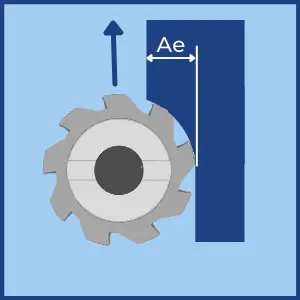

- The Radial depth of cut is also called Stepover and Cut Width.

- It is designated by ae or RDOC.

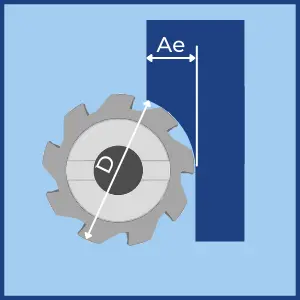

- The maximum possible radial depth is the cutter’s diameter.

- When the radial depth is larger or equal to the cutter’s radius, the chip load is similar to the feed per tooth.

- The chip load is reduced for smaller cut widths because of the chip thinning effect. (See below)

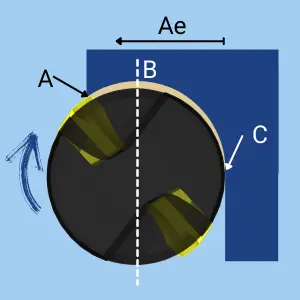

Chip Thinning Effect

- In a milling operation, the Chip Thickness varies between the point of entry (A) and the Point of Exit (C).

- When the Radial Depth of Cut is greater or equal to the cutter’s radius, The maximum Chip thickness equals the Feed Per Tooth.

- When the radial depth of cut is smaller than the cutter’s radius (Point B), the maximum chip thickness gradually decreases even though the feed per tooth remains the same.

- This phenomenon is called Chip Thinning.

Chip Thinning allows dramatic productivity gain since you can multiply the Feed by the Chip Thinning Factor (RCTF) while keeping the Chip Load within the recommended range! Learn more about it in our detailed guide about chip thinning

\( \large RCTF = \)

\( \huge \frac{1}{\sqrt{1-\left ( 1 – 2 \times \frac{Ae}{D} \right )^{2}}} \)

\( \huge \frac{1}{\sqrt{1-\left ( 1 – 2 \times \frac{Ae}{D} \right )^{2}}} \)