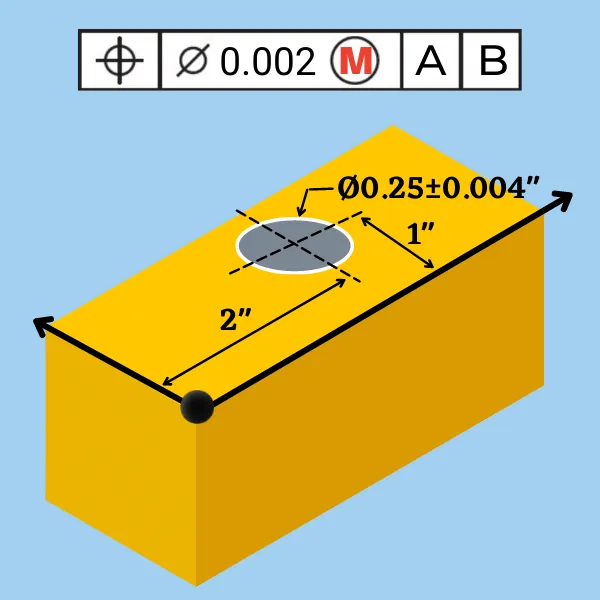

Maximum Material Condition (MMC) is a GD&T symbol indicating the maximum or minimum allowed tolerance of a feature where it has the maximum amount of material (volume/size).

- In a hole/bore, MMC = Minimum allowed diameter according to the tolerance.

- In a Shaft/pin, MMC = Maximum allowed diameter according to the tolerance.

MMC defines the worst-case scenario of a part that will still guarantee the assembly between pin(s) and hole(s). When a bore is at its smallest and a pin is at its largest diameter, we can be sure that we will still be able to assemble that part. Thus, MMC is widely used in cases where clearance fits are needed.

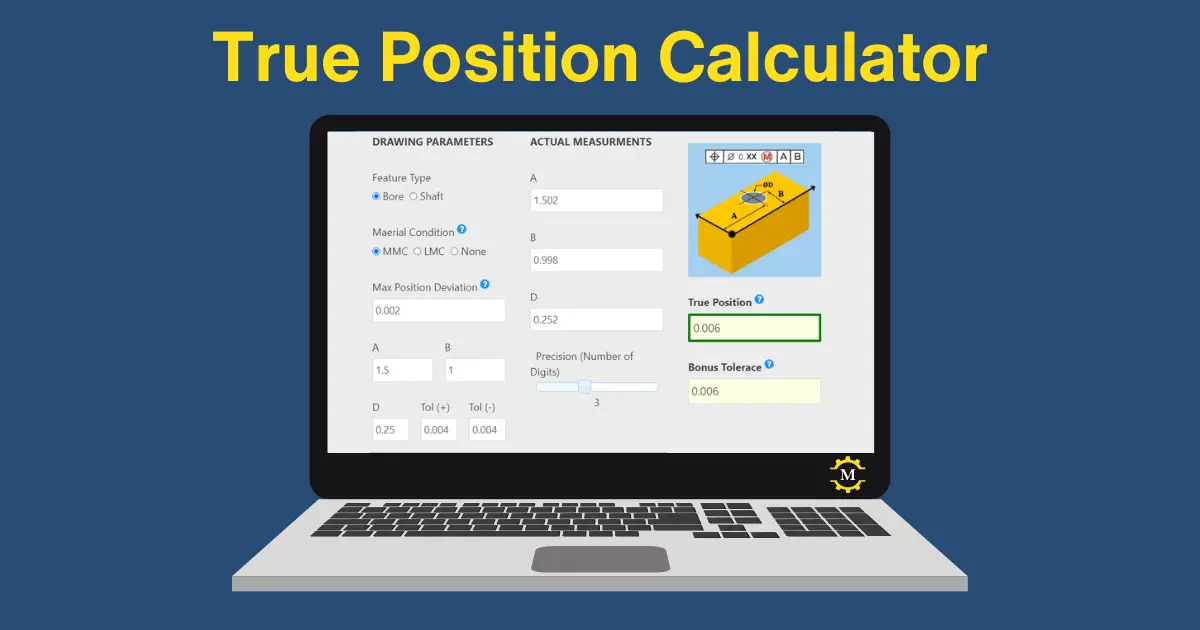

Combining true position with MMC is very powerful. It means that the maximum allowed position deviation (3) is considered where the feature’s size is at its maximum material condition. As the difference between the feature’s measured size and its MMC grows, you use a bigger tolerance on the position. This additional tolerance range is called Bonus Tolerance. (see example below).

« Back to Glossary Index