Table of Contents

Although CMM measuring machines took away many of the traditional use cases of the sine bar, It is still the most accurate method to measure the angle of a ground surface.

Likewise, the sine vice is still a very effective holding device to grind an inclined plane at a precise angle on a manual surface grinder.

Sine Bar Calculator

(The calculator can be used also for sine plates and sine vises)

Sine Bar Formulas

(The below formulas are valid also for sine plates and sine vises)

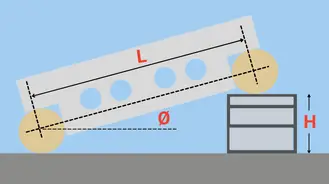

\( \large L = H \times \sin{\theta } \)

Explanation: The formulas are straightforward and are a result of the fact that the sine bar forms a right triangle:

- The Sine Bar length (L) is measured between the center of the cylinders and forms the triangle’s hypotenuse.

- The Sine Bar height (H) is the height of the stack of the gauge blocks placed under the cylinder and constitutes the triangle’s opposed leg.

- The angle (Theta) results from these two basic properties.

Sine Bar Principales

How does it work?

Sine bar is a simple yet very accurate method to measure the angle of a part. It is built from a precision ground plate sitting on two precision ground cylinders, where the distance between the cylinders is a known whole number. (like 5″ or 100 mm)

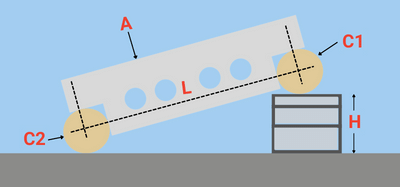

You need a Sine bar from a reputable manufacturer that guarantees the device’s accuracy across the board to get a precise result. The overall accuracy is a combination of several factors:

- The accuracy and uniformity of the two cylinders (C1 and C2).

- The exact distance between the two-cylinder centers (Usually equal a whole number like 5 inches or 100 mm).

- The flatness of the top surface (A)

- The parallelism between the top surface (A) and the theoretical plane connecting the cylinder center lines (L).

- The accuracy of the gauge block stack (H).

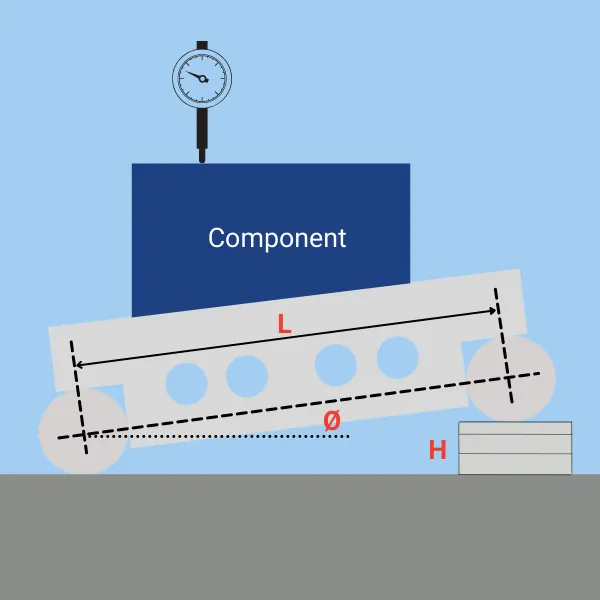

Measuring the angle of a small component:

- Calculate the needed height of the gauge block stack to level the plane horizontaly.

- Check the parallelism of the top surface with a dial indicator.

- If it is not close enough to zero, add or decrease the height of the stack.

- Repeat this step until reaching zero (or near zero) parallelism.

- Measure the total gauge block stack height.

- L is known from the Sinebar model.

- Calculate the actual angle:

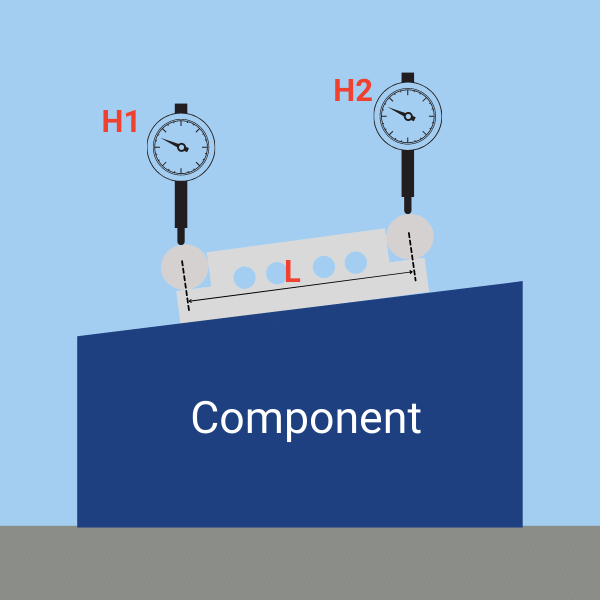

Measuring the angle of a large size component:

- L is known from the Sinebar model.

- Measure H1 & H2 with a Dial Height Gauge.

- Calculate the angle:

Types of Sine bars

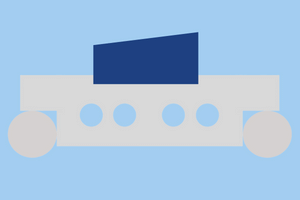

Sine Bar

Used to measure the angle of a flat area on a workpiece.

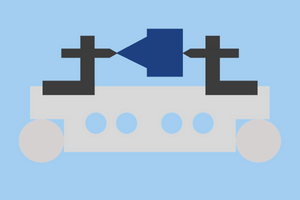

Sine center

This sub-type of a sine bar is used to measure the angle on cylindrical parts.

Sine Plate

A holding device used to hold a large workpiece at a precise angle to perform milling or grinding operations. The clamping of the components can be magnetic or mechanical.

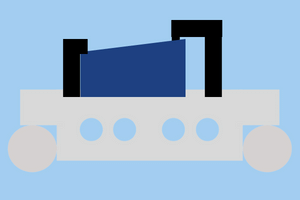

Sine Vice

This sub-type of a sine plate holds small components at a precise angle for machining (usually surface grinding).