Table of Contents

The term Chip load (also called Maximum Chip Thickness), can be confusing since it has two different meanings that are commonly used.

Chip Load Calculator

Get recommended chip load per milling cutter diameter and workpiece material.

What is Chip Load?

Meaning #1 – How Chip load is used in milling catalogs, and by most machinists.

The maximum load that the cutting edge of a specific milling cutter (or indexable insert) can withstand without yielding or having a very short tool-life.

The chip load is specified in mm/tooth or Inch per tooth (IPT) units. This property is so helpful because it depends only on the geometry of the cutting edge and the type of workpiece material. It is independent of application conditions such as speed or depth of cut. It is convenient for both the tool suppliers and the users.

- For the cutting tool suppliers, it enables them to list the recommended feedrates in one chart, independent of the application conditions.

- The CNC programmers can input the chip load value from the cutting tool supplier into the Cad/Cam software, and the software calculates the correct table feed accordingly.

- Once the end-user figures out a chip load that works well for a cutter and material combination, they can use this number confidently in many other applications by calculating the table feed based on the known chip load each time.

Learn how to Calculate the Table Feed based on the cutter’s Chip Load recommendations

Meaning #2 – The physical meaning of Chip Load

The maximum width of the chip that the tooth (or indexable inserts) of a milling cutter cuts out of the material in one spindle rotation.

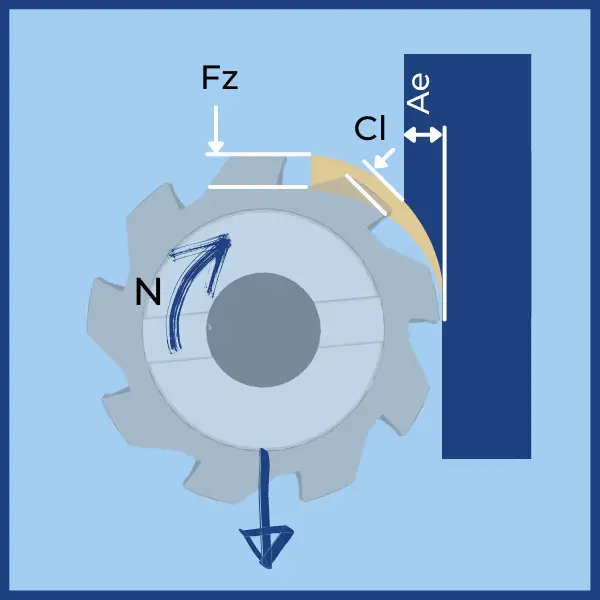

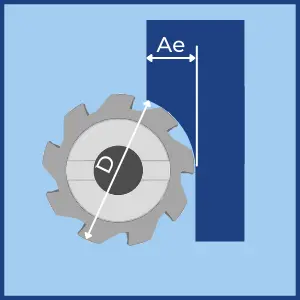

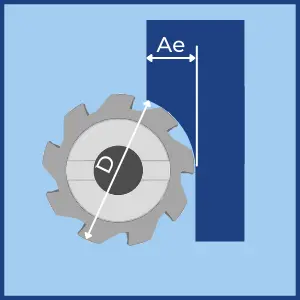

- The chip load equals exactly the feed per tooth (Fz) when the radial depth of cut (Ae) is greater or equal to the cutter radius. As Ae becomes smaller, the chip load also becomes smaller. Some people refer to the Fz as if it is the chip load. This is a mistake since it is not true in all conditions!

- The width of the chip is largest at the point of entry and gradually gets smaller until it is zero at the point of exit. The chip load is the maximum value. A related term is Average Chip thickness which is used for force and power calculations.

Chip Load Chart – Inch

Chip Load in IPT per Milling Cutter Diameter and workpiece material

Chip Load Chart – Metric

Chip Load in mm/tooth per Milling Cutter Diameter and workpiece material

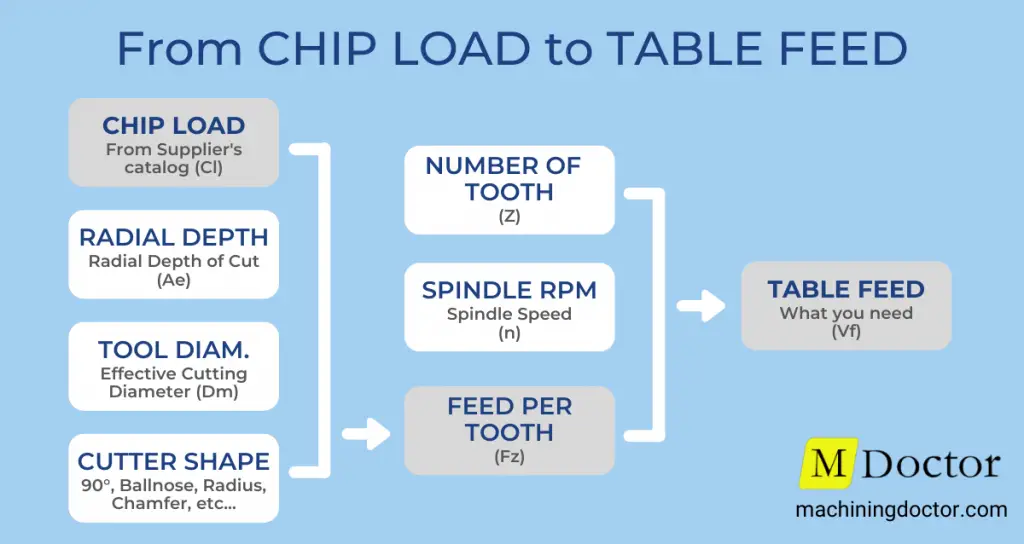

Getting Cutting Data from Chip Load

The chip load value by itself cannot be used to program the milling machine. The parameter used by the controllers is the Table Feed. However, the Chip Load is the basic parameter needed to calculate the Table Feed.

To calculate the Milling Feedrate, you will need first to prepare the following basic data:

- Chip Load [CL] – What you obtained from this calculator.

- Cutter Shape [90°, Ballnose, Chamfering, Round, etc]

- Cutter Diameter [D] – If you are using a shaped cutter (Non 90°), you should use the Effective Cutter Diameter.

- Number of Teeth [Z]

The user always knows the above three.

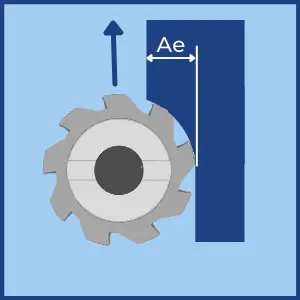

Radial Depth of Cut [Ae] – Depends on how you plan to perform your application.

Radial Depth of Cut [Ae] – Depends on how you plan to perform your application.- Cutting Speed [Vc] – Get wit with our Speeds and Feeds Calculator or from the tool supplier’s catalog/website.

With the above parameters, you can proceed to calculate the Milling Feed (Table Feed)

- Calculate the Chip Thinning factors in order to get the Feed per Tooth.

The Chip Thinning factors ensure that the actual Feed per Tooth [Fz} will maintain the desired Chip Load according to the tool geometry and application settings. - Radial Chip Thinning Factor [RCTF] –

The radial chip thinning factor should be implemented with the Radial Depth of Cut [Ae] being smaller than the cutter’s radius. (When Ae is bigger, the factor is 1). At very small Ae, the factor can be up to 3 times!

* Learn how maintaining a constant chip load can save you money!

Radial Chip Thinning factor calculation:

\( \huge \frac{1}{\sqrt{1-\left ( 1 – 2 \times \frac{Ae}{D} \right )^{2}}} \)

- Approach Angle Chip Thinning Factor [ACTF] –

The Approach Angle Chip Thinning factor should be implemented when the cutter is not a standard 90° shape (For example, a Ballnose or Chamfering cutter).

Chip Thinning factor for Chamfer/feed milling cutters:

\( \huge \frac{1}{\sin({K_{apr})}} \)

For other shaped (like Ballnose, Round inserts, etc.), visit our Chip Thinning Calculator

- Calculate the Feed per Tooth, based on the Chip load and Chip thinning factors:

- Calculate the RPM from the Cutting Speed and Cutter Diameter:

* If your Vc is in m/min units use 1000 instaed of 12 in the above formula.

- Final Stage: Calculate the Table Feed:

Check out our Speed and Feed Calculator that automatically takes all the above into account!