This page is a collection of basic drilling calculators and formulas. Each topic includes an online calculator, formulas, and explanations. For easier use, you can toggle between the units (Metric/Imperial) and choose if to view everything or only the calculators (Hide the explanations and formulas)

This page includes only elementary calculators. For more complex topics, there is a separate page for each calculator. Go to the Machining Calculators Page for the complete list.

Choose a Drilling Calculator

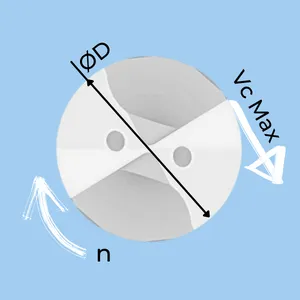

Cutting Speed Calculator and Formula

How to calculate the cutting speed based on the drill’s diameter and spindle speed)

- D – Drill diameter

- n – Spindle Speed

- C – Circumference.

- Vc – Cutting Speed

Theory

Cutting speed is the relative linear velocity between the cutting edge and the workpiece. At each point, the cutting speed is the product of the rotation speed of the drill (Spindle speed) and the circumference. In the drill’s center, the cutting speed is always zero, and it increases gradually as you get further away from the center. Therefore, in drilling, the term “cutting speed” refers to the Maximum Cutting Speed that occurs at the drill’s outer diameter. On the face of the drill, the cutting speed varies according to the distance from the center.

\( \large C = 2 \times \pi \times r = \pi \times D \)

\( \large V_c = n \times C \)

Formula in Imperial units

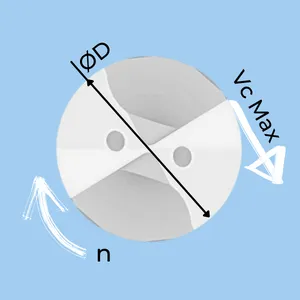

Spindle Speed Calculator and Formula

How to calculate the spindle speed based on the drill’s diameter and cutting speed

- D – Drill diameter.

- n – Spindle Speed.

- C – circumference.

- Vc – Cutting Speed

Theory

The drilling catalog or our experience tells us the cutting speed we need to use for a given application. On the other hand, the CNC machine is programmed with spindle speed. Therefore it is common that we need to compute the RPM from a given cutting speed either for programming or to ensure that the speed we want to run at is within the machine’s limit. It is calculated by dividing the cutting speed by the drill’s circumference.

Power Tip – Use our Speed and Feed Calculator to get the recommended cutting speed based on dozens of parameters!

\( \large C = 2 \times \pi \times r = \pi \times d \)

\( \large n= \frac{V_c}{C} \)

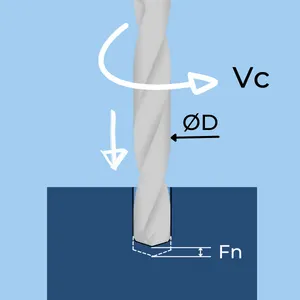

Penetration Rate Calculator and Formula

Determine how fast the drill is drilling based on the spindle speed and feed per revolution.

- n – Spindle Speed

- Fn – Feed / revolution

- Vf – Penetration Rate

Theory

The penetration rate in drilling is the linear speed at which the drill advances through the material. To calculate it, we first need to obtain the Feed per Revolution (Fn), which is the distance that the drill travels during one complete spindle rotation. This parameter is usually obtained from the supplier’s catalog. The penetration rate is the product of the spindle speed and the feed per revolution.

Formula (metric/inch)

- n – Spindle speed [RPM]

- fn – Feed per revolution [mm or Inch]

- Vf – Penetration rate [mm/min] or [IPM]

Metal Removal Rate Calculator and Formulas

The Drilling MRR Calculator determines the volume of material removed by the drill per minute in certain cutting conditions.

- D – Drill Diameter

- Fn – Feed/revolution

- Vc – Cutting Speed

- Q – MRR

Theory

The Metal roval rate (MRR) is measured in cubic inches (Or cubic cm) per minute and indicates how much material is machined in one minute of drilling at a set of cutting conditions. It is the product of the cutting speed, feed per revolution, and drill diameter. Learn more in our in-depth Metal Removal Page.

Drilling Time Calculator and Formulas

The Drilling Time Calculator determines how long it takes to complete a hole in certain cutting conditions.

- l – Depth of hole

- Vf – Penetration Rate

- T – Drilling Duration

Theory

The time it takes to drill a hole is simply the division of the bore depth by the penetration rate.