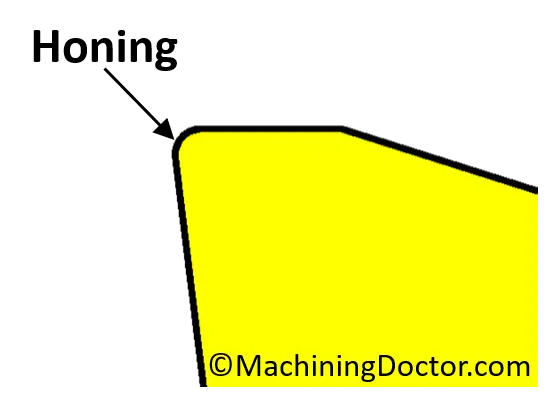

Honing is a process that rounds the tip of the cutting edge, typically to a radius size is between 0.001-0.003″ (0.03-0.08 mm) . It is usually done with sandblasting. When an insert comes out of the production line it has a burr from the connecting line of the die set. The honing process eliminates the burrs. When inserts are ground the cutting edge comes out of the process with an RH of zero (Up Sharp). In most cases the insert will be honed also after grinding otherwise the cutting edge will be too sharp and very sensitive to breakages.

Typical honing values:

- Small Honing 0-0.01 mm – Machining small workpieces or thin walls. Can be found on small ground and positive turning inserts and solid carbide endmills.

- Average Honing 0.03-0.05 mm – A common honing size for finish and medium applications in turning and milling.

- Large Honing 0.06-0.08 mm – Used for heavy application or interrupted cuts.

Learn about more Cutting Edge Parameters

« Back to Glossary Index