Cutting Speed Definition

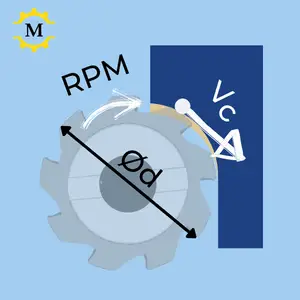

In machining, the words “Speed”, “Cutting Speed”, “SFM” and “Surface Speed” all refer to the relative linear velocity between the tip of the cutting edge and the workpiece. The definition is the same for all machining operations turning, milling, etc.

The way we utilize the above definition depends on the application. A solid understanding of the below use cases is fundamental to correct decision-making in machining.

Table of Content

Cutting Speed (SFM) Definition per Machining Application:

Cutting Speed (SFM) in Turning

In a turning operation, the workpiece is rotated by the spindle (and the cutting tool is stationary). The rotational speed of the spindle (measured in RPM) transforms into cutting speed at the diameter in which the turning insert touches the rotating raw material. Different diameters on the workpiece require different RPMs to get the same cutting speed.

Because of that, the CNC controller must constantly change the RPM to maintain a constant cutting speed. This is usually achieved by using the G96 CNC code.

Cutting Speed (SFM) in Milling

In a milling operation, the workpiece is stationary, and the spindle rotates the milling cutter. The rotational speed of the spindle (measured in RPM) transforms into cutting speed at the diameter in which the milling cutter touches the workpiece. Therefore, the RPM can stay constant during the whole operation. (Opposed to turning, as you can read above).

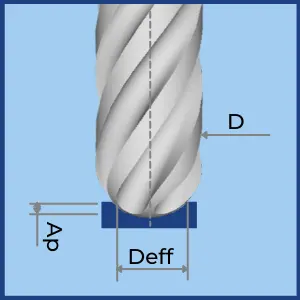

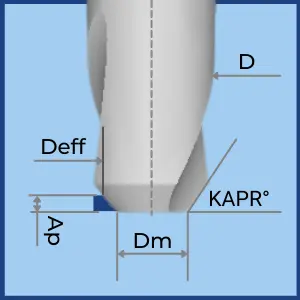

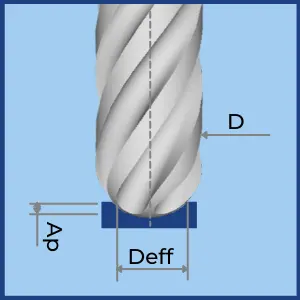

The above simplified description applies only to typical 90° cutters. In chamfered or ballnose milling cutters, the engagement point between the milling tool and the material also depends on the radial and axial depth of the cuts. The diameter at this point is called the “effective diameter” (Deff), and it should be used in the formulas to calculate the cutting speed (SFM).

Detailed formulas for effective diameter

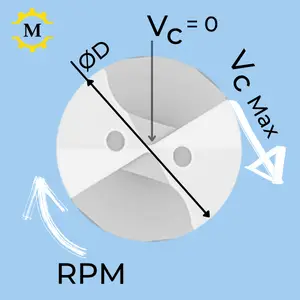

Cutting Speed (SFM) in Drilling

In a drilling operation (and milling plunging), the whole face of the cutting tool engages with the workpiece simultaneously. Since the cutting speed depends on the diameter of engagement (See formulas), each location on the drill “feels” a different cutting speed, and the cutting speed at the center-point is always zero. Because of that, drills are manufactured from “all-around” carbide grades that can also operate at very low cutting speeds. As a result, cutting speeds for drills should always be kept on the low side. (relative to milling and turning)

Cutting Speed (SFM) in Face Turing & Parting Off

In facing and parting off operations, the cutting tool travels from the outer diameter towards the center line and, in many cases, all the way to the center, where the diameter is zero.

The spindle speed (RPM) increases as the tool gets closer to the center to maintain the desired cutting speed. Since every machine has a maximum spindle speed limitation, the spindle speed will reach the limit at some point in the operation.

Because of that, some machinists prefer to work in G97 mode (Constant RPM) in these operations. As with drilling, you should opt for an all-around carbide grade that works well in both high and low cutting speeds.

This point is called the “Clamped Diameter” since the spindle speed is “clamped” to the maximum allowed RPM.

From the clamped diameter, the spindle speed remains constant, and the cutting speed decreases, reaching zero when the cutting tool is at the center line.

(D in inches and Vc in SFM)

(D in mm and Vc in m/min)

Cutting Speed Units

SFM – Surface Feet per Minue

SFM stands for “Surface feet per min”. It is the common unit to measure cutting speed in the US (But almost never used outside of the US). The speed is measured in feet/min instead of meters/min, which is the common unit that is used in most countries.

m/min – Meters per Minute

In countries that use the metric system, the common unit of measurement for cutting speed is Meters per Minute.

SFM / Meters per Minute conversion formulas

The conversion coefficients between SFM and meters per minute can be calculated by the below formulas:

Hence, the final formulas to convert from SFM to meters per minute (and vice versa) are as follows:

\( \large V_c[SFM] = V_c[mm/min] \times 3.3 \)

\( \small V_c[SFM] = V_c[mm/min] \times 3.3 \)

cutting speed Formulas

Since cutting speed is the linear velocity between the cutting tool and the material being cut, it is the product of the spindle speed times the radius of rotation. In non-rotating operations such as turning and grooving, it is the machined radius (Not the workpiece radius!). In rotating operations such as milling, it is the radius of the cutting tool at the point of engagement with the workpiece.

To unify the formulas, we will use the term “Effective Diameter” (deff) and show how to determine it for each typical machining operation.

Parameters:

- deff – Effective diamter. The diameter of rotation at the point of engagement. [Inches or milimetrs]

- n – Spindle Speed [RPM]

- Vc – Cutting Speed [SFM or Meters per minute]

SFM Formula (Inch Units)

Cutting Speed Formula (Metric Units)

Determining the Effective Diameter (deff) for each use case

To receive accurate results from these formulas, it is important to implement them with the correct effective diameter.

Deff for Cutting Speed

| Application | Formula |

|---|---|

|

Turing

|

\( \large d_{eff} = d \)

* Use the Machined diameter and not the workpiece diameter! |

|

90° Milling  |

\( \large d_{eff} = d \)

* The effective diameter is always the cutters diameter |

|

Milling (BallNose)

|

\( \large d_{eff}\, =\,2\times\sqrt{d\times\left (d - a_p\right)}\) |

|

Milling (Chamfer)

|

\( \large d_{eff} = d_{min}+\frac{2 \times a_p}{ \tan { \left( \text {KAPR} \right ) } } \) |

What is the correct cutting speed for your machining application?

The correct cutting speed is determined by the combination of:

- The Machinability of the workpiece material. (How much is the material resisting being cut)

- The carbide grade of the Cutting Tool. (How Wear Resistant is the cutting tool’s material and coating)

- The overall stability of the application.

There is a huge variety of workpiece materials and cutting tools grades. Determining the best cutting speed that will bring a good balance between productivity and tool-life is one of the most important skills for a Machinist or a tools engineer to master.

The Machining Doctor provides you with powerful tools to quickly obtain the correct cutting speed!

* Advanced Speed and Feed Calculator

* Cutting Speed recommendations for more than 700 raw materials

* Machinability chart with more than 200 materials