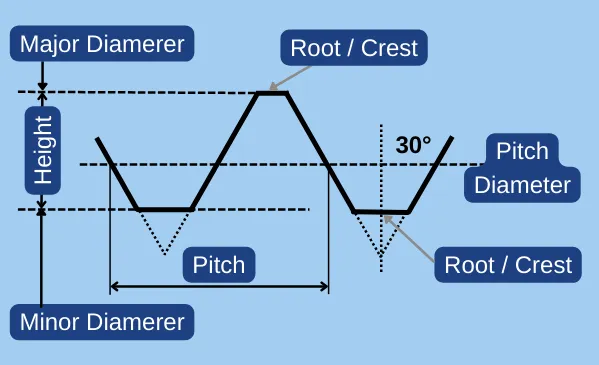

Basic Thread Dimensions

| Property | Inch | mm |

|---|---|---|

| Nominal Diameter | 0.875 | 22.225 |

| Pitch (TPI) | 9 | |

| Pitch (Distance) | 0.1111 | 2.822 |

| Pitch Diameter | 0.8028 | 20.391 |

| Minor Diameter | 0.7427 | 18.865 |

| Thread Height | 0.0601 | 1.527 |

| Addendum | 0.0361 | 0.917 |

| Crest (External) Root (Internal) |

0.0139 | 0.353 |

| Tap Drill Size (75% depth) |

0.767 | 19.47 |

| Lead Angle (Single Start) |

2.52° | |

| Thread Family | Unified Coarse Pitch (UNC) | |

| Relevant Standards | ASME B1.1-2003 | |

| Equivalent MetricThread | M22 |

For more threading data scroll down, or use the Thread Calculator

Choose the Threading Data you want to explore

7/8 - 9 UNCPossible Thread Classes

7/8 - 9 UNC 1A (External)

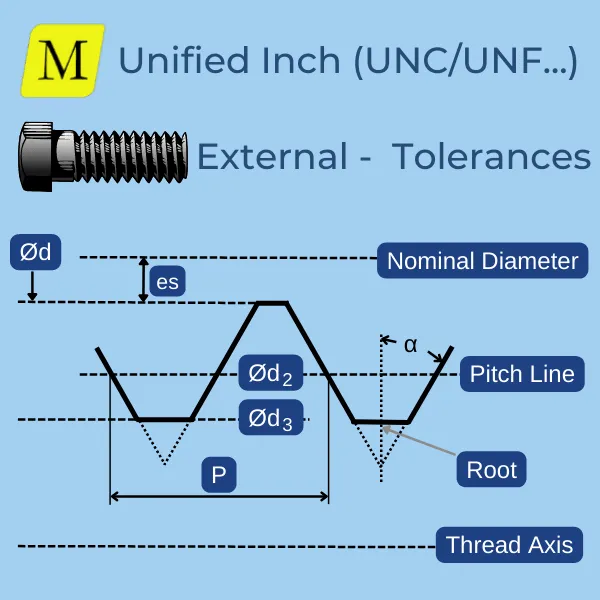

* Permisable values for thread Class 1A

| # | Description | Value (Inch) | Value (mm) |

|---|---|---|---|

| es | Allowance | 0.0018 (Ref) | 0.046 (Ref) |

| d | Major Diameter | 0.8524 - 0.8732 | 21.651 - 22.179 |

| d2 | Pitch Diameter | 0.792 - 0.801 | 20.117 - 20.345 |

| d3 | Minor Diameter (UNR Only) | 0.7409 (Ref) | 18.819 (Ref) |

| α | Varation of 30° anngle (+/-) | 0.75° | |

| P | Varation of pitch (+/-) | 0.0026 (Ref) | 0.066 (Ref) |

* Values are calculated for Length of engagement of 5xPitch. For calculations of different engagement length use the Thread Calculator'

* Back to Thread Class Selection

7/8 - 9 UNC 2A (External)

* Permisable values for thread Class 2A

| # | Description | Value (Inch) | Value (mm) |

|---|---|---|---|

| es | Allowance | 0.0018 (Ref) | 0.046 (Ref) |

| d | Major Diameter | 0.8593 - 0.8732 | 21.826 - 22.179 |

| d2 | Pitch Diameter | 0.795 - 0.801 | 20.193 - 20.345 |

| d3 | Minor Diameter (UNR Only) | 0.7409 (Ref) | 18.819 (Ref) |

| α | Varation of 30° anngle (+/-) | 0.75° | |

| P | Varation of pitch (+/-) | 0.0017 (Ref) | 0.043 (Ref) |

* Values are calculated for Length of engagement of 5xPitch. For calculations of different engagement length use the Thread Calculator'

* Back to Thread Class Selection

7/8 - 9 UNC 3A (External)

* Permisable values for thread Class 3A

| # | Description | Value (Inch) | Value (mm) |

|---|---|---|---|

| es | Allowance | 0 (Ref) | 0 (Ref) |

| d | Major Diameter | 0.8611 - 0.875 | 21.872 - 22.225 |

| d2 | Pitch Diameter | 0.7983 - 0.8028 | 20.277 - 20.391 |

| d3 | Minor Diameter (UNR Only) | 0.7427 (Ref) | 18.865 (Ref) |

| α | Varation of 30° anngle (+/-) | 0.75° | |

| P | Varation of pitch (+/-) | 0.0013 (Ref) | 0.033 (Ref) |

* Values are calculated for Length of engagement of 5xPitch. For calculations of different engagement length use the Thread Calculator'

* Back to Thread Class Selection

7/8 - 9 UNC 1B (Internal)

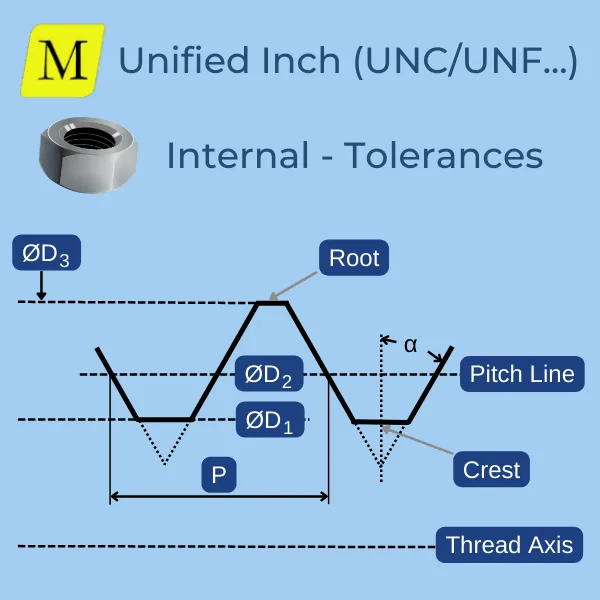

* Permisable values for thread Class 1B

| # | Description | Value (Inch) | VValue (mm) |

|---|---|---|---|

| D1 | Minor Diameter | 0.755 - 0.778 | 19.177 - 19.761 |

| D2 | Pitch Diameter | 0.8028 - 0.8145 | 20.391 - 20.688 |

| D | Major Diameter | 0.8750 (Min) | 22.225 (Min) |

| α | Varation of 30° anngle (+/-) | 0.75° | |

| P | Varation of Pitch (+/-) | 0.0034 (Ref) | 0.086 (Ref) |

* Values are calculated for Length of engagement of 5xPitch. For calculations of different engagement length use the Thread Calculator

* Back to Thread Class Selection

7/8 - 9 UNC 2B (Internal)

* Permisable values for thread Class 2B

| # | Description | Value (Inch) | VValue (mm) |

|---|---|---|---|

| D1 | Minor Diameter | 0.755 - 0.778 | 19.177 - 19.761 |

| D2 | Pitch Diameter | 0.8028 - 0.8106 | 20.391 - 20.589 |

| D | Major Diameter | 0.8750 (Min) | 22.225 (Min) |

| α | Varation of 30° anngle (+/-) | 0.75° | |

| P | Varation of Pitch (+/-) | 0.0023 (Ref) | 0.058 (Ref) |

* Values are calculated for Length of engagement of 5xPitch. For calculations of different engagement length use the Thread Calculator

* Back to Thread Class Selection

7/8 - 9 UNC 3B (Internal)

* Permisable values for thread Class 3B

| # | Description | Value (Inch) | VValue (mm) |

|---|---|---|---|

| D1 | Minor Diameter | 0.7547 - 0.7681 | 19.169 - 19.51 |

| D2 | Pitch Diameter | 0.8028 - 0.8087 | 20.391 - 20.541 |

| D | Major Diameter | 0.8750 (Min) | 22.225 (Min) |

| α | Varation of 30° anngle (+/-) | 0.75° | |

| P | Varation of Pitch (+/-) | 0.0017 (Ref) | 0.043 (Ref) |

* Values are calculated for Length of engagement of 5xPitch. For calculations of different engagement length use the Thread Calculator

* Back to Thread Class Selection

Tap Drill Sizes for 7/8 - 9 UNC

- If not specified, assume a thread depth of 75%.

- You can learn more about thread depth in tapping here.

- To get the tap drill size in other depths, use our Tap Drill Size Calculator .

| Thread Depth | Tap Drill Size (Inch) | Tap Drill Size (mm) |

|---|---|---|

| 55% | 0.796 | 20.21 |

| 60% | 0.788 | 20.02 |

| 65% | 0.781 | 19.84 |

| 70% | 0.774 | 19.66 |

| 75% | 0.767 | 19.47 |

| 80% | 0.759 | 19.29 |

| 85% | 0.752 | 19.11 |

Over Wire Measurements for 7/8 - 9 UNC

* OverWire is a measuring method to obatin the pitch diameter of threads. It is mostly used when a manufacturer does not have a Go/Nogo gauge for a thread. You can learn more about it here

| Inch | mm | |

|---|---|---|

| Permissible Wire Diameter Range | 0.0561 - 0.1123 | 1.426 - 2.851 |

| Ideal Wire Diameter | 0.0641 | 1.629 |

| Possible Wires From Standard Sets |

* 0.0642 * 0.0722 * 0.077 * 0.0825 * 0.0962 * 0.105 |

* 1.443 * 1.732 * 2.021 * 2.309 * 2.598 |

Once you know your wire diameter, you need to find out what is the premissable Measurement for your pitch diameter (Depending on the class). Use our Over Wire Calculator to find out!

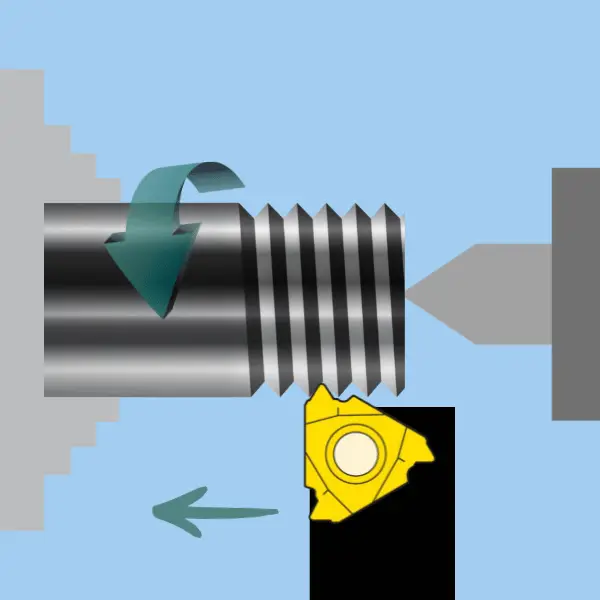

CNC Gcode Program for Turning of 7/8 - 9 UNC

The below sample Gcode is configured for:

- Fanuc Controller

- External RH Thread

- Right hand tool, machining towards the chuck

- Flank Infeed method with contant volume

- Flank Infeed method with contant volume

- Cutting conditions for steel

- Default number of passes

You can configure all the above parameters and much more in our Thread Turning Gcode Generator

%

O0100

(MACHINING DOCTOR - THREADING CNC PROGRAM)

(CONTROLER - FANUC A)

(THREAD - D=0.875 INCH, P=0.11111111111111 INCH, L=1.1111111111111 INCH)

(APPLICATION - EXTERNAL TURNING, TOWARDS CHUCK, RH TOOL, RH THREAD)

(FEED - 17 PASSES, FLANK, CONSTANT VOLUME)

(FINISH PASS - 0.001 INCH)

(WITH CHAMFER - NO)

G28 U0 W0

T0101 G99 G97 S1310 M03

G00 Z8.5

X 32.4 M08

G76 P010060 Q25 R0.025

G76 X18.763 Z-28.222 P1731 Q414 F2.822 R0.00

G28 U0 W0

M09

M30

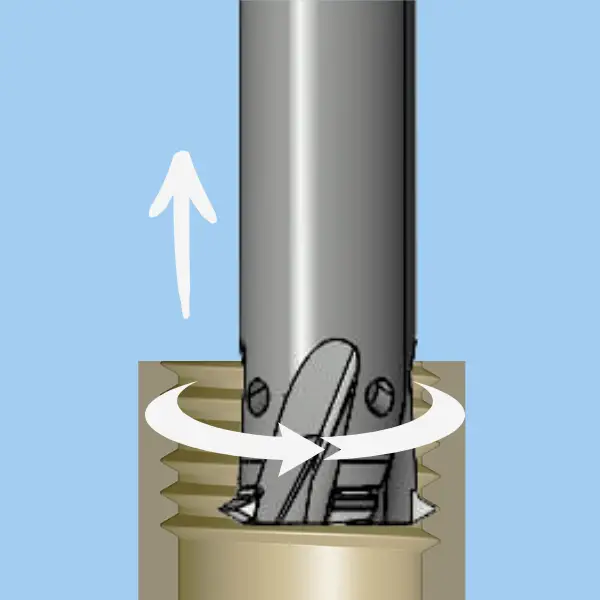

%CNC Gcode Program for Thread Milling of 7/8 - 9 UNC

The below sample Gcode is configured for:

- Fanuc Controller

- Internal RH Thread

- Climb Milling

- Cutter diameter: 70% of the thread diameter

- Single tooth Thread Mill cutter

- Cutting conditions for steel

- One radial pass

You can configure all the above parameters and much more in our Thread Milling Gcode Generator

%

O101

(WWW.MACHININGDOCTOR.COM - THREADMILLING PROGRAM)

(CONTROLER - FANUC)

(THREAD - D=0.875 INCH, P=0.11111111111111 INCH, L=1.1111111111111 INCH)

(APPLICATION - INTERNAL, RH THREAD, CLIMB MILLING)

(CUTTER - D=0.4375 [SINGLE TOOTH])

N1 M06 T1

G54

G90 G40 G17 G94 G21

G00 X0 Y0 S2619 M03

G43 H1 Z25.4 M08

(M-CODE "THROUGH COOLANT ON")

(PASS 1 / 1)

G90 G01 Z-28.575 F2032

G91 G01 G41 D1 X2.7781 Y-2.7781 F399

G03 X2.7781 Y2.7781 Z0.3528 I0 J2.7781 F100

G03 Z2.8222 I-5.5563 J0 F200

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 Z2.8222 I-5.5563 J0

G03 X-2.7781 Y2.7781 Z0.3528 I-2.7781 J0

G01 G40 X-2.7781 Y-2.7781 F2032

G90 G00 Z25.4

M30

(PLEASE NOTE THIS GCODE HAS NOT BEEN TESTED ON YOUR MACHINE AND SETUP. WE CANNOT GUARANTEE ITS ACCURACY OR COMPATIBILITY. NOTE THAT YOU ARE USING IT AT YOUR OWN RISK, AND WE SHALL NOT BE HELD LIABLE FOR ANY DAMAGES OR LOSSES ARISING FROM THE USE OF THIS PROGRAM.)

%