Carbide Grades is a general term in metallurgy referring to sintered WC material used for various applications such as Nozzles, Dies, Rollers, Crush Rolls, and Cutting Tools. It is classified by ISO code ranging from K01 to K40. However, in the machining jargon, the term “Carbide Grade”, or simply “Grade” refers to the combination of sintered tungsten carbide, coating, and other treatments of a cutting tool. Two cutting tools that are made of the exact same carbide material but have a different coating or post-treatment are designated by a different grade. This post is about the practical aspect of carbide grades for cutting tools.

Table of Contents

What is the Substrate of a Carbide Grade

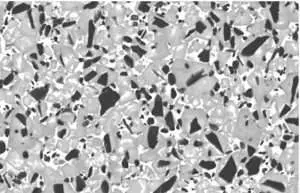

The substrate is the material of the bare cutting insert before coating and post-treatment. It is composed of 80-95% of WC. WC (also referred to as Wolfram) is a combination of tungsten (W) and carbon (C) refactored together. To give the substrate the desired properties, the manufacturers add various alloying elements. The main alloying element is 5-15% of cobalt (Co), which increases the substrate’s toughness (More cobalt=more toughness, Less cobalt=more hardness). The primary property of interest to the machinist is the hardness of the substrate. Very hard substrates have a hardness of 1800 HV and provide excellent wear resistance but are very brittle and can work only in very stable conditions. Very tough substrates have a hardness of about 1300 HV. They can operate only at lower cutting speeds, will wear out faster, but have much better resistance to interrupted cuts and unfavorable conditions. The right balance between hardness and toughness is critical for achieving a longer tool-life and higher productivity in each application.

Substrate Hardness Selection Guide

| Material | Continues | Semi | Interuppted |

|---|---|---|---|

| P | Hard | Medium | Tough |

| M | Hard | Medium | Tough |

| K | Hard | Medium-Hard | Medium |

| N | Hard | Medium-Hard | Medium |

| S | Hard | Medium-Hard | Tough |

Coating of Carbide Grades

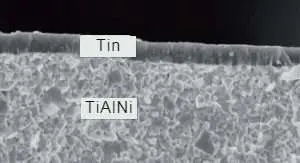

Most carbide inserts and solid carbide tools are coated with a thin layer of 3 to 20 microns (0.0001-0.0007″). The coating is typically composed of a series of sub-layers composed of mostly titanium nitride, aluminum oxide, and titanium carbon nitride. This thin layer directly enhances the performance of the inserts by increasing their hardness and insulating the heat generated from the cut to the substrate.

Coating Technologies:

CVD (Chemical Vapor Deposition) –

As its name suggests, in this process the coating forms a chemical bond with the substrate. Therefore, the adhesion to the substrate is very strong. With CVD, it is possible to create a thick coating of 5 to 25 microns. Due to its thicker layer, CVD provides excellent heat insulation and enables achieving higher cutting speeds compared with PVD. The downside is more sensitivity to cracks and fractures.

PVD (Physical Vapor Deposition) –

In the PVD process, the coating layer is spattered on the substrate and does not form a chemical bond with it. Therefore, the adhesion is lower, but the process induces compressive residual stress that improves the overall toughness of the carbide insert. PVD is good for creating thin coatings between 1 to 8 microns. PVD-coated inserts need to operate at lower cutting speeds when compared with CVD, however, they are tougher, have a smoother surface (less friction), and can be applied also on sharper edges (small honing and ground inserts).

As a machinist, you need to understand when to prefer a thinner or thicker coating layer and when to prefer a CVD or a PVD insert!

Coating Selection Guide

| Materials | Turning | Milling |

|---|---|---|

| P | CVD | PVD |

| M | Thin CVD | PVD |

| K | CVD | PVD or Thin CVD |

| N | Uncoated | Uncoated |

| S | Thin PVD | PVD |

Post Treatment

All coatings have flaws in their surface uniformity caused by coating droplets and non-uniform grain size. Most modern grades add a post-treatment after the coating process. This treatment is usually sandblasting or tumbling, aiming to smoothen the finial coating layer, thus reducing the friction and, as a result, also the generated heat.

Carbide Grades Designations

Although there is no formal standard, most of the major carbide inserts suppliers follow the following guidelines for their Carbide Grades designation:

| B | B | S | S | H | H |

- BB – Brand: Each brand uses a different 2-letter combination as a prefix. (Some brands have several prefixes associated with them). Iscar uses “IC“, Sandvik uses “GC“, and Kennametal “KC“, and so on. Examples: IC808, GC4315, KCU25.

- SS – Coating Series (Family): For example, Sandvik grades GC4305, GC4315, and GC4325 share the same 43 series coating. In this example, “43” is a family of thick CVD-coated grades for steel.

- HH – Hardness Level: The last two digits, in most cases, reflect the hardness level. A smaller number will usually mean a harder substrate. For example, GC4305, GC4315, GC4325, and GC4335 have the same coating. GC4305 is the hardest in the series, and GC4335 is the toughest (Least hard) in the series. While it is not a 100% rule (because the carbide suppliers don’t always follow these guidelines), It is still beneficial to be familiar with this system.