What is the Substrate of a Carbide Grade?

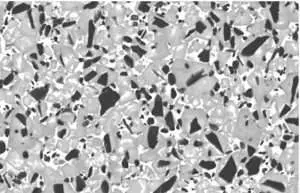

The substrate is the material of the bare cutting insert before coating and post-treatment. It is composed of 80-95% of WC. WC (also referred to as Wolfram) is a combination of tungsten (W) and carbon (C) refactored together. To give the substrate the desired properties, the manufacturers add various alloying elements. The main alloying element is 5-15% of cobalt (Co), which increases the substrate’s toughness (More cobalt=more toughness, Less cobalt=more hardness). The primary property of interest to the machinist is the hardness of the substrate. Very hard substrates have a hardness of 1800 HV and provide excellent wear resistance but are very brittle and can work only in very stable conditions. Very tough substrates have a hardness of about 1300 HV. They can operate only at lower cutting speeds, will wear out faster, but have much better resistance to interrupted cuts and unfavorable conditions. The right balance between hardness and toughness is critical for achieving a longer tool-life and higher productivity in each application.

Substrate Hardness Selection Guide

| Material | Continues | Semi | Interuppted |

|---|---|---|---|

| P | Hard | Medium | Tough |

| M | Hard | Medium | Tough |

| K | Hard | Medium-Hard | Medium |

| N | Hard | Medium-Hard | Medium |

| S | Hard | Medium-Hard | Tough |