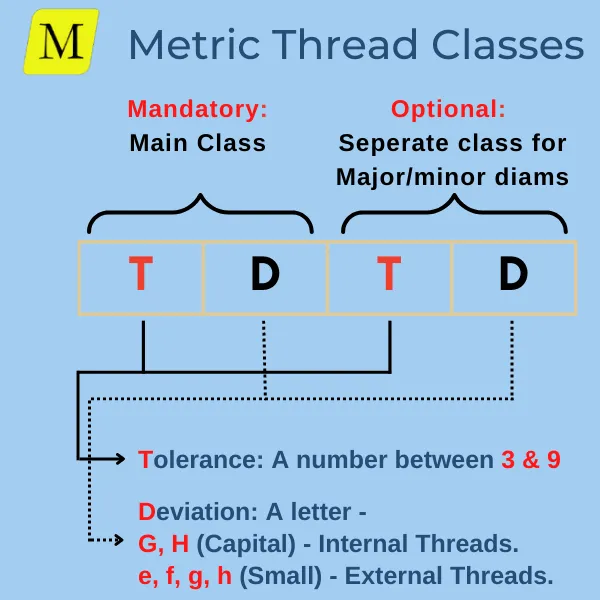

Metric Thread Classes

The class is written after the pitch. It is preceded by a “–” and consists of two or four characters. For example, for “M8 X 0.75 – 5g6g“, the class is 5g6g. The class defines the Deviation (allowance) and tolerance of the thread.

- Small letters represent external threads, while capital letters represent internal threads.

- Two charters long class mean that the class is valid for both the pitch and major/minor diameters.

- Four long charters mean a separate class for the pitch diameter (The first two characters) and major/minor diameters (The last two characters).

- If the class is omitted, the default class is used.

Metric Thread Class Syntax:

Threading Class Allowed Values:

External Threads:

- D: e, f, g, h

- T (Major Diameter): 4, 6, 8

- T (Pitch Diameter): 3, 4, 5, 6, 7, 8, 9

- Symbols: es, Td, Td2

Internal Threads:

- D: G, H

- T (Minor Diameter): 4, 5, 6, 7, 8

- T (Pitch Diameter): 4, 5, 6, 7, 8

- Symbols: EL, TD1, TD2

Metric Thread Classes Examples

| Class | Thread Type | Pitch Diameter | Major Diameter | Minor Diameter | |||

| T | D | T | D | T | D | ||

| Not Specified | External (Default) | 6 | g | 6 | g | ||

| Not Specified | Internal (Default) | 6 | H | 6 | H | ||

| 4e | External | 4 | e | 4 | e | ||

| 3g8f | External | 3 | g | 8 | f | ||

| 5G | Internal | 5 | G | 5 | G | ||

| 5G7H | Internal | 5 | G | 7 | H | ||

Class selection

The engineer can select any class for the male and female threads to achieve his design goals. However, ISO 965-1 recommends limiting the choice according to a chart of “Recommended Classes”.

The choice of the recommended class is made according to two parameters:

Tolerance Quality:

- F – Fine: for precision threads, when a minimal variation of fit is needed.

- M – Medium: for general use.

- C – Coarse: for cases where manufacturing difficulties can arise, for example, when threading hot-rolled bars and long blind holes.

Length of Engagement:

- N – Normal: Defined for each thread in the below table.

- S – Short: Shorter than the “Normal” length.

- L – Long: Longer than the “Normal length”.

- Select “N” When the length of engagement is unknown.

Normal length of engagement for metric threads

Type your thread description in the Search Box.

| id | Thread | Normal Length of Engagement (mm) | Normal Length of Engagement (Inch) |

|---|---|---|---|

| 1,000 | M1 | 0.6 -1.7 | 0.024 -0.067 |

| 2,000 | M1 X 0.2 | 0.5 -1.4 | 0.020 -0.055 |

| 1,001 | M1.1 | 0.6 -1.7 | 0.024 -0.067 |

| 2,001 | M1.1 X 0.2 | 0.5 -1.4 | 0.020 -0.055 |

| 1,002 | M1.2 | 0.6 -1.7 | 0.024 -0.067 |

| 2,002 | M1.2 X 0.2 | 0.5 -1.4 | 0.020 -0.055 |

| 1,003 | M1.4 | 0.7 -2.0 | 0.028 -0.079 |

| 2,003 | M1.4 X 0.2 | 0.5 -1.4 | 0.020 -0.055 |

| 1,004 | M1.6 | 0.8 -2.6 | 0.031 -0.102 |

| 2,004 | M1.6 X 0.2 | 0.5 -1.5 | 0.020 -0.059 |

| 1,005 | M1.8 | 0.8 -2.6 | 0.031 -0.102 |

| 2,005 | M1.8 X 0.2 | 0.5 -1.5 | 0.020 -0.059 |

| 1,019 | M10 | 5.0 -15.0 | 0.197 -0.591 |

| 2,022 | M10 X 0.75 | 2.4 -7.1 | 0.094 -0.280 |

| 2,021 | M10 X 1 | 3.0 -9.0 | 0.118 -0.354 |

| 2,020 | M10 X 1.25 | 4.0 -12.0 | 0.157 -0.472 |

| 3,037 | M100 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,038 | M100 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,039 | M100 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,040 | M100 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,041 | M105 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,042 | M105 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,043 | M105 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,044 | M105 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 1,020 | M11 | 5.0 -15.0 | 0.197 -0.591 |

| 2,024 | M11 X 0.75 | 2.4 -7.1 | 0.094 -0.280 |

| 2,023 | M11 X 1 | 3.0 -9.0 | 0.118 -0.354 |

| 3,045 | M110 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,046 | M110 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,047 | M110 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,048 | M110 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,049 | M115 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,050 | M115 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,051 | M115 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,052 | M115 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 1,021 | M12 | 6.0 -18.0 | 0.236 -0.709 |

| 2,027 | M12 X 1 | 3.8 -11.0 | 0.150 -0.433 |

| 2,026 | M12 X 1.25 | 4.5 -13.0 | 0.177 -0.512 |

| 2,025 | M12 X 1.5 | 5.6 -16.0 | 0.220 -0.630 |

| 3,053 | M120 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,054 | M120 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,055 | M120 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,056 | M120 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,057 | M125 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,058 | M125 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,059 | M125 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,060 | M125 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,061 | M125 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,062 | M130 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,063 | M130 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,064 | M130 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,065 | M130 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,066 | M130 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,067 | M135 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,068 | M135 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,069 | M135 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,070 | M135 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 1,022 | M14 | 8.0 -24.0 | 0.315 -0.945 |

| 2,030 | M14 X 1 | 3.8 -11.0 | 0.150 -0.433 |

| 2,029 | M14 X 1.25 | 4.5 -13.0 | 0.177 -0.512 |

| 2,028 | M14 X 1.5 | 5.6 -16.0 | 0.220 -0.630 |

| 3,071 | M140 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,072 | M140 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,073 | M140 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,074 | M140 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,075 | M140 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,076 | M145 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,077 | M145 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,078 | M145 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,079 | M145 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,080 | M150 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,081 | M150 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,082 | M150 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,083 | M150 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,084 | M150 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,085 | M155 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,086 | M155 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,087 | M155 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,088 | M155 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 1,024 | M16 | 8.0 -24.0 | 0.315 -0.945 |

| 2,032 | M16 X 1 | 3.8 -11.0 | 0.150 -0.433 |

| 2,031 | M16 X 1.5 | 5.6 -16.0 | 0.220 -0.630 |

| 3,089 | M160 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,090 | M160 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,091 | M160 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,092 | M160 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,093 | M165 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,094 | M165 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,095 | M165 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,096 | M170 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,097 | M170 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,098 | M170 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,099 | M170 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,100 | M175 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,101 | M175 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,102 | M175 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 1,026 | M18 | 10.0 -30.0 | 0.394 -1.181 |

| 2,035 | M18 X 1 | 3.8 -11.0 | 0.150 -0.433 |

| 2,034 | M18 X 1.5 | 5.6 -16.0 | 0.220 -0.630 |

| 2,033 | M18 X 2 | 8.0 -24.0 | 0.315 -0.945 |

| 3,103 | M180 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,104 | M180 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,105 | M180 X 6 | 36.0 -106.0 | 1.417 -4.173 |

| 3,106 | M180 X 8 | 45.0 -132.0 | 1.772 -5.197 |

| 3,107 | M185 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 3,108 | M185 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 3,109 | M185 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 3,110 | M190 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 3,111 | M190 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 3,112 | M190 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 3,113 | M190 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 3,114 | M195 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 3,115 | M195 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 3,116 | M195 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,006 | M2 | 1.0 -3.0 | 0.039 -0.118 |

| 2,006 | M2 X 0.25 | 0.6 -1.9 | 0.024 -0.075 |

| 1,007 | M2.2 | 1.3 -3.8 | 0.051 -0.150 |

| 2,007 | M2.2 X 0.25 | 0.6 -1.9 | 0.024 -0.075 |

| 1,008 | M2.5 | 1.3 -3.8 | 0.051 -0.150 |

| 2,008 | M2.5 X 0.35 | 0.8 -2.6 | 0.031 -0.102 |

| 1,027 | M20 | 10.0 -30.0 | 0.394 -1.181 |

| 2,038 | M20 X 1 | 3.8 -11.0 | 0.150 -0.433 |

| 2,037 | M20 X 1.5 | 5.6 -16.0 | 0.220 -0.630 |

| 2,036 | M20 X 2 | 8.0 -24.0 | 0.315 -0.945 |

| 3,117 | M200 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 3,118 | M200 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 3,119 | M200 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 3,120 | M200 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 3,121 | M205 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 3,122 | M205 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 3,123 | M205 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 2,095 | M210 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 2,094 | M210 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,093 | M210 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,087 | M210 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 1,028 | M22 | 10.0 -30.0 | 0.394 -1.181 |

| 2,041 | M22 X 1 | 3.8 -11.0 | 0.150 -0.433 |

| 2,040 | M22 X 1.5 | 5.6 -16.0 | 0.220 -0.630 |

| 2,039 | M22 X 2 | 8.0 -24.0 | 0.315 -0.945 |

| 2,098 | M220 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 2,097 | M220 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,096 | M220 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,089 | M220 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 2,101 | M230 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 2,100 | M230 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,099 | M230 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,091 | M230 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 2,044 | M24 X 1 | 4.0 -12.0 | 0.157 -0.472 |

| 2,043 | M24 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,104 | M240 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 2,103 | M240 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,102 | M240 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,093 | M240 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 2,107 | M250 X 3 | 20.0 -60.0 | 0.787 -2.362 |

| 2,106 | M250 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,105 | M250 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,095 | M250 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 2,109 | M260 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,108 | M260 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,097 | M260 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 1,032 | M27 | 12.0 -36.0 | 0.472 -1.417 |

| 2,047 | M27 X 1 | 4.0 -12.0 | 0.157 -0.472 |

| 2,046 | M27 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,045 | M27 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,111 | M270 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,110 | M270 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,099 | M270 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 2,113 | M280 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,112 | M280 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,101 | M280 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 2,115 | M290 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,114 | M290 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,103 | M290 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 1,009 | M3 | 1.5 -4.5 | 0.059 -0.177 |

| 2,009 | M3 X 0.35 | 1.0 -3.0 | 0.039 -0.118 |

| 1,010 | M3.5 | 1.7 -5.0 | 0.067 -0.197 |

| 2,010 | M3.5 X 0.35 | 1.0 -3.0 | 0.039 -0.118 |

| 1,034 | M30 | 15.0 -45.0 | 0.591 -1.772 |

| 2,051 | M30 X 1 | 4.0 -12.0 | 0.157 -0.472 |

| 2,050 | M30 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,049 | M30 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,048 | M30 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 2,117 | M300 X 4 | 26.0 -80.0 | 1.024 -3.150 |

| 2,116 | M300 X 6 | 40.0 -118.0 | 1.575 -4.646 |

| 1,105 | M300 X 8 | 50.0 -150.0 | 1.969 -5.906 |

| 1,036 | M33 | 15.0 -45.0 | 0.591 -1.772 |

| 2,054 | M33 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,053 | M33 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,052 | M33 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 1,038 | M36 | 18.0 -53.0 | 0.709 -2.087 |

| 2,057 | M36 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,056 | M36 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,055 | M36 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 1,040 | M39 | 18.0 -53.0 | 0.709 -2.087 |

| 2,060 | M39 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,059 | M39 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,058 | M39 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 1,011 | M4 | 2.0 -6.0 | 0.079 -0.236 |

| 2,011 | M4 X 0.5 | 1.5 -4.5 | 0.059 -0.177 |

| 1,012 | M4.5 | 2.2 -6.7 | 0.087 -0.264 |

| 2,012 | M4.5 X 0.5 | 1.5 -4.5 | 0.059 -0.177 |

| 1,042 | M42 | 21.0 -63.0 | 0.827 -2.480 |

| 2,064 | M42 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,063 | M42 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,062 | M42 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 2,061 | M42 X 4 | 18.0 -53.0 | 0.709 -2.087 |

| 1,043 | M45 | 21.0 -63.0 | 0.827 -2.480 |

| 2,068 | M45 X 1.5 | 6.3 -19.0 | 0.248 -0.748 |

| 2,067 | M45 X 2 | 8.5 -25.0 | 0.335 -0.984 |

| 2,066 | M45 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 2,065 | M45 X 4 | 18.0 -53.0 | 0.709 -2.087 |

| 1,044 | M48 | 24.0 -71.0 | 0.945 -2.795 |

| 2,072 | M48 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 2,071 | M48 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 2,070 | M48 X 3 | 12.0 -36.0 | 0.472 -1.417 |

| 2,070 | M48 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 2,069 | M48 X 4 | 18.0 -53.0 | 0.709 -2.087 |

| 2,069 | M48 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 1,013 | M5 | 2.5 -7.5 | 0.098 -0.295 |

| 2,013 | M5 X 0.5 | 1.5 -4.5 | 0.059 -0.177 |

| 1,046 | M52 | 24.0 -71.0 | 0.945 -2.795 |

| 2,076 | M52 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 2,075 | M52 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 2,074 | M52 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 2,073 | M52 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 1,048 | M56 | 28.0 -85.0 | 1.102 -3.346 |

| 2,080 | M56 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 2,079 | M56 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 2,078 | M56 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 2,077 | M56 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 1,015 | M6 | 3.0 -9.0 | 0.118 -0.354 |

| 2,014 | M6 X 0.75 | 2.4 -7.1 | 0.094 -0.280 |

| 1,050 | M60 | 28.0 -85.0 | 1.102 -3.346 |

| 2,084 | M60 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 2,083 | M60 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 2,082 | M60 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 2,081 | M60 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 1,052 | M64 | 32.0 -95.0 | 1.260 -3.740 |

| 2,088 | M64 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 2,087 | M64 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 2,086 | M64 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 2,085 | M64 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 1,054 | M68 | 32.0 -95.0 | 1.260 -3.740 |

| 2,092 | M68 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 2,091 | M68 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 2,090 | M68 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 2,089 | M68 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 1,016 | M7 | 3.0 -9.0 | 0.118 -0.354 |

| 2,015 | M7 X 0.75 | 2.4 -7.1 | 0.094 -0.280 |

| 3,000 | M70 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 3,001 | M70 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,002 | M70 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,003 | M70 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,004 | M70 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 3,005 | M72 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 3,006 | M72 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,007 | M72 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,008 | M72 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,009 | M72 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 3,010 | M75 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 3,011 | M75 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,012 | M75 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,013 | M75 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,014 | M75 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 3,015 | M76 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 3,016 | M76 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,017 | M76 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,018 | M76 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,019 | M76 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 1,017 | M8 | 4.0 -12.0 | 0.157 -0.472 |

| 2,017 | M8 X 0.75 | 2.4 -7.1 | 0.094 -0.280 |

| 2,016 | M8 X 1 | 3.0 -9.0 | 0.118 -0.354 |

| 3,020 | M80 X 1.5 | 7.5 -22.0 | 0.295 -0.866 |

| 3,021 | M80 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,022 | M80 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,023 | M80 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,024 | M80 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 3,025 | M85 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,026 | M85 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,027 | M85 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,028 | M85 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 1,018 | M9 | 4.0 -12.0 | 0.157 -0.472 |

| 2,019 | M9 X 0.75 | 2.4 -7.1 | 0.094 -0.280 |

| 2,018 | M9 X 1 | 3.0 -9.0 | 0.118 -0.354 |

| 3,029 | M90 X 2 | 9.5 -28.0 | 0.374 -1.102 |

| 3,030 | M90 X 3 | 15.0 -45.0 | 0.591 -1.772 |

| 3,031 | M90 X 4 | 19.0 -56.0 | 0.748 -2.205 |

| 3,032 | M90 X 6 | 32.0 -95.0 | 1.260 -3.740 |

| 3,033 | M95 X 2 | 12.0 -36.0 | 0.472 -1.417 |

| 3,034 | M95 X 3 | 18.0 -53.0 | 0.709 -2.087 |

| 3,035 | M95 X 4 | 24.0 -71.0 | 0.945 -2.795 |

| 3,036 | M95 X 6 | 36.0 -106.0 | 1.417 -4.173 |

Recommended class selection for metric threads

Blue Background– Default Classes

Green Background– First Choice Classes.

Yello Background – Second Choice Classes.

| Length of Engagment | ||||||||||

|

Tolerance Quality |

Thread Type |

S (Short) | M (Medium) | L (Long) | ||||||

| Fine Pitch | Internal | 4H | 5H | 6H | ||||||

| External | 3h4h | 4h | 4g | 5h4h | 5g4g | |||||

| Medium Pitch | Internal | 5H | 5G | 6H | 6G | 7H | 7G | |||

| External | 5h6h | 5g6g | 6g | 6f | 6e | 6h | 7h6h | 7g6g | 7e6e | |

| Coarse Pitch | Internal | 7H | 7G | 8H | 8G | |||||

| External | 8g | 8e | 9g8g | 9e8e | ||||||

Metric Thread Allowance (Deviations)

The allowance EL for internal threads and es for external threads is derived from the class. The approximate allowance can be calculated according to the below formulas:

- ELH = esh = 0

- ELG = esg ≈15 + 11 * P

- ese ≈50 + 11 * P

- esf ≈30 + 11 * P

- P is the pitch expressed in microns

- The result es/EL is in microns.

Unfortunately the above formulas are approximations only. The formal values must be obtained from ISO 965-1 or from the below chart

Allowance/Deviation of Metric Threads

- Type your thread description in the Search Box.

- Values are in Microns.

- For millimeters, divide by 1,000. For Inches, divide by 25,4000.

| id | Thread Diameter | Thread | e | f | g/G | h/H |

|---|---|---|---|---|---|---|

| 2,000 | 1.00 | M1 X 0.2 | -99 | -99 | 17 | 0 |

| 1,000 | 1.00 | M1 | -99 | -99 | 18 | 0 |

| 2,001 | 1.10 | M1.1 X 0.2 | -99 | -99 | 17 | 0 |

| 1,001 | 1.10 | M1.1 | -99 | -99 | 18 | 0 |

| 2,002 | 1.20 | M1.2 X 0.2 | -99 | -99 | 17 | 0 |

| 1,002 | 1.20 | M1.2 | -99 | -99 | 18 | 0 |

| 2,003 | 1.40 | M1.4 X 0.2 | -99 | -99 | 17 | 0 |

| 1,003 | 1.40 | M1.4 | -99 | -99 | 18 | 0 |

| 2,004 | 1.60 | M1.6 X 0.2 | -99 | -99 | 17 | 0 |

| 1,004 | 1.60 | M1.6 | -99 | 34 | 19 | 0 |

| 2,005 | 1.80 | M1.8 X 0.2 | -99 | -99 | 17 | 0 |

| 1,005 | 1.80 | M1.8 | -99 | 34 | 19 | 0 |

| 2,006 | 2.00 | M2 X 0.25 | -99 | -99 | 18 | 0 |

| 1,006 | 2.00 | M2 | -99 | 34 | 19 | 0 |

| 2,007 | 2.20 | M2.2 X 0.25 | -99 | -99 | 18 | 0 |

| 1,007 | 2.20 | M2.2 | -99 | 35 | 20 | 0 |

| 2,008 | 2.50 | M2.5 X 0.35 | -99 | 34 | 19 | 0 |

| 1,008 | 2.50 | M2.5 | -99 | 35 | 20 | 0 |

| 2,009 | 3.00 | M3 X 0.35 | -99 | 34 | 19 | 0 |

| 1,009 | 3.00 | M3 | 50 | 36 | 20 | 0 |

| 2,010 | 3.50 | M3.5 X 0.35 | -99 | 34 | 19 | 0 |

| 1,010 | 3.50 | M3.5 | 53 | 36 | 21 | 0 |

| 2,011 | 4.00 | M4 X 0.5 | 50 | 36 | 20 | 0 |

| 1,011 | 4.00 | M4 | 56 | 38 | 22 | 0 |

| 2,012 | 4.50 | M4.5 X 0.5 | 50 | 36 | 20 | 0 |

| 1,012 | 4.50 | M4.5 | 56 | 38 | 22 | 0 |

| 2,013 | 5.00 | M5 X 0.5 | 50 | 36 | 20 | 0 |

| 1,013 | 5.00 | M5 | 60 | 38 | 24 | 0 |

| 2,014 | 6.00 | M6 X 0.75 | 56 | 38 | 22 | 0 |

| 1,015 | 6.00 | M6 | 60 | 40 | 26 | 0 |

| 2,015 | 7.00 | M7 X 0.75 | 56 | 38 | 22 | 0 |

| 1,016 | 7.00 | M7 | 60 | 40 | 26 | 0 |

| 2,017 | 8.00 | M8 X 0.75 | 56 | 38 | 22 | 0 |

| 2,016 | 8.00 | M8 X 1 | 60 | 40 | 26 | 0 |

| 1,017 | 8.00 | M8 | 63 | 42 | 28 | 0 |

| 2,019 | 9.00 | M9 X 0.75 | 56 | 38 | 22 | 0 |

| 2,018 | 9.00 | M9 X 1 | 60 | 40 | 26 | 0 |

| 1,018 | 9.00 | M9 | 63 | 42 | 28 | 0 |

| 2,022 | 10.00 | M10 X 0.75 | 56 | 38 | 22 | 0 |

| 2,021 | 10.00 | M10 X 1 | 60 | 40 | 26 | 0 |

| 2,020 | 10.00 | M10 X 1.25 | 63 | 42 | 28 | 0 |

| 1,019 | 10.00 | M10 | 67 | 45 | 32 | 0 |

| 2,024 | 11.00 | M11 X 0.75 | 56 | 38 | 22 | 0 |

| 2,023 | 11.00 | M11 X 1 | 60 | 40 | 26 | 0 |

| 1,020 | 11.00 | M11 | 67 | 45 | 32 | 0 |

| 2,027 | 12.00 | M12 X 1 | 60 | 40 | 26 | 0 |

| 2,026 | 12.00 | M12 X 1.25 | 63 | 42 | 28 | 0 |

| 2,025 | 12.00 | M12 X 1.5 | 67 | 45 | 32 | 0 |

| 1,021 | 12.00 | M12 | 71 | 48 | 34 | 0 |

| 2,030 | 14.00 | M14 X 1 | 60 | 40 | 26 | 0 |

| 2,029 | 14.00 | M14 X 1.25 | 63 | 42 | 28 | 0 |

| 2,028 | 14.00 | M14 X 1.5 | 67 | 45 | 32 | 0 |

| 1,022 | 14.00 | M14 | 71 | 52 | 38 | 0 |

| 2,032 | 16.00 | M16 X 1 | 60 | 40 | 26 | 0 |

| 2,031 | 16.00 | M16 X 1.5 | 67 | 45 | 32 | 0 |

| 1,024 | 16.00 | M16 | 71 | 52 | 38 | 0 |

| 2,035 | 18.00 | M18 X 1 | 60 | 40 | 26 | 0 |

| 2,034 | 18.00 | M18 X 1.5 | 67 | 45 | 32 | 0 |

| 2,033 | 18.00 | M18 X 2 | 71 | 52 | 38 | 0 |

| 1,026 | 18.00 | M18 | 80 | 58 | 42 | 0 |

| 2,038 | 20.00 | M20 X 1 | 60 | 40 | 26 | 0 |

| 2,037 | 20.00 | M20 X 1.5 | 67 | 45 | 32 | 0 |

| 2,036 | 20.00 | M20 X 2 | 71 | 52 | 38 | 0 |

| 1,027 | 20.00 | M20 | 80 | 58 | 42 | 0 |

| 2,041 | 22.00 | M22 X 1 | 60 | 40 | 26 | 0 |

| 2,040 | 22.00 | M22 X 1.5 | 67 | 45 | 32 | 0 |

| 2,039 | 22.00 | M22 X 2 | 71 | 52 | 38 | 0 |

| 1,028 | 22.00 | M22 | 80 | 58 | 42 | 0 |

| 2,044 | 24.00 | M24 X 1 | 60 | 40 | 26 | 0 |

| 2,043 | 24.00 | M24 X 1.5 | 67 | 45 | 32 | 0 |

| 2,042 | 24.00 | M24 X 2 | 71 | 52 | 38 | 0 |

| 1,029 | 24.00 | M24 | 85 | 63 | 48 | 0 |

| 2,047 | 27.00 | M27 X 1 | 60 | 40 | 26 | 0 |

| 2,046 | 27.00 | M27 X 1.5 | 67 | 45 | 32 | 0 |

| 2,045 | 27.00 | M27 X 2 | 71 | 52 | 38 | 0 |

| 1,032 | 27.00 | M27 | 85 | 63 | 48 | 0 |

| 2,051 | 30.00 | M30 X 1 | 60 | 40 | 26 | 0 |

| 2,050 | 30.00 | M30 X 1.5 | 67 | 45 | 32 | 0 |

| 2,049 | 30.00 | M30 X 2 | 71 | 52 | 38 | 0 |

| 2,048 | 30.00 | M30 X 3 | 85 | 63 | 48 | 0 |

| 1,034 | 30.00 | M30 | 90 | 70 | 53 | 0 |

| 2,054 | 33.00 | M33 X 1.5 | 67 | 45 | 32 | 0 |

| 2,053 | 33.00 | M33 X 2 | 71 | 52 | 38 | 0 |

| 2,052 | 33.00 | M33 X 3 | 85 | 63 | 48 | 0 |

| 1,036 | 33.00 | M33 | 90 | 70 | 53 | 0 |

| 2,057 | 36.00 | M36 X 1.5 | 67 | 45 | 32 | 0 |

| 2,056 | 36.00 | M36 X 2 | 71 | 52 | 38 | 0 |

| 2,055 | 36.00 | M36 X 3 | 85 | 63 | 48 | 0 |

| 1,038 | 36.00 | M36 | 95 | 75 | 60 | 0 |

| 2,060 | 39.00 | M39 X 1.5 | 67 | 45 | 32 | 0 |

| 2,059 | 39.00 | M39 X 2 | 71 | 52 | 38 | 0 |

| 2,058 | 39.00 | M39 X 3 | 85 | 63 | 48 | 0 |

| 1,040 | 39.00 | M39 | 95 | 75 | 60 | 0 |

| 2,064 | 42.00 | M42 X 1.5 | 67 | 45 | 32 | 0 |

| 2,063 | 42.00 | M42 X 2 | 71 | 52 | 38 | 0 |

| 2,062 | 42.00 | M42 X 3 | 85 | 63 | 48 | 0 |

| 2,061 | 42.00 | M42 X 4 | 95 | 75 | 60 | 0 |

| 1,042 | 42.00 | M42 | 100 | 80 | 63 | 0 |

| 2,068 | 45.00 | M45 X 1.5 | 67 | 45 | 32 | 0 |

| 2,067 | 45.00 | M45 X 2 | 71 | 52 | 38 | 0 |

| 2,066 | 45.00 | M45 X 3 | 85 | 63 | 48 | 0 |

| 2,065 | 45.00 | M45 X 4 | 95 | 75 | 60 | 0 |

| 1,043 | 45.00 | M45 | 100 | 80 | 63 | 0 |

| 2,072 | 48.00 | M48 X 1.5 | 67 | 45 | 32 | 0 |

| 2,071 | 48.00 | M48 X 2 | 71 | 52 | 38 | 0 |

| 2,070 | 48.00 | M48 X 3 | 85 | 63 | 48 | 0 |

| 2,069 | 48.00 | M48 X 4 | 95 | 75 | 60 | 0 |

| 1,044 | 48.00 | M48 | 106 | 85 | 71 | 0 |

| 2,076 | 52.00 | M52 X 1.5 | 67 | 45 | 32 | 0 |

| 2,075 | 52.00 | M52 X 2 | 71 | 52 | 38 | 0 |

| 2,074 | 52.00 | M52 X 3 | 85 | 63 | 48 | 0 |

| 2,073 | 52.00 | M52 X 4 | 95 | 75 | 60 | 0 |

| 1,046 | 52.00 | M52 | 106 | 85 | 71 | 0 |

| 2,080 | 56.00 | M56 X 1.5 | 67 | 45 | 32 | 0 |

| 2,079 | 56.00 | M56 X 2 | 71 | 52 | 38 | 0 |

| 2,078 | 56.00 | M56 X 3 | 85 | 63 | 48 | 0 |

| 2,077 | 56.00 | M56 X 4 | 95 | 75 | 60 | 0 |

| 1,048 | 56.00 | M56 | 112 | 90 | 75 | 0 |

| 2,084 | 60.00 | M60 X 1.5 | 67 | 45 | 32 | 0 |

| 2,083 | 60.00 | M60 X 2 | 71 | 52 | 38 | 0 |

| 2,082 | 60.00 | M60 X 3 | 85 | 63 | 48 | 0 |

| 2,081 | 60.00 | M60 X 4 | 95 | 75 | 60 | 0 |

| 1,050 | 60.00 | M60 | 112 | 90 | 75 | 0 |

| 2,088 | 64.00 | M64 X 1.5 | 67 | 45 | 32 | 0 |

| 2,087 | 64.00 | M64 X 2 | 71 | 52 | 38 | 0 |

| 2,086 | 64.00 | M64 X 3 | 85 | 63 | 48 | 0 |

| 2,085 | 64.00 | M64 X 4 | 95 | 75 | 60 | 0 |

| 1,052 | 64.00 | M64 | 118 | 95 | 80 | 0 |

| 2,092 | 68.00 | M68 X 1.5 | 67 | 45 | 32 | 0 |

| 2,091 | 68.00 | M68 X 2 | 71 | 52 | 38 | 0 |

| 2,090 | 68.00 | M68 X 3 | 85 | 63 | 48 | 0 |

| 2,089 | 68.00 | M68 X 4 | 95 | 75 | 60 | 0 |

| 1,054 | 68.00 | M68 | 118 | 95 | 80 | 0 |

| 3,000 | 70.00 | M70 X 1.5 | 67 | 45 | 32 | 0 |

| 3,001 | 70.00 | M70 X 2 | 71 | 52 | 38 | 0 |

| 3,002 | 70.00 | M70 X 3 | 85 | 63 | 48 | 0 |

| 3,003 | 70.00 | M70 X 4 | 95 | 75 | 60 | 0 |

| 3,004 | 70.00 | M70 X 6 | 118 | 95 | 80 | 0 |

| 3,005 | 72.00 | M72 X 1.5 | 67 | 45 | 32 | 0 |

| 3,006 | 72.00 | M72 X 2 | 71 | 52 | 38 | 0 |

| 3,007 | 72.00 | M72 X 3 | 85 | 63 | 48 | 0 |

| 3,008 | 72.00 | M72 X 4 | 95 | 75 | 60 | 0 |

| 3,009 | 72.00 | M72 X 6 | 118 | 95 | 80 | 0 |

| 3,010 | 75.00 | M75 X 1.5 | 67 | 45 | 32 | 0 |

| 3,011 | 75.00 | M75 X 2 | 71 | 52 | 38 | 0 |

| 3,012 | 75.00 | M75 X 3 | 85 | 63 | 48 | 0 |

| 3,013 | 75.00 | M75 X 4 | 95 | 75 | 60 | 0 |

| 3,014 | 75.00 | M75 X 6 | 118 | 95 | 80 | 0 |

| 3,015 | 76.00 | M76 X 1.5 | 67 | 45 | 32 | 0 |

| 3,016 | 76.00 | M76 X 2 | 71 | 52 | 38 | 0 |

| 3,017 | 76.00 | M76 X 3 | 85 | 63 | 48 | 0 |

| 3,018 | 76.00 | M76 X 4 | 95 | 75 | 60 | 0 |

| 3,019 | 76.00 | M76 X 6 | 118 | 95 | 80 | 0 |

| 3,020 | 80.00 | M80 X 1.5 | 67 | 45 | 32 | 0 |

| 3,021 | 80.00 | M80 X 2 | 71 | 52 | 38 | 0 |

| 3,022 | 80.00 | M80 X 3 | 85 | 63 | 48 | 0 |

| 3,023 | 80.00 | M80 X 4 | 95 | 75 | 60 | 0 |

| 3,024 | 80.00 | M80 X 6 | 118 | 95 | 80 | 0 |

| 3,025 | 85.00 | M85 X 2 | 71 | 52 | 38 | 0 |

| 3,026 | 85.00 | M85 X 3 | 85 | 63 | 48 | 0 |

| 3,027 | 85.00 | M85 X 4 | 95 | 75 | 60 | 0 |

| 3,028 | 85.00 | M85 X 6 | 118 | 95 | 80 | 0 |

| 3,029 | 90.00 | M90 X 2 | 71 | 52 | 38 | 0 |

| 3,030 | 90.00 | M90 X 3 | 85 | 63 | 48 | 0 |

| 3,031 | 90.00 | M90 X 4 | 95 | 75 | 60 | 0 |

| 3,032 | 90.00 | M90 X 6 | 118 | 95 | 80 | 0 |

| 3,033 | 95.00 | M95 X 2 | 71 | 52 | 38 | 0 |

| 3,034 | 95.00 | M95 X 3 | 85 | 63 | 48 | 0 |

| 3,035 | 95.00 | M95 X 4 | 95 | 75 | 60 | 0 |

| 3,036 | 95.00 | M95 X 6 | 118 | 95 | 80 | 0 |

| 3,037 | 100.00 | M100 X 2 | 71 | 52 | 38 | 0 |

| 3,038 | 100.00 | M100 X 3 | 85 | 63 | 48 | 0 |

| 3,039 | 100.00 | M100 X 4 | 95 | 75 | 60 | 0 |

| 3,040 | 100.00 | M100 X 6 | 118 | 95 | 80 | 0 |

| 3,041 | 105.00 | M105 X 2 | 71 | 52 | 38 | 0 |

| 3,042 | 105.00 | M105 X 3 | 85 | 63 | 48 | 0 |

| 3,043 | 105.00 | M105 X 4 | 95 | 75 | 60 | 0 |

| 3,044 | 105.00 | M105 X 6 | 118 | 95 | 80 | 0 |

| 3,045 | 110.00 | M110 X 2 | 71 | 52 | 38 | 0 |

| 3,046 | 110.00 | M110 X 3 | 85 | 63 | 48 | 0 |

| 3,047 | 110.00 | M110 X 4 | 95 | 75 | 60 | 0 |

| 3,048 | 110.00 | M110 X 6 | 118 | 95 | 80 | 0 |

| 3,049 | 115.00 | M115 X 2 | 71 | 52 | 38 | 0 |

| 3,050 | 115.00 | M115 X 3 | 85 | 63 | 48 | 0 |

| 3,051 | 115.00 | M115 X 4 | 95 | 75 | 60 | 0 |

| 3,052 | 115.00 | M115 X 6 | 118 | 95 | 80 | 0 |

| 3,053 | 120.00 | M120 X 2 | 71 | 52 | 38 | 0 |

| 3,054 | 120.00 | M120 X 3 | 85 | 63 | 48 | 0 |

| 3,055 | 120.00 | M120 X 4 | 95 | 75 | 60 | 0 |

| 3,056 | 120.00 | M120 X 6 | 118 | 95 | 80 | 0 |

| 3,057 | 125.00 | M125 X 2 | 71 | 52 | 38 | 0 |

| 3,058 | 125.00 | M125 X 3 | 85 | 63 | 48 | 0 |

| 3,059 | 125.00 | M125 X 4 | 95 | 75 | 60 | 0 |

| 3,060 | 125.00 | M125 X 6 | 118 | 95 | 80 | 0 |

| 3,061 | 125.00 | M125 X 8 | 140 | 118 | 100 | 0 |

| 3,062 | 130.00 | M130 X 2 | 71 | 52 | 38 | 0 |

| 3,063 | 130.00 | M130 X 3 | 85 | 63 | 48 | 0 |

| 3,064 | 130.00 | M130 X 4 | 95 | 75 | 60 | 0 |

| 3,065 | 130.00 | M130 X 6 | 118 | 95 | 80 | 0 |

| 3,066 | 130.00 | M130 X 8 | 140 | 118 | 100 | 0 |

| 3,067 | 135.00 | M135 X 2 | 71 | 52 | 38 | 0 |

| 3,068 | 135.00 | M135 X 3 | 85 | 63 | 48 | 0 |

| 3,069 | 135.00 | M135 X 4 | 95 | 75 | 60 | 0 |

| 3,070 | 135.00 | M135 X 6 | 118 | 95 | 80 | 0 |

| 3,071 | 140.00 | M140 X 2 | 71 | 52 | 38 | 0 |

| 3,072 | 140.00 | M140 X 3 | 85 | 63 | 48 | 0 |

| 3,073 | 140.00 | M140 X 4 | 95 | 75 | 60 | 0 |

| 3,074 | 140.00 | M140 X 6 | 118 | 95 | 80 | 0 |

| 3,075 | 140.00 | M140 X 8 | 140 | 118 | 100 | 0 |

| 3,076 | 145.00 | M145 X 2 | 71 | 52 | 38 | 0 |

| 3,077 | 145.00 | M145 X 3 | 85 | 63 | 48 | 0 |

| 3,078 | 145.00 | M145 X 4 | 95 | 75 | 60 | 0 |

| 3,079 | 145.00 | M145 X 6 | 118 | 95 | 80 | 0 |

| 3,080 | 150.00 | M150 X 2 | 71 | 52 | 38 | 0 |

| 3,081 | 150.00 | M150 X 3 | 85 | 63 | 48 | 0 |

| 3,082 | 150.00 | M150 X 4 | 95 | 75 | 60 | 0 |

| 3,083 | 150.00 | M150 X 6 | 118 | 95 | 80 | 0 |

| 3,084 | 150.00 | M150 X 8 | 140 | 118 | 100 | 0 |

| 3,085 | 155.00 | M155 X 2 | 71 | 52 | 38 | 0 |

| 3,086 | 155.00 | M155 X 3 | 85 | 63 | 48 | 0 |

| 3,087 | 155.00 | M155 X 4 | 95 | 75 | 60 | 0 |

| 3,088 | 155.00 | M155 X 6 | 118 | 95 | 80 | 0 |

| 3,089 | 160.00 | M160 X 3 | 85 | 63 | 48 | 0 |

| 3,090 | 160.00 | M160 X 4 | 95 | 75 | 60 | 0 |

| 3,091 | 160.00 | M160 X 6 | 118 | 95 | 80 | 0 |

| 3,092 | 160.00 | M160 X 8 | 140 | 118 | 100 | 0 |

| 3,093 | 165.00 | M165 X 3 | 85 | 63 | 48 | 0 |

| 3,094 | 165.00 | M165 X 4 | 95 | 75 | 60 | 0 |

| 3,095 | 165.00 | M165 X 6 | 118 | 95 | 80 | 0 |

| 3,096 | 170.00 | M170 X 3 | 85 | 63 | 48 | 0 |

| 3,097 | 170.00 | M170 X 4 | 95 | 75 | 60 | 0 |

| 3,098 | 170.00 | M170 X 6 | 118 | 95 | 80 | 0 |

| 3,099 | 170.00 | M170 X 8 | 140 | 118 | 100 | 0 |

| 3,100 | 175.00 | M175 X 3 | 85 | 63 | 48 | 0 |

| 3,101 | 175.00 | M175 X 4 | 95 | 75 | 60 | 0 |

| 3,102 | 175.00 | M175 X 6 | 118 | 95 | 80 | 0 |

| 3,103 | 180.00 | M180 X 3 | 85 | 63 | 48 | 0 |

| 3,104 | 180.00 | M180 X 4 | 95 | 75 | 60 | 0 |

| 3,105 | 180.00 | M180 X 6 | 118 | 95 | 80 | 0 |

| 3,106 | 180.00 | M180 X 8 | 140 | 118 | 100 | 0 |

| 3,107 | 185.00 | M185 X 3 | 85 | 63 | 48 | 0 |

| 3,108 | 185.00 | M185 X 4 | 95 | 75 | 60 | 0 |

| 3,109 | 185.00 | M185 X 6 | 118 | 95 | 80 | 0 |

| 3,110 | 190.00 | M190 X 3 | 85 | 63 | 48 | 0 |

| 3,111 | 190.00 | M190 X 4 | 95 | 75 | 60 | 0 |

| 3,112 | 190.00 | M190 X 6 | 118 | 95 | 80 | 0 |

| 3,113 | 190.00 | M190 X 8 | 140 | 118 | 100 | 0 |

| 3,114 | 195.00 | M195 X 3 | 85 | 63 | 48 | 0 |

| 3,115 | 195.00 | M195 X 4 | 95 | 75 | 60 | 0 |

| 3,116 | 195.00 | M195 X 6 | 118 | 95 | 80 | 0 |

| 3,117 | 200.00 | M200 X 3 | 85 | 63 | 48 | 0 |

| 3,118 | 200.00 | M200 X 4 | 95 | 75 | 60 | 0 |

| 3,119 | 200.00 | M200 X 6 | 118 | 95 | 80 | 0 |

| 3,120 | 200.00 | M200 X 8 | 140 | 118 | 100 | 0 |

| 3,121 | 205.00 | M205 X 3 | 85 | 63 | 48 | 0 |

| 3,122 | 205.00 | M205 X 4 | 95 | 75 | 60 | 0 |

| 3,123 | 205.00 | M205 X 6 | 118 | 95 | 80 | 0 |

| 2,095 | 210.00 | M210 X 3 | 85 | 63 | 48 | 0 |

| 2,094 | 210.00 | M210 X 4 | 95 | 75 | 60 | 0 |

| 2,093 | 210.00 | M210 X 6 | 118 | 95 | 80 | 0 |

| 1,087 | 210.00 | M210 X 8 | 140 | 118 | 100 | 0 |

| 2,098 | 220.00 | M220 X 3 | 85 | 63 | 48 | 0 |

| 2,097 | 220.00 | M220 X 4 | 95 | 75 | 60 | 0 |

| 2,096 | 220.00 | M220 X 6 | 118 | 95 | 80 | 0 |

| 1,089 | 220.00 | M220 X 8 | 140 | 118 | 100 | 0 |

| 2,101 | 230.00 | M230 X 3 | 85 | 63 | 48 | 0 |

| 2,100 | 230.00 | M230 X 4 | 95 | 75 | 60 | 0 |

| 2,099 | 230.00 | M230 X 6 | 118 | 95 | 80 | 0 |

| 1,091 | 230.00 | M230 X 8 | 140 | 118 | 100 | 0 |

| 2,104 | 240.00 | M240 X 3 | 85 | 63 | 48 | 0 |

| 2,103 | 240.00 | M240 X 4 | 95 | 75 | 60 | 0 |

| 2,102 | 240.00 | M240 X 6 | 118 | 95 | 80 | 0 |

| 1,093 | 240.00 | M240 X 8 | 140 | 118 | 100 | 0 |

| 2,107 | 250.00 | M250 X 3 | 85 | 63 | 48 | 0 |

| 2,106 | 250.00 | M250 X 4 | 95 | 75 | 60 | 0 |

| 2,105 | 250.00 | M250 X 6 | 118 | 95 | 80 | 0 |

| 1,095 | 250.00 | M250 X 8 | 140 | 118 | 100 | 0 |

| 2,109 | 260.00 | M260 X 4 | 95 | 75 | 60 | 0 |

| 2,108 | 260.00 | M260 X 6 | 118 | 95 | 80 | 0 |

| 1,097 | 260.00 | M260 X 8 | 140 | 118 | 100 | 0 |

| 2,111 | 270.00 | M270 X 4 | 95 | 75 | 60 | 0 |

| 2,110 | 270.00 | M270 X 6 | 118 | 95 | 80 | 0 |

| 1,099 | 270.00 | M270 X 8 | 140 | 118 | 100 | 0 |

| 2,113 | 280.00 | M280 X 4 | 95 | 75 | 60 | 0 |

| 2,112 | 280.00 | M280 X 6 | 118 | 95 | 80 | 0 |

| 1,101 | 280.00 | M280 X 8 | 140 | 118 | 100 | 0 |

| 2,115 | 290.00 | M290 X 4 | 95 | 75 | 60 | 0 |

| 2,114 | 290.00 | M290 X 6 | 118 | 95 | 80 | 0 |

| 1,103 | 290.00 | M290 X 8 | 140 | 118 | 100 | 0 |

| 2,117 | 300.00 | M300 X 4 | 95 | 75 | 60 | 0 |

| 2,116 | 300.00 | M300 X 6 | 118 | 95 | 80 | 0 |

| 1,105 | 300.00 | M300 X 8 | 140 | 118 | 100 | 0 |

Metric Thread Tolerances

The tolerances TD for internal threads and Td for external threads is derived from the class. The approximate tolerances can be calculated according to the below formulas.

- Td – Tolerance for External Major Diameter

- Td2 – Tolerance for External Pitch Diameter

- TD1 – Tolerance for Internal Minor Diameter

- TD2 – Tolerance for Internal Pitch Diameter

- P & D – Given in mm

- T – Tolerances results are in microns. (for mm divide by 1,000 and for inches by 254,000).

- T(i) – Tolerance for external diameter grade i. For example, Td(6) is the tolerance for class g6, and Td(8) is for class g8.

Formulas for tolerances of Metric Threads

External

\( \large T_d(4) \approx {0.63}\times{T_d(6)}\)

\( \large T_d(8) \approx {1.6}\times{T_d(6)} \)

\( \large T_{d2}(6) \approx 90 \times P^{0.4} \times d^{0.1} \)

\( \large T_{d2}(3) \approx {0.5}\times{T_{d2}(6)}\)

\( \large T_{d2}(4) \approx {0.63}\times{T_{d2}(6)} \)

\( \large T_{d2}(5) \approx {0.8}\times{T_{d2}(6)} \)

\( \large T_{d2}(7) \approx {1.25}\times{T_{d2}(6)} \)

\( \large T_{d2}(8) \approx {1.6}\times{T_{d2}(6)} \)

\( \large T_{d2}(9) \approx {2.0}\times{T_{d2}(6)} \)

Internal

\( \text{For P>=1 mm} \)

\( \large T_{D1}(6) \approx 230 \times P^{0.7}\)

\( \large T_{D1}(4) \approx {0.63}\times{T_d(6)}\)

\( \large T_{D1}(5) \approx {0.8}\times{T_d(6)}\)

\( \large T_{D1}(7) \approx {1.25}\times{T_d(6)}\)

\( \large T_{D1}(8) \approx {1.6}\times{T_d(6)} \)

\( \large T_{D2}(4) \approx {0.85}\times{T_{d2}(6)}\)

\( \large T_{D2}(5) \approx {1.06}\times{T_{d2}(6)}\)

\( \large T_{D2}(6) \approx {1.32}\times{T_{d2}(6)}\)

\( \large T_{D2}(7) \approx {1.7}\times{T_{d2}(6)}\)

\( \large T_{D2}(8) \approx {2.12}\times{T_{d2}(6)} \)

The above formulas are approximations. For the formal values, use the below chart or standard ISO 965-1

Metric Thread Tolerances Chart

- Type your thread description in the Search Box.

- Values are in Microns.

- For millimeters, divide by 1,000. For Inches, divide by 25,4000.

- The numbers (3 -9) in the top row represent the class grade (e.g., h6, g8, etc.)

| id | Thread | Symbol | Diameter Type | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|---|

| 2,000 | M1 X 0.2 | Td | External Major Diameter | -99 | 36 | -99 | 56 | -99 | -99 | -99 |

| 2,000 | M1 X 0.2 | Td2 | External Pitch Diameter | 24 | 30 | 38 | 48 | -99 | -99 | -99 |

| 2,000 | M1 X 0.2 | TD1 | Internal Minor Diameter | -99 | 38 | -99 | -99 | -99 | -99 | -99 |

| 2,000 | M1 X 0.2 | TD2 | Internal Pitch Diameter | -99 | 40 | -99 | -99 | -99 | -99 | -99 |

| 1,000 | M1 | Td | External Major Diameter | -99 | 42 | -99 | 67 | -99 | -99 | -99 |

| 1,000 | M1 | Td2 | External Pitch Diameter | 26 | 34 | 42 | 53 | -99 | -99 | -99 |

| 1,000 | M1 | TD1 | Internal Minor Diameter | -99 | 45 | 56 | -99 | -99 | -99 | -99 |

| 1,000 | M1 | TD2 | Internal Pitch Diameter | -99 | 45 | 56 | -99 | -99 | -99 | -99 |

| 2,001 | M1.1 X 0.2 | Td | External Major Diameter | -99 | 36 | -99 | 56 | -99 | -99 | -99 |

| 2,001 | M1.1 X 0.2 | Td2 | External Pitch Diameter | 24 | 30 | 38 | 48 | -99 | -99 | -99 |

| 2,001 | M1.1 X 0.2 | TD1 | Internal Minor Diameter | -99 | 38 | -99 | -99 | -99 | -99 | -99 |

| 2,001 | M1.1 X 0.2 | TD2 | Internal Pitch Diameter | -99 | 40 | -99 | -99 | -99 | -99 | -99 |

| 1,001 | M1.1 | Td | External Major Diameter | -99 | 42 | -99 | 67 | -99 | -99 | -99 |

| 1,001 | M1.1 | Td2 | External Pitch Diameter | 26 | 34 | 42 | 53 | -99 | -99 | -99 |

| 1,001 | M1.1 | TD1 | Internal Minor Diameter | -99 | 45 | 56 | -99 | -99 | -99 | -99 |

| 1,001 | M1.1 | TD2 | Internal Pitch Diameter | -99 | 45 | 56 | -99 | -99 | -99 | -99 |